- Full Size 120" Wide Frame

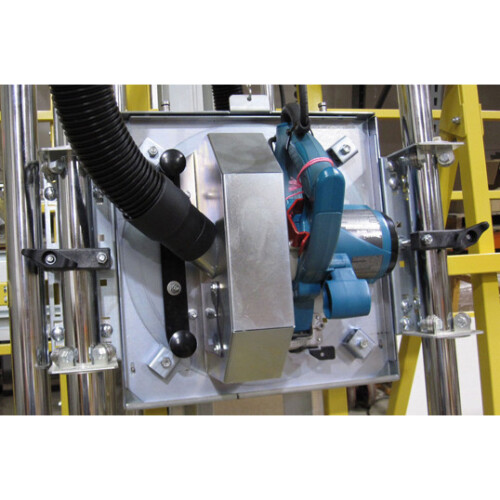

- Makita 5007F 7.25" saw

- Spinning saw insert plate

- Spring Hold Down

- Pivoting Knife Cutter

- Dust hood, hose, brush

- Folding Stand and Wheels

- Dual Rip Gauge

- Stop, Bar and Tapes

- Patented Accu-Square System

- Sealed Steel Bearings

-

Sign Shops cut a variety of material, not just wood, materials such as aluminum composites, corrugated plastics, foam board, PVC material, wood and much more. For some time, sign shops had to use different machines to cut each material. Thankfully, those days are gone, with the help of our Sign Maker’s Series. FS52SM model features a 120" wide frame and a 52" vertical cut.

Sign Shops cut a variety of material, not just wood, materials such as aluminum composites, corrugated plastics, foam board, PVC material, wood and much more. For some time, sign shops had to use different machines to cut each material. Thankfully, those days are gone, with the help of our Sign Maker’s Series. FS52SM model features a 120" wide frame and a 52" vertical cut. -

Out of stock

Motorized Sliding Bed – Increase spindle length 20” up to 40” • Motor & Switch – Beefy 3HP motor delivers ample power • Index Head – 3-Step, multi-V pulleys include 36 index positions • Control Box – Magnetic back positions controls anywhere on long bed • LCD Speed Display – Big easy-to-read speeds from 20 to 3850 RPMs • Banjo – Cast iron tool rest base is extra wide and sturdy

RIKON’s Heavy Duty 70-3040 Variable Speed Lathe features an innovative SLIDING BED that increases your turning capacity with just a turning of a switch! The special motorized upper bed effortlessly moves to the rightaway from the headstock to double the standard between-centers distance from 20” to 40”! Moving the sliding bed also increases the swing from 25-3/16” to 31-13/16” over the lower bed! Ideal for turning large bowls or platters. This space-saving lathe is extra heavy-duty, made of solid cast iron and steel construction to provide professional turners with a robust machine that will take the stress when turning large diameter bowls or spindles. The 3HP TEFC, 220V motor combined with 4 heavy-duty bearings in the headstock and digital speed controls provide all the power and precision needed for this versatile lathe.» Read Less

-

Designed with the exacting tolerances your shop demands, the SB1108 South Bend 15" Planer is top of its class in precision workmanship and dependability. The helical cutterhead delivers near mirror-smooth finishes right out of the gate. It consists of four rows of 52 indexable carbide inserts, each angled slightly to produce a shearing action. This shearing action results in less tearout in highly figured woods and quieter operation—and the planed surfaces are far superior to what you'll get with 15" straight-knife or other spiral cutterheads on the market. Other high-end features include a digital table height scale for ultra-precise and consistent thickness adjustments, precision-ground cast-iron tables, and triple belt drive—everything that makes this 15" planer truly live up to the South Bend name. The SB1108 manual was written by our U.S. based Technical Documentation Department and is packed with useful information. South Bend tools come with a 2-year warranty which covers parts and assures the unit is free from factory defects. The South Bend Customer Service and Technical Support Teams are U.S. based. Parts and accessories for the jointer are available online and shipped from the South Bend parts warehouse in Springfield, MO.

Designed with the exacting tolerances your shop demands, the SB1108 South Bend 15" Planer is top of its class in precision workmanship and dependability. The helical cutterhead delivers near mirror-smooth finishes right out of the gate. It consists of four rows of 52 indexable carbide inserts, each angled slightly to produce a shearing action. This shearing action results in less tearout in highly figured woods and quieter operation—and the planed surfaces are far superior to what you'll get with 15" straight-knife or other spiral cutterheads on the market. Other high-end features include a digital table height scale for ultra-precise and consistent thickness adjustments, precision-ground cast-iron tables, and triple belt drive—everything that makes this 15" planer truly live up to the South Bend name. The SB1108 manual was written by our U.S. based Technical Documentation Department and is packed with useful information. South Bend tools come with a 2-year warranty which covers parts and assures the unit is free from factory defects. The South Bend Customer Service and Technical Support Teams are U.S. based. Parts and accessories for the jointer are available online and shipped from the South Bend parts warehouse in Springfield, MO.No more messing around. This will be the last 15" planer you'll ever need to buy.

-

The 13" Combination Brush/Drum is the answer to your production bottleneck. Developed with mouldings in mind, this versatile sander can tackle every step in your finishing process, from sanding raw wood to sanding in between coats of stain or primer. Read about other applications below. This model features a 1-3/4 HP motor, and can handle stock up to 4" thick, or as thin as 1/32". It can also be equipped with an optional sanding drum for surface sanding.

The 13" Combination Brush/Drum is the answer to your production bottleneck. Developed with mouldings in mind, this versatile sander can tackle every step in your finishing process, from sanding raw wood to sanding in between coats of stain or primer. Read about other applications below. This model features a 1-3/4 HP motor, and can handle stock up to 4" thick, or as thin as 1/32". It can also be equipped with an optional sanding drum for surface sanding.- Raw Wood Sanding | White Wood Sanding

- Break sharp edges

- Open grain for even finish absorption

- Blend out minor defects

- Sealer Sanding | Primer Sanding | Scuff Sanding

- Removes raised fibers and grain (denib/defuzz)

- Degloss previously finished wood

- Clean reclaimed wood

- Wire Brushing

- Distress (weathered/Southwest finish)

- Pull out soft grain to create textured surface

Sanding Capacity: Maximum Width (in): 13 Minimum Length (in): 9 Maximum Thickness (in): 4, varies with drum/brush style Minimum Thickness (in): 1/32*Dimensions (in): 35L x 42W x 44HDrum (in): 5 x 13 extruded aluminum.Brush (in): 6-8 typical diameter.Speed: ranged variable RPM, 400-1200Dust Hood: 1- 4" port, hinged at back, 600 CFM min. recommendedConveyor Motor: 43 in.-lb. torque, ranged variable, 0-10 FPMDrive Motor (TEFC): 1-3/4 HPPower Requirements: 110 Volt, 20 amp serviceShipping Weight (lbs): 300 (approx., varies based on how equipped) - Raw Wood Sanding | White Wood Sanding

-

Out of stock

-

The DK1100 series of machines are the standard in the industry for drilling a single pocket hole at a time. We’ve packed a ton of functional features into these machines that set them apart from the competition. Choose from electric- or pneumatic-powered, freestanding or bench-mounted to fit the way you build. Each DK1100 machine is built with industrial-grade motors that provide the power to run day after day – quickly, quietly, and reliably – in even the most high-production environments. For most shops, this translates into previously unheard of productivity and efficiency.This model is identical to the DK1100 FP, but comes in a much smaller frame. It features a table height of 8", making it easy to build into your workbench or relocate from time to time. Requires a compressor able to produce 8 CFM at 120 PSI (50% duty cycle). Convenient Swing Stops Quickly position two pocket holes across rails of various widths by placing it against one stop, drilling the hole, and then repeating with the rail against the other stop. For drilling pocket holes in panels, the stops simply swing out of the way. Adjustable Fence Adjustments couldn’t be easier, as the fence adjusts directly from the top side of the machine to let you center a screw in 1/2"- to 1 1/2"-thick material. The clamp hold-down also adjusts to allow materials up to 4"-thick to be drilled. Quick Drill Bit Changes Changing drill bits is a quick and easy process. Simply loosen the collet with the provided Allen wrench, replace with a new bit, and you are back in production in less than 60 seconds. Long-Lasting Motors The industrial-grade motors used in Kreg machines are built for long-lasting service. Kreg machines are designed to minimize stress on moving parts, greatly reducing the likelihood of failure.

The DK1100 series of machines are the standard in the industry for drilling a single pocket hole at a time. We’ve packed a ton of functional features into these machines that set them apart from the competition. Choose from electric- or pneumatic-powered, freestanding or bench-mounted to fit the way you build. Each DK1100 machine is built with industrial-grade motors that provide the power to run day after day – quickly, quietly, and reliably – in even the most high-production environments. For most shops, this translates into previously unheard of productivity and efficiency.This model is identical to the DK1100 FP, but comes in a much smaller frame. It features a table height of 8", making it easy to build into your workbench or relocate from time to time. Requires a compressor able to produce 8 CFM at 120 PSI (50% duty cycle). Convenient Swing Stops Quickly position two pocket holes across rails of various widths by placing it against one stop, drilling the hole, and then repeating with the rail against the other stop. For drilling pocket holes in panels, the stops simply swing out of the way. Adjustable Fence Adjustments couldn’t be easier, as the fence adjusts directly from the top side of the machine to let you center a screw in 1/2"- to 1 1/2"-thick material. The clamp hold-down also adjusts to allow materials up to 4"-thick to be drilled. Quick Drill Bit Changes Changing drill bits is a quick and easy process. Simply loosen the collet with the provided Allen wrench, replace with a new bit, and you are back in production in less than 60 seconds. Long-Lasting Motors The industrial-grade motors used in Kreg machines are built for long-lasting service. Kreg machines are designed to minimize stress on moving parts, greatly reducing the likelihood of failure. -

-

Out of stock

The Byrd cutterhead is made from stress-proof steel for unrivaled durability, and it is ultra-efficient thanks to 74 carbide inserts that are arranged in spiral-shaped rows. These inserts have a four-inch radius ground into them and are mounted to approach your workpiece at a 14-degree angle, so you'll get a true shear cut every time you use it.

The Byrd cutterhead is made from stress-proof steel for unrivaled durability, and it is ultra-efficient thanks to 74 carbide inserts that are arranged in spiral-shaped rows. These inserts have a four-inch radius ground into them and are mounted to approach your workpiece at a 14-degree angle, so you'll get a true shear cut every time you use it.- Byrd helical cutterhead with 98 four-sided knife inserts provides smoother, quieter cutting and finer finish than conventional systems.

- Powerful 3HP TEFC motor controlled by magnetic switch for safety

- Three V-belts transfer maximum power to the cutterhead.

- Serrated steel infeed roller and smooth steel outfeed roller allow for 1/8-Inch maximum depth of cut and trouble-free operation.

- Large cast iron handwheel positions table quickly and easily.

-

Delta’s 36-L552 left tilt cabinet saw is ideal for woodworking, cabinet making, and boat building. It features up-front dual-crank controls with locking cams, speedometer style scales and a 52 inch Biesemeyer fence. The 5HP 220V motor cuts hardwoods and engineered products like MDF and melamine. The riving knife enables tool-less adjustment for through- and non-through cuts including grooves for shelves and picture frames as well as dadoes, rabbets, and cheek cuts for furniture. The single-cast trunion provides increased vibration control. Largest throat plate in category eases blade changes. Storage under the table board is convenient and expandable. Bi-level dust extraction improves dust collection. The 36-L500 is one of several pieces that make the 36-L552.

Delta’s 36-L552 left tilt cabinet saw is ideal for woodworking, cabinet making, and boat building. It features up-front dual-crank controls with locking cams, speedometer style scales and a 52 inch Biesemeyer fence. The 5HP 220V motor cuts hardwoods and engineered products like MDF and melamine. The riving knife enables tool-less adjustment for through- and non-through cuts including grooves for shelves and picture frames as well as dadoes, rabbets, and cheek cuts for furniture. The single-cast trunion provides increased vibration control. Largest throat plate in category eases blade changes. Storage under the table board is convenient and expandable. Bi-level dust extraction improves dust collection. The 36-L500 is one of several pieces that make the 36-L552.- Single-cast trunnion system results in incredible vibration control providing continuous smooth operation and dependable accuracy

- Dual Front Cranks make adjusting blade height and blade bevel easy, accurate, and repeatable in all your operations

- The Bevel Dial allows fine tuning of the blade bevel with ease and provides accuracy you can trust to within 1/4 degree

- The Cabinet Construction consists of a large cast-iron base providing stability and solid footing; True american marathon motor provides added power and is available in both 3 and 5 hp

-

Out of stock

Number of Knives 54 Helical Knife Size (L x W x T) (In.) 15 x 15 x 2.5 Cutterhead Diameter (In.) 3-1/16 Cutterhead Speed (RPM) 7,000 Cutting Capacity (W x D) (In.) 8 x 1/2 Table Size (L x W) (In.) 82 x 8 Table Height from Floor (In.) 31-5/16 Infeed Table Length (In.) 44 Outfeed Table Length (In.) 38 Rabbeting Capacity (In.) NA Fence Size (L x H) (In.) 44-3/4 x 38-3/16 Fence Tilt (Deg.) 45 Forward, 45 Backward Fence Positive Stops (Deg.) 45, 90, -45 Dust Collection Minimum CFM Required (CFM) 450 Dust Port Outside Diameter (In.) 4 Motor Power (HP) 2 Motor Phase 1 Motor Voltage (V.) 230 only Motor Current (Amps) 9 Recommended Circuit Size (Amps.) 20 -

This Extreme Table Saw is ideally suited to handling large panels without blinking an eye. A right-hand and rear-mounted extension table supports the widest panels before, during, and after the cut, and the large rail-mounted switch control won't get lost under the panel. Other features include ample storage shelves, a user friendly blade guard, a riving knife, a digital readout for blade angle and an efficient dust management system that includes an internal dust port and sloped cabinet floor that directs saw dust into the 4" dust port. Enjoy all of the innovative features this big capacity saw has to offer. CSA certified meeting CSA C22.2 #71.2-08, CSA C22.2 #105-1953, and UL 987 standards. Made in an ISO 9001 Factory. SPECIFICATIONS:

This Extreme Table Saw is ideally suited to handling large panels without blinking an eye. A right-hand and rear-mounted extension table supports the widest panels before, during, and after the cut, and the large rail-mounted switch control won't get lost under the panel. Other features include ample storage shelves, a user friendly blade guard, a riving knife, a digital readout for blade angle and an efficient dust management system that includes an internal dust port and sloped cabinet floor that directs saw dust into the 4" dust port. Enjoy all of the innovative features this big capacity saw has to offer. CSA certified meeting CSA C22.2 #71.2-08, CSA C22.2 #105-1953, and UL 987 standards. Made in an ISO 9001 Factory. SPECIFICATIONS:- Motor: 7-1/2 HP, 220V/440V*, 3-phase

- Amps 19.5/10

- Blade tilt: Left, 45 degrees

- Table height from floor: 35-3/4"

- Table size with extension 69-1/2" x 78-3/4"

- Arbor speed: 3600 RPM

- Arbor size: 1"

- Maximum dado width: 3/4"

- Maximum depth of cut @ 90°: 4"

- Maximum depth cut @ 45°: 2-3/4"

- Maximum rip capacity: 52"

- Distance from front of table to blade at maximum blade height: 11-1/2"

- Distance from front of table to center of blade: 17-1/4"

- Overall dimensions: 91-1/2" W x 79-1/2" D x 42-1/2" H

- Approximate shipping weight: 861 lbs.FEATURES:

- Precision-ground cast iron table

- Cast iron trunnions

- 3/8" x 3/4" T-slots & miter gauge

- 4" dust port

- Smooth and quiet Poly-V serpentine belt power transfer

- Steel cabinet

- Hinged motor cover

- Right hand and rear extension tables

- Magnetic switch with thermal overload protection and lock-out padlock

- Digital readout for bevel angle

- Quick-change between riving knife and splitter guard

- Includes 12" x 60T blade and push stick*If you require 440 volt operation, Grizzly must convert your machine at the time of purchase to maintain the machine's warranty. A $250 fee will be added to your order. Please allow extra shipping time for the conversion. If you need more information please contact technical service

-

Out of stock

The 13" Combination Brush/Drum is the answer to your production bottleneck. Developed with mouldings in mind, this versatile sander can tackle every step in your finishing process, from sanding raw wood to sanding in between coats of stain or primer. Read about other applications below. This model features a 1-3/4 HP motor, and can handle stock up to 4" thick, or as thin as 1/32". It can also be equipped with an optional sanding drum for surface sanding.

The 13" Combination Brush/Drum is the answer to your production bottleneck. Developed with mouldings in mind, this versatile sander can tackle every step in your finishing process, from sanding raw wood to sanding in between coats of stain or primer. Read about other applications below. This model features a 1-3/4 HP motor, and can handle stock up to 4" thick, or as thin as 1/32". It can also be equipped with an optional sanding drum for surface sanding.- Raw Wood Sanding | White Wood Sanding

- Break sharp edges

- Open grain for even finish absorption

- Blend out minor defects

- Sealer Sanding | Primer Sanding | Scuff Sanding

- Removes raised fibers and grain (denib/defuzz)

- Degloss previously finished wood

- Clean reclaimed wood

- Wire Brushing

- Distress (weathered/Southwest finish)

- Pull out soft grain to create textured surface

- Raw Wood Sanding | White Wood Sanding