- Sanding motor: 15 HP, 220V/440V*, 3-phase, 36A/18A, 1725 RPM

- Conveyor motor: 1 HP, 220V/440V*, 3-phase, 3.4A/1.7A

- Table elevation motor: 1/4 HP, 220V/440V*, 3-phase, 1.2A/0.6A, 1725 RPM

- Max. board width: 36-1/2"

- Max. board thickness: 6"

- Min. board length: 14"

- Air requirements: 75 PSI

- Surface speed of drums: 2565 FPM

- Conveyor feed rate: Variable, 15-49 FPM

- Built-in air filter/regulator

- Independent motor control

- Pneumatic belt tracking and tensioning

- Digital sanding load meter

- Emergency stop bar

- Digital readout and control panel

- Three 4" dust ports

- Steel cabinet

- Steel outfeed drum

- Rubber infeed drum

- Rubber pressure rollers

- Micro-adjustable graphite/felt platen

- CSA certified meeting CSA C22.2 #105-1953 and UL 987-7 standards

- Overall size: 52-1/8"W x 69-5/8"H x 49-3/8"D

- Approximate shipping weight: 1800 lbs.

- *440V operation requires purchase of additional components

-

Out of stock

Door builders and cabinet shops will love the extra capacity of this 37" wide-belt sander. With a 15 HP 3-phase sanding motor, this wide-belt is built for daily industrial use with features such as a heavy-duty steel cabinet, pneumatic belt oscillation, and a built-in air filter/regulator. The digital control pad automates table adjustments and is accurate to 0.005". Also, the variable-speed conveyor, adjustable oscillation controls, and adjustable graphite/felt platen easily allow the operator to find the perfect combination of settings to achieve soft, smooth finishes on all types of wood. Made in an ISO 9001 Factory CSA certified meeting CSA C22.2 #105-1953 and UL 987-7th standards! Specifications

Door builders and cabinet shops will love the extra capacity of this 37" wide-belt sander. With a 15 HP 3-phase sanding motor, this wide-belt is built for daily industrial use with features such as a heavy-duty steel cabinet, pneumatic belt oscillation, and a built-in air filter/regulator. The digital control pad automates table adjustments and is accurate to 0.005". Also, the variable-speed conveyor, adjustable oscillation controls, and adjustable graphite/felt platen easily allow the operator to find the perfect combination of settings to achieve soft, smooth finishes on all types of wood. Made in an ISO 9001 Factory CSA certified meeting CSA C22.2 #105-1953 and UL 987-7th standards! Specifications -

This industrial bandsaw is huge, great attention has been given to the fine points that make it easy to use and performance perfection. The tilt mechanism is manufactured from two pieces of solid cast iron that slide within each other in a dovetail system. There is an ergonomically designed foot brake that shuts the motor off automatically, and easy blade change make operating this bandsaw a joy.

This industrial bandsaw is huge, great attention has been given to the fine points that make it easy to use and performance perfection. The tilt mechanism is manufactured from two pieces of solid cast iron that slide within each other in a dovetail system. There is an ergonomically designed foot brake that shuts the motor off automatically, and easy blade change make operating this bandsaw a joy. -

Out of stock

The POWERMATIC 25-Inch wide belt sander delivers the utmost performance in measurement and sanding, creating a flawless finish every time. The sander has centralized controls which allow the user to access all the needed buttons on one simple panel for more convenience.

The POWERMATIC 25-Inch wide belt sander delivers the utmost performance in measurement and sanding, creating a flawless finish every time. The sander has centralized controls which allow the user to access all the needed buttons on one simple panel for more convenience.- Centralized controls allow you to access all the needed buttons on one simple panel

- The auto thicknesses will capture the piece of wood to give the user the exact starting thickness

- The variable speed feed belt allows you to accurately dial in the exact feed speed to best suit your project

- Digital readout will show the user the exact thickness of the finished piece, or will allow you to preset exactly the thickness you prefer for the finished piece

- The disc brake slows the machine quickly and will activate immediately to stop machine in an emergency

-

Out of stock

The JET JTM-4VS-1 Mill with 3-Axis ACU-RITE VUE DRO (Knee) with X-Axis powerfeed is a variable speed milling machine with a 3-Axis digital readout, with the third Axis on the Knee provides computer assisted precision. The powerfeed provides easier movement and better repeatability. JET mills deliver performance and precision and are backed by an industry leading 2-year warranty.

The JET JTM-4VS-1 Mill with 3-Axis ACU-RITE VUE DRO (Knee) with X-Axis powerfeed is a variable speed milling machine with a 3-Axis digital readout, with the third Axis on the Knee provides computer assisted precision. The powerfeed provides easier movement and better repeatability. JET mills deliver performance and precision and are backed by an industry leading 2-year warranty. -

Out of stock

Designed for fast, consistent, low-effort production, this 25” industrial planer lets you set the bed height through a programmable logic controller. No more turning a handwheel to find your thickness!

Designed for fast, consistent, low-effort production, this 25” industrial planer lets you set the bed height through a programmable logic controller. No more turning a handwheel to find your thickness!-

-

- 10 hp motor has enough muscle to smooth full 25” boards.

- Spiral cutter head (included) spins at 5,000 rpm.

- Rows of rotatable carbide blades make the spiral cutter head last much longer and work more quietly than a straight-knife cutter.

- Runs on 220-volt single-phase power, so you can use this sophisticated machine in almost any shop.

- Can smooth off up to .25” of material at one time.

- Variable speed from 20 to 30 feet per minute, so you can finetune to get the exact speed you need for your material and finish.

- 25” x 32” main cast iron table expands to an even larger 25” x 57”, supporting your material and helping you create straight, smooth boards.

- Programmable controller makes it simple to set the height. Just enter what you want, and the bed automatically moves to that setting.

- Controller includes automatic backlash compensation to produce exact, repeatable thicknesses.

- Segmented steel infeed roll allows you to smooth multiple boards with different heights at once, increasing your productivity.

- Durable dual steel outfeed roll moves boards along to the cutting head.

- You can set the quick-adjust bed rolls high to reduce friction on rough-sawn stock, or adjust them lower for straighter, smoother results.

- Segmented chip breaker prevents large chips or strips of wood from clogging up the machine or your dust collector.

- Solid iron pressure bar applies even force across the boards to avoid chipping.

- Anti-kickback fingers grip the material so it’s less like to shoot back out if there’s a problem at the cutter head.

- Oversized bearing housings ensure quiet performance and long life.

-

- .

-

-

Out of stock

The POWERMATIC® WP2510 Planer has a solid steel helical cutterhead with four-sided carbide knife inserts that require no adjustments when changing. With a digital readout and simple PC controller, setting up table heights is quick and easy. The frame is machined from heavy cast iron and has extra wide side panels that offer rigid bed support and ensure accurate alignment. The planer's segmented, serrated infeed roll with segmented chip breakers has an independent yield of 1/4. Its automatically adjusting, chain drive gear box powers the 3" diameter infeed rollers, solid pressure bar and dual outfeed rollers for precise feeding of stock. The 3-speed feed selector gives woodworkers flexibility by changing feed rates quickly and easily. The WP2510 Planer has a large 32-3/16" x 26" precision-ground table which contains two adjustable table rollers for smooth feeding of uneven stock. The planer has a Quick-Set micro-adjustable lever that easily raises and lowers the table rollers from 0 to 0.05". The hood features a built-in 5" diameter dust chute. 1547399

The POWERMATIC® WP2510 Planer has a solid steel helical cutterhead with four-sided carbide knife inserts that require no adjustments when changing. With a digital readout and simple PC controller, setting up table heights is quick and easy. The frame is machined from heavy cast iron and has extra wide side panels that offer rigid bed support and ensure accurate alignment. The planer's segmented, serrated infeed roll with segmented chip breakers has an independent yield of 1/4. Its automatically adjusting, chain drive gear box powers the 3" diameter infeed rollers, solid pressure bar and dual outfeed rollers for precise feeding of stock. The 3-speed feed selector gives woodworkers flexibility by changing feed rates quickly and easily. The WP2510 Planer has a large 32-3/16" x 26" precision-ground table which contains two adjustable table rollers for smooth feeding of uneven stock. The planer has a Quick-Set micro-adjustable lever that easily raises and lowers the table rollers from 0 to 0.05". The hood features a built-in 5" diameter dust chute. 1547399 -

Out of stock

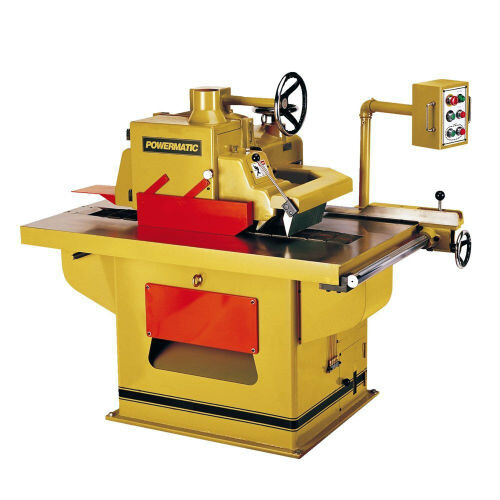

The SLR12 Straight line rip saw has every job covered. Powered by a 15 HP main motor, this saw has the capacity for virtually any job. The 12-Inch main blade mounts on a high alloy, heat treated arbor that is precision ground and dynamically balanced for maximum stability and long durability.

The SLR12 Straight line rip saw has every job covered. Powered by a 15 HP main motor, this saw has the capacity for virtually any job. The 12-Inch main blade mounts on a high alloy, heat treated arbor that is precision ground and dynamically balanced for maximum stability and long durability.- Full cast iron construction for rock-solid operation

- 15 HP Main Motor, 2 HP Feed Motor for large production capacity

- Auto-oiler with shut off, ensures long conveyor chain life

- Seven pressure rollers with dual anti-kickback devices help prevent stock discharge

- Variable feed speeds to accommodate different type stock

-

Out of stock

Jet dual mitering horizontal band saws unique design head dual miters both left and right for Quick angle cuts. The frequency inverter, unique to this saw, allows this EVS saw a full range of blade speeds.

Jet dual mitering horizontal band saws unique design head dual miters both left and right for Quick angle cuts. The frequency inverter, unique to this saw, allows this EVS saw a full range of blade speeds.