-

Ironworker Max Force (Tons) 62 Oil Capacity (Gal.) 7 Speed (Strokes/Minute) 23 Throat Depth (In.) 8-7/8 5 Motor HP Hydraulic Pressure (PSI) 2500 Voltage 230 3 Phase 14 Amps Punching Station Pedestal Die Table 14 in Wide Flat Bar Shear Angle Shear Coper Notcher Metalworking

Ironworker Max Force (Tons) 62 Oil Capacity (Gal.) 7 Speed (Strokes/Minute) 23 Throat Depth (In.) 8-7/8 5 Motor HP Hydraulic Pressure (PSI) 2500 Voltage 230 3 Phase 14 Amps Punching Station Pedestal Die Table 14 in Wide Flat Bar Shear Angle Shear Coper Notcher Metalworking -

Out of stock

With a fully automatic feeding, cutting and lifting cycle this saw steps productivity up to the next level. The hydraulic vise uses a built-in power feed system to feed material to the desired length determined by a fine tunable sensor. Simply set your cut length, set the desired number of cuts and blade speed, load your material, and press start-the G0886 does the rest! With an impressive 12" x 14" capacity and powerful 3 HP, 3-phase motor, the G0886 has the capabilities to process some serious material. The workhorse also features a built-in 6 1/2 gallon coolant tank and full wrap catch basin to ensure coolant stays where it belongs. Perfect for cutting heavy steel or aluminum stock, you can quick and easily adjust downward feed rate to help maximize blade life. This saw truly does it all! Note: Stock must be at least 1" tall for auto feed to work.

With a fully automatic feeding, cutting and lifting cycle this saw steps productivity up to the next level. The hydraulic vise uses a built-in power feed system to feed material to the desired length determined by a fine tunable sensor. Simply set your cut length, set the desired number of cuts and blade speed, load your material, and press start-the G0886 does the rest! With an impressive 12" x 14" capacity and powerful 3 HP, 3-phase motor, the G0886 has the capabilities to process some serious material. The workhorse also features a built-in 6 1/2 gallon coolant tank and full wrap catch basin to ensure coolant stays where it belongs. Perfect for cutting heavy steel or aluminum stock, you can quick and easily adjust downward feed rate to help maximize blade life. This saw truly does it all! Note: Stock must be at least 1" tall for auto feed to work. -

Out of stock

Jet Vertical Milling Machines perfrom slot and keyway cutting, planning, drilling, diesinking, rebating and routing with surgical accuracy. With the addition of the Acu-Rite 200S 2 axis digital readout makes this unit readily useable for most applications.

Jet Vertical Milling Machines perfrom slot and keyway cutting, planning, drilling, diesinking, rebating and routing with surgical accuracy. With the addition of the Acu-Rite 200S 2 axis digital readout makes this unit readily useable for most applications. -

Out of stock

10 Horsepower 3-Phase 24" Wide Belt Wood Sander with Pneumatic Oscillation Control

These machines were developed in collaboration with James Goodall, a famous luthier, who wanted a machine that could sand very short and very thin pieces. This collaboration resulted in the introduction of the G9962Z & G9962ZX, which have become the "staple" of the guitar building industry. The main features that enable these sanders to process short pieces efficiently are the single drum and double infeed and outfeed pressure rollers positioned close to the drum. The result is a continuous downward pressure on extremely thin stock as short as 9", which is the distance between the first infeed and first outfeed pressure rollers. The feed belt is made of hard rubber to prevent distortion of thin stock while sanding. Features include digital read out, powered table elevation, variable speed conveyor, disc brake stopping system, pneumatic belt tracking, pneumatic belt oscillation, and separate motors for the drum, feed rollers, and table elevation. -

Out of stock

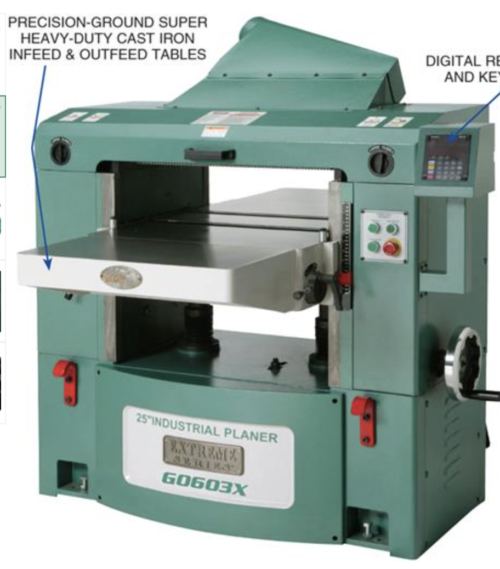

G0603X 25" 15 HP 3-Phase Extreme Duty Planer w/ Helical Cutterhead

Precision planing with digital control.

The G0603X 25" 3-Phase Extreme Duty Planer has an incredible 15 HP motor to make quick work of those big planing jobs. The G0603X features a unique helical cutterhead with 170 inserts rotated at 15° for smooth shearing cuts - meaning you can say goodbye to tear-out - while having an ultra-quiet machine and a smoother finish. The digital controls to allow you to simply enter the thickness of the board you want or the amount you want to remove, which saves time and reduces waste. All controls are conveniently located. The segmented chip breaker leads directly into the dust hood with a 5” dust port to help ensure the work area stays as clear as possible. And because it's a Grizzly Extreme Series®, you can be assured that your machine will provide years of reliable service. Like all Grizzly planers, the G0603X comes with a 1-year warranty which covers parts and assures the unit is free from factory defects. (Consumables are not covered by the warranty.) The G0603X manual was written by our U.S. based Technical Documentation Department and is packed with useful information. The Grizzly Customer Service and Technical Support Teams are U.S. based. Parts and accessories for the planer are available on-line and shipped from the Grizzly parts warehouse in Springfield, MO. Made in an ISO 9001 factory SPECIFICATIONS:- Cutterhead motor: 15 HP, 220V/440V*, 3-phase, 37A/18.5A

- Table elevation motor: 1/2 HP, TEFC, 2.4A/1.2A

- Table size: 25" W x 57" L

- Maximum cutting width: 25"

- Maximum stock thickness: 9"

- Maximum cutting depth: 1/4"

- Minimum stock thickness: 1/4"

- Minimum stock length: 10"

- Feed rate: 20, 25 & 30 FPM

- Cutterhead: 6-row helical, 170 inserts

- Cutterhead speed: 4900 RPM

- Power transfer: Triple V-belt

- Overall size with infeed/outfeed tables: 60-1/4"H x 57-3/8"W x 54-3/8"D

- Approximate shipping weight: 2054 lbs.

- Segmented chip breaker

- Precision-ground cast-iron table

- 5" dust port

- Micro-adjustable table height

- Infeed roller is serrated steel

- Outfeed roller is finely finished steel

- Digitally controlled table elevation for extreme accuracy

- Adjustable bed rollers

- Easy access cutterhead

- 3-Speed (20,25,30) feed Rate

- Inch/metric readout

- Emergency stop button*This machine is prewired for 220V. We can rewire to 440V in a few days’ time for a fee of $250. Please contact Grizzly Technical Support at (570)546-9663 before placing your order.

-

Out of stock

Description

Numeric control pad and digital readout provide the ultimate in precision. Other features include quick-change belt system with automatic belt tensioning, air-controlled automatic belt tracking system, motorized table elevation control, adjustable air-controlled belt oscillation system, and load meter. Certified to CSA and UL standards.Specifications

- Sanding motor: 10 HP, 220V, single-phase, 1725 RPM, 50A

- Feed motor: 1 HP, 220V, single-phase, 1725 RPM, 7A

- Elevation motor: 1/3 HP, 220V, single-phase, 1725 RPM, 3A

- Drum speed: 3550 FPM

- Drum diameter: 8"

- Feed rate: variable, 15–49 FPM

- Max. stock width: 24"

- Max. stock thickness: 6"

- Min. stock thickness: 1/8"

- Required air pressure: 75 PSI @ 7 CFM

- Sanding belt size: 25" x 60"

- Dust port: (2) 4"

- Emergency stop bar with brake

- Manual and motorized table elevation control

- Sanding load meter

- Digital readout and controls

- Made in an ISO 9001 factory

- Footprint: 39-1/4"W x 19-1/4"D

- Height with dust ports: 71"

- CSA certified meeting CSA C22.2 #105–1953 and UL 987–7 standards

- Approximate shipping weight: 1870 lbs.

California Proposition 65 Warning

-

Out of stock

The Grizzly Industrial G0445-24" 10 HP 3-Phase Platen Type Wide-Belt Sander machine was developed in collaboration with James Goodall, a famous luthier, who wanted a machine that could sand very short and very thin pieces. The main features that enable it to process short pieces efficiently are the single drum and the double infeed and double outfeed pressure rollers that are tucked in closer to the drum. The result is that you have continuous downward pressure on extremely thin stock as short as 14" (G0582). That is the distance between the first infeed and first outfeed pressure rollers. The feed belt is made of harder rubber to prevent distortion of thin stock while sanding. The new platen model will sand stock as short as 9" (G0445). All of these models include features like digital read out, powered table elevation, four screw jacks for table support, variable speed, disc brake stopping system, dust proof photo electric eye/pneumatic control for belt oscillation, and separate motors for the drum, the feed rollers, and the table elevation.

The Grizzly Industrial G0445-24" 10 HP 3-Phase Platen Type Wide-Belt Sander machine was developed in collaboration with James Goodall, a famous luthier, who wanted a machine that could sand very short and very thin pieces. The main features that enable it to process short pieces efficiently are the single drum and the double infeed and double outfeed pressure rollers that are tucked in closer to the drum. The result is that you have continuous downward pressure on extremely thin stock as short as 14" (G0582). That is the distance between the first infeed and first outfeed pressure rollers. The feed belt is made of harder rubber to prevent distortion of thin stock while sanding. The new platen model will sand stock as short as 9" (G0445). All of these models include features like digital read out, powered table elevation, four screw jacks for table support, variable speed, disc brake stopping system, dust proof photo electric eye/pneumatic control for belt oscillation, and separate motors for the drum, the feed rollers, and the table elevation. -

Out of stock

FEATURES: • Dual mitering allows for compound angle cutting of 60° right and 45° left • Tungsten carbide blade guides with precision bearings, stabilizes the blade for increased accuracy and extendes blade life • Large handwheel with blade tensioning gauge acurately measures blade pressure • For added safety, the EHB-1018VM Bandsaw follows strict guidelines and electrical requirements to be certified by CSA Group • Quick positioning vise for clamping of materials • The Elite swing away panel relocates saw controls to a single location, offering finger-tip operation of most major saw functions. • Semi-automatic bow raises after cut to predetermined height • Automatic blade breakage sensor detects accidental breakage and interrupts the power • Heavy-duty construction reduces vibration and deflection • Blade is fully guarded for operators safety

FEATURES: • Dual mitering allows for compound angle cutting of 60° right and 45° left • Tungsten carbide blade guides with precision bearings, stabilizes the blade for increased accuracy and extendes blade life • Large handwheel with blade tensioning gauge acurately measures blade pressure • For added safety, the EHB-1018VM Bandsaw follows strict guidelines and electrical requirements to be certified by CSA Group • Quick positioning vise for clamping of materials • The Elite swing away panel relocates saw controls to a single location, offering finger-tip operation of most major saw functions. • Semi-automatic bow raises after cut to predetermined height • Automatic blade breakage sensor detects accidental breakage and interrupts the power • Heavy-duty construction reduces vibration and deflection • Blade is fully guarded for operators safety -

Out of stock

Vertical Band Saw Voltage 230 2 HP 50 to 5000 sfpm Speeds Max Thickness of Cut 20 In. Max Blade Length 151-1/2 In. Corded Max Blade Width 1 In. Blade Thickness 0.025 In. Overall Height 77-1/2 In. Overall Width 29 In. Overall Depth 40 In. Cutting Angle 10 Degrees Left and 45 Degrees Right 1725 RPM 3 Phase 60 Hz Features Variable Speed Drivetrain Allows Operators to Fine Tune The Blade Speed Fast and Easily Table Dimensions 24 in x 22 In. Application Metal

Vertical Band Saw Voltage 230 2 HP 50 to 5000 sfpm Speeds Max Thickness of Cut 20 In. Max Blade Length 151-1/2 In. Corded Max Blade Width 1 In. Blade Thickness 0.025 In. Overall Height 77-1/2 In. Overall Width 29 In. Overall Depth 40 In. Cutting Angle 10 Degrees Left and 45 Degrees Right 1725 RPM 3 Phase 60 Hz Features Variable Speed Drivetrain Allows Operators to Fine Tune The Blade Speed Fast and Easily Table Dimensions 24 in x 22 In. Application Metal -

Out of stock

Elite Vertical Bandsaws are the perfect blend of power and balance. Featuring variable speed drivetrains with precision balanced cast-iron blade wheels with a bonded rubber blade track, precision ground articulating table, 4.2 KVA Bi-Metal Blade stations, and CSA / CUS Certification make Elite vertical bandsaws the choice for precision sawing of ferrous and non-ferrous materials.

Elite Vertical Bandsaws are the perfect blend of power and balance. Featuring variable speed drivetrains with precision balanced cast-iron blade wheels with a bonded rubber blade track, precision ground articulating table, 4.2 KVA Bi-Metal Blade stations, and CSA / CUS Certification make Elite vertical bandsaws the choice for precision sawing of ferrous and non-ferrous materials. -

Out of stock

Stock Number 311440 Compound Slide Travel (In.) 3-1/2 Cross Slide Travel (In.) 7 Distance Between Centers (In.) 40 Drive EVS Gross Weight (Lbs) 1584 Input Power 230V 3ph Length of Gap (In.) 9-1/2 Max Tool Size (In.) 3/4 x 3/4 Motor (HP) 3 HP, 230V, 3-Phase Motor Phase 3 Motor Power (HP) 3 Motor Voltage (V.) 230 Net Weight (Lbs.) 1320 Number of Inch Threads 34.0000 Number of Longitudinal and Cross Feed Rates 25 Number of Metric Threads 34.0000 Number of Spindle Speeds Variable Overall Dimensions (L x W x H) (In.) 68.5 x 28.3 x 50 Prewired Voltage (V.) 230 Prop 65 Cancer and Reproductive Harm Range of Cross Feeds (IPR) 25 Range of Inch Threads (TPI) 2-56 Range of Longitudinal Feeds (IPR) 0.0016-0.0460 Range of Metric Threads 0.5-12 Range of Spindle Speeds (RPM) 40-2000 Shipping Dimensions (L x W x H) (In.) 76 x 30 x 61 Spindle Bore (In.) 1-1/2 Spindle Mount D1-4 Spindle Taper Morse #5 Spindle Taper with Sleeve MT-5 Spindle Thread (In./TPI) 2 - 56 Steady Rest Capacity (In.) 0.23-0.61 Copper Shaft ( Standard) 0.20-2.36 Bearing Roller(OP) Swing Over Bed (In.) 14 Swing Over Cross Slide (In.) 9-1/16 Tailstock Spindle Travel (In.) 6-1/8 Taper in Tailstock Spindle MT-3 Weight (Lbs.) 1584 Width of Bed (In.) 7.48