- Sliding headstock with electronic variable speed and digital RPM readout for accurate speed adjustments

- Spindle lock and built in spindle indexing on the headstock for drilling hole patterns, routing flutes and other equally spaced features

- Vacuum system provides quick method of chucking bowl blanks

- 15-amp quad receptacle for easy reach of powered accessories

- Two 100W task lamps provide ideal lighting [/fusion_checklist]

-

Out of stock

The Powermatic 4224B Lathe is designed to tackle the largest and most demanding woodworking projects, and it sports a slew of advanced features that will help make your job easier and improve the quality of your finished results. [fusion_checklist icon="check" iconcolor="#aaaaaa" circle="no"]

The Powermatic 4224B Lathe is designed to tackle the largest and most demanding woodworking projects, and it sports a slew of advanced features that will help make your job easier and improve the quality of your finished results. [fusion_checklist icon="check" iconcolor="#aaaaaa" circle="no"] -

Out of stock

-

Out of stock

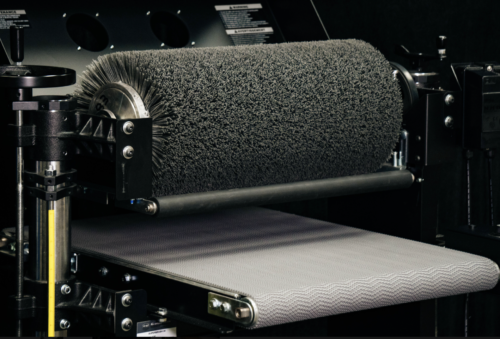

The production class Powermatic DDS-237 Dual Drum Sander that is loaded with features. A 10HP motor drives the dual steel drums, which have a hard durometer rubber coating to ensure a flat, mar free finish. Independently adjustable rear drum makes fine tuning easy. A heavy cast iron table incorporates four solid jackscrews with chain drive timing to keep it level at all times. The heavy-duty poly conveyor belt provides a positive grip on the stock. The 1/4HP feed motor is coupled to a two-speed forward/reverse gearbox that will sand 8 and 12 surface feet per minute. The heavy steel cabinet provides vibration free sanding, with plenty of storage space underneath.

The production class Powermatic DDS-237 Dual Drum Sander that is loaded with features. A 10HP motor drives the dual steel drums, which have a hard durometer rubber coating to ensure a flat, mar free finish. Independently adjustable rear drum makes fine tuning easy. A heavy cast iron table incorporates four solid jackscrews with chain drive timing to keep it level at all times. The heavy-duty poly conveyor belt provides a positive grip on the stock. The 1/4HP feed motor is coupled to a two-speed forward/reverse gearbox that will sand 8 and 12 surface feet per minute. The heavy steel cabinet provides vibration free sanding, with plenty of storage space underneath. -

Out of stock

The 16" Open-End Sander has front mounted controls and a load meter, which maintains a constant check during operation. Metal-tipped safety limiters inside the machine will stop the sander immediately should belt breakage occur. The combination head means a more consistent finish, and pneumatic conveyor belt tracking keeps belts automatically centered.

The 16" Open-End Sander has front mounted controls and a load meter, which maintains a constant check during operation. Metal-tipped safety limiters inside the machine will stop the sander immediately should belt breakage occur. The combination head means a more consistent finish, and pneumatic conveyor belt tracking keeps belts automatically centered. -

Includes 1 Brush & Caster Set SuperMax Tools offers a wide variety of SuperBrush™ sanders to meet the many needs of any woodworking shop. Our goal is to provide an excellent priced machine yielding an incredible return on investment by creating faster output, reduced rework, and greater product consistency. Just think of all the applications our machines can help with – here a just a few: • Raw Wood Sanding | White Wood Sanding • Break sharp edges • Blend out minor defects • Sealer Sanding | Primer Sanding | Scuff Sanding • Profile sanding • Clean reclaimed wood • Wire brushing to pull out soft grain to create textured surface These easy to use machines come with an extremely low learning curve and offer many different features which include: quick change brush heads, infinitely variable brush and conveyor speeds to allow for endless finish possibilities, adjustable tension rollers to prevent stock slippage, and precision height adjustments. Our SuperBrush™ sanders come in sizes ranging from 24” to 49” with single and/or double brush head offerings to meet all your finishing needs.Dozens of brush heads available to effectively sand a wide variety of applications.

Includes 1 Brush & Caster Set SuperMax Tools offers a wide variety of SuperBrush™ sanders to meet the many needs of any woodworking shop. Our goal is to provide an excellent priced machine yielding an incredible return on investment by creating faster output, reduced rework, and greater product consistency. Just think of all the applications our machines can help with – here a just a few: • Raw Wood Sanding | White Wood Sanding • Break sharp edges • Blend out minor defects • Sealer Sanding | Primer Sanding | Scuff Sanding • Profile sanding • Clean reclaimed wood • Wire brushing to pull out soft grain to create textured surface These easy to use machines come with an extremely low learning curve and offer many different features which include: quick change brush heads, infinitely variable brush and conveyor speeds to allow for endless finish possibilities, adjustable tension rollers to prevent stock slippage, and precision height adjustments. Our SuperBrush™ sanders come in sizes ranging from 24” to 49” with single and/or double brush head offerings to meet all your finishing needs.Dozens of brush heads available to effectively sand a wide variety of applications.- Raw Wood Sanding | White Wood Sanding

- Break sharp edges

- Open grain for even finish absorption

- Blend out minor defects

- Sealer Sanding | Primer Sanding | Scuff Sanding

- Removes raised fibers and grain (denib/defuzz)

- Degloss previously finished wood

- Clean reclaimed wood

- Wire brushing

- Distress (weathered/Southwest finish)

- Pull out soft grain to create textured surface

- Raw Wood Sanding | White Wood Sanding

-

Out of stock

This 6-foot box brake offers a happy medium between our 4-foot BB-4812 and our 8-foot BB-9612. With a welded steel frame, the BB-7212 offers years of hassle-free productivity.

This 6-foot box brake offers a happy medium between our 4-foot BB-4812 and our 8-foot BB-9612. With a welded steel frame, the BB-7212 offers years of hassle-free productivity.- Bends 12 gauge mild steel over its full 6-foot (72”) length.

- Maximum bend angle of 135°.

- 2 counterbalance weights make it easy to bend at maximum capacity and reduce operator strain.

- Electro-welded and truss-supported steel frame prevents distortion or twisting and produces high-quality bends.

- Comes standard with 17 hardened fingers of varying sizes (6 fingers of 3", 3 of 4", 6 of 5", and 2 of 6") .

- 3-piece finger design allows for a 6” box depth.

- You can set up a long straight brake or a segmented one for boxes or pans.

- Heavy-duty steel floor stand puts the beam at optimal working height.

-

Out of stock

For master craftsmen who strive for perfection with each project, the Powermatic CNC line is the premium choice. Providing unrivaled design, these machines deliver the eloquent tone of confidence needed to provoke one's imagination to endless possibilities. This is the CNC machine for the true craftsman

For master craftsmen who strive for perfection with each project, the Powermatic CNC line is the premium choice. Providing unrivaled design, these machines deliver the eloquent tone of confidence needed to provoke one's imagination to endless possibilities. This is the CNC machine for the true craftsman -

Out of stock

This 1,300-pound heavy duty cast iron planer offers rock solid rigidity and accurate planing for years to come. The hinged top allows easy access to the rollers and knives, and has a 5” dust port for easy attachment to any dust collection system. The cutterhead is a helical design with 125 four sided knife inserts – these produce a superior finish and much quieter operation compared to conventional cutterheads, and the inserts are installed without further adjustments. The anti-kickback fingers and pressure bar are located in close proximity to the cutterhead for an exceptional finish. Infeed and outfeed rollers are fitted with roller bearings for long life. The sectional infeed roller and chip breaker are specially designed to allow multiple boards to be planed at the same time. The adjustable bed rollers facilitate both rough and finish planing. The solid steel outfeed roller is machined with small serrations to insure a smooth finish yet provide positive feeding. The two-speed gearbox with machined detents is quickly changed up front when switching from rough to finish work. The massive, ribbed cast iron table is ground finished and rises smoothly via the hand wheel. With a hefty 7-1/2 horsepower motor, the 201HH Planer is perfect for the small to medium shop with continuous planing requirements. Product Listing with Warranty Period90 Days – Parts; Consumable items 1 Year – Motors, Machine Accessories 2 Year – Woodworking Machinery used for industrial or commercial purposes 5 Year – Woodworking Machinery

This 1,300-pound heavy duty cast iron planer offers rock solid rigidity and accurate planing for years to come. The hinged top allows easy access to the rollers and knives, and has a 5” dust port for easy attachment to any dust collection system. The cutterhead is a helical design with 125 four sided knife inserts – these produce a superior finish and much quieter operation compared to conventional cutterheads, and the inserts are installed without further adjustments. The anti-kickback fingers and pressure bar are located in close proximity to the cutterhead for an exceptional finish. Infeed and outfeed rollers are fitted with roller bearings for long life. The sectional infeed roller and chip breaker are specially designed to allow multiple boards to be planed at the same time. The adjustable bed rollers facilitate both rough and finish planing. The solid steel outfeed roller is machined with small serrations to insure a smooth finish yet provide positive feeding. The two-speed gearbox with machined detents is quickly changed up front when switching from rough to finish work. The massive, ribbed cast iron table is ground finished and rises smoothly via the hand wheel. With a hefty 7-1/2 horsepower motor, the 201HH Planer is perfect for the small to medium shop with continuous planing requirements. Product Listing with Warranty Period90 Days – Parts; Consumable items 1 Year – Motors, Machine Accessories 2 Year – Woodworking Machinery used for industrial or commercial purposes 5 Year – Woodworking Machinery -

Out of stock

This 1,300-pound heavy duty cast iron planer offers rock solid rigidity and accurate planing for years to come. The hinged top allows easy access to the rollers and knives, and has a 5” dust port for easy attachment to any dust collection system. The cutterhead is a helical design with 125 four sided knife inserts – these produce a superior finish and much quieter operation compared to conventional cutterheads, and the inserts are installed without further adjustments. The anti-kickback fingers and pressure bar are located in close proximity to the cutterhead for an exceptional finish. Infeed and outfeed rollers are fitted with roller bearings for long life. The sectional infeed roller and chip breaker are specially designed to allow multiple boards to be planed at the same time. The adjustable bed rollers facilitate both rough and finish planing. The solid steel outfeed roller is machined with small serrations to insure a smooth finish yet provide positive feeding. The two-speed gearbox with machined detents is quickly changed up front when switching from rough to finish work. The massive, ribbed cast iron table is ground finished and rises smoothly via the hand wheel. With a hefty 7-1/2 horsepower motor, the 201HH Planer is perfect for the small to medium shop with continuous planing requirements. Product Listing with Warranty Period90 Days – Parts; Consumable items 1 Year – Motors, Machine Accessories 2 Year – Woodworking Machinery used for industrial or commercial purposes 5 Year – Woodworking Machinery

This 1,300-pound heavy duty cast iron planer offers rock solid rigidity and accurate planing for years to come. The hinged top allows easy access to the rollers and knives, and has a 5” dust port for easy attachment to any dust collection system. The cutterhead is a helical design with 125 four sided knife inserts – these produce a superior finish and much quieter operation compared to conventional cutterheads, and the inserts are installed without further adjustments. The anti-kickback fingers and pressure bar are located in close proximity to the cutterhead for an exceptional finish. Infeed and outfeed rollers are fitted with roller bearings for long life. The sectional infeed roller and chip breaker are specially designed to allow multiple boards to be planed at the same time. The adjustable bed rollers facilitate both rough and finish planing. The solid steel outfeed roller is machined with small serrations to insure a smooth finish yet provide positive feeding. The two-speed gearbox with machined detents is quickly changed up front when switching from rough to finish work. The massive, ribbed cast iron table is ground finished and rises smoothly via the hand wheel. With a hefty 7-1/2 horsepower motor, the 201HH Planer is perfect for the small to medium shop with continuous planing requirements. Product Listing with Warranty Period90 Days – Parts; Consumable items 1 Year – Motors, Machine Accessories 2 Year – Woodworking Machinery used for industrial or commercial purposes 5 Year – Woodworking Machinery -

Out of stock

This 16-Inch jointer offers big capacity and performance in a machine that is loaded with features. Large center-mounted fence assembly adjusts easily on a rack and pinion system with ram lock. Preset stops on the fence body allow for fast angle set-up at 45-degree in and out, and a positive stop for perfect 90-degree angles. The parallelogram design keeps the table in close proximity to the cutterhead for improved finish and allows for a fast depth of cut adjustment. This design also ensures the tables remain perfectly parallel even after years of tough duty. The specially designed solid steel helical cutterhead consists of six rows of precision ground staggered inserts. This system makes fast work of knife changing and never needs adjustment. The heavy-duty 7-1/2 HP motor delivers all the power you need for even the biggest jobs.

This 16-Inch jointer offers big capacity and performance in a machine that is loaded with features. Large center-mounted fence assembly adjusts easily on a rack and pinion system with ram lock. Preset stops on the fence body allow for fast angle set-up at 45-degree in and out, and a positive stop for perfect 90-degree angles. The parallelogram design keeps the table in close proximity to the cutterhead for improved finish and allows for a fast depth of cut adjustment. This design also ensures the tables remain perfectly parallel even after years of tough duty. The specially designed solid steel helical cutterhead consists of six rows of precision ground staggered inserts. This system makes fast work of knife changing and never needs adjustment. The heavy-duty 7-1/2 HP motor delivers all the power you need for even the biggest jobs. -

Out of stock

- Motor HP: 10 HP

- Phase: 3

- Voltage: 220V

- Amps: 28 Amps

- Hertz: 60

- Plug: No

- RPM: 3450

- Main Motor Switch: Radio Frequency

- Control Panel: Anodized Aluminum

- Hand Held Remote Control: HF (High Frequency)

- LED Warning Light Empty Drum: Yes

- Canister Auto Clean controlled by Timer: Yes

- Shop Setting CFM: 4700

- Inlet CFM: 8070

- Max Static Pressure (inches of water): 11″

- Impeller/Fan Size: 15.5″

-

Out of stock

The new TS29 Tilt/Slide Shaper is ready to tackle any job. A new fence design includes dual digital readouts, micrometer adjustments and independently adjustable fence halves for fast, accurate set-ups. The full guard includes two stock hold-downs and a see-through cover that flips up for quick tool changes. Dual dust collection ports, in the guard and under the table insure a clear work area and improved finish. An extra large quill assembly with a full seven inch stroke has three oversize bearings and the ability to tilt, adding versatility and insuring long, trouble-free performance. Powered by a big 7-1/2HP motor that drives the spindle forward and reverse with five speeds. The massive sliding table is fully supported by six tapered precision bearings through a full four-foot stroke. In addition, on board the table is a large miter head complete with stock hold-down clamp and a 56" miter fence with flip stop. The large table can easily accommodate a stock feeder for longer production runs.

The new TS29 Tilt/Slide Shaper is ready to tackle any job. A new fence design includes dual digital readouts, micrometer adjustments and independently adjustable fence halves for fast, accurate set-ups. The full guard includes two stock hold-downs and a see-through cover that flips up for quick tool changes. Dual dust collection ports, in the guard and under the table insure a clear work area and improved finish. An extra large quill assembly with a full seven inch stroke has three oversize bearings and the ability to tilt, adding versatility and insuring long, trouble-free performance. Powered by a big 7-1/2HP motor that drives the spindle forward and reverse with five speeds. The massive sliding table is fully supported by six tapered precision bearings through a full four-foot stroke. In addition, on board the table is a large miter head complete with stock hold-down clamp and a 56" miter fence with flip stop. The large table can easily accommodate a stock feeder for longer production runs. -

Out of stock

The JET JTM-4VS Mill is a variable speed vertical milling machine that is engineered to provide precision and reliability. MEEHANITE® castings, a heavy-duty splined motor and three-stage power downfeed with automatic stop are a few of the features loaded onto this JET mill. JET mills deliver performance and precision and are backed by an industry leading 2-year warranty.

The JET JTM-4VS Mill is a variable speed vertical milling machine that is engineered to provide precision and reliability. MEEHANITE® castings, a heavy-duty splined motor and three-stage power downfeed with automatic stop are a few of the features loaded onto this JET mill. JET mills deliver performance and precision and are backed by an industry leading 2-year warranty. -

Ironworker Max Force (Tons) 50 Oil Capacity (Gal.) 7 Speed (Strokes/Minute) 23 Throat Depth (In.) 7-1/2 5 Motor HP Hydraulic Pressure (PSI) 2500 Voltage 230 1 Phase 23 Amps Punching Station Pedestal Die Table Flat Bar Shear Angle Shear Universal Open Tooling Station Metalworking

Ironworker Max Force (Tons) 50 Oil Capacity (Gal.) 7 Speed (Strokes/Minute) 23 Throat Depth (In.) 7-1/2 5 Motor HP Hydraulic Pressure (PSI) 2500 Voltage 230 1 Phase 23 Amps Punching Station Pedestal Die Table Flat Bar Shear Angle Shear Universal Open Tooling Station Metalworking -

Out of stock

- Wide assortment of finger widths allow greater versatility in the shop

- With fingers installed it can be used as a full-length nose bar, turning the Machine into a straight bending brake

- All body sections are welded Steel plate with heavy truss rods and braces designed to give greater strength and durability

- Both the bed and apron are bored in line to assure the utmost accuracy

- Counter weights can be moved up or down to adjust desired leverage

-

Door builders and cabinet shops will love the extra capacity of this 37" wide-belt sander. Available with 15 HP 3-phase sanding motors, these wide-belts are built for daily industrial use with features such as a heavy-duty steel cabinet, pneumatic belt oscillation, and a built-in air filter/regulator. The digital control pad automates table adjustments and is accurate to 0.005". Also, the variable-speed conveyor, adjustable oscillation controls, and adjustable graphite/felt platen easily allow the operator to find the perfect combination of settings to achieve soft, smooth finishes on all types of wood.

Door builders and cabinet shops will love the extra capacity of this 37" wide-belt sander. Available with 15 HP 3-phase sanding motors, these wide-belts are built for daily industrial use with features such as a heavy-duty steel cabinet, pneumatic belt oscillation, and a built-in air filter/regulator. The digital control pad automates table adjustments and is accurate to 0.005". Also, the variable-speed conveyor, adjustable oscillation controls, and adjustable graphite/felt platen easily allow the operator to find the perfect combination of settings to achieve soft, smooth finishes on all types of wood.