-

Out of stock

The SIMPSON trailer pressure washer 3200 PSI at 2.8 GPM is a self-contained cleaning machine. Engineered to utilize the power and performance from top of the line SIMPSON pressure washers matched with the portability of a utility trailer. The 95000 is run by a Honda engine and comes with a 50’ hose, an ergonomic spray gun and 5 Quick-Connect nozzles. This mobile system brings a cleaning solution into the field where water supply is an issue. This powerful SIMPSON mobile pressure washing system will handle all your commercial jobs. It is perfectly suited for contract cleaners, mobile detailers, municipalities and resorts. The trailer is dot certified as an over-the-road pressure washer system. Job-Site set-up is a snap. Pull up to the work area, connect the spray gun, start the engine and begin cleaning. Warranty Details: Engine - 3 Year Limited Commercial Warranty | Pump - 5 Year Limited Warranty | Frame - 1 Year Limited Warranty

The SIMPSON trailer pressure washer 3200 PSI at 2.8 GPM is a self-contained cleaning machine. Engineered to utilize the power and performance from top of the line SIMPSON pressure washers matched with the portability of a utility trailer. The 95000 is run by a Honda engine and comes with a 50’ hose, an ergonomic spray gun and 5 Quick-Connect nozzles. This mobile system brings a cleaning solution into the field where water supply is an issue. This powerful SIMPSON mobile pressure washing system will handle all your commercial jobs. It is perfectly suited for contract cleaners, mobile detailers, municipalities and resorts. The trailer is dot certified as an over-the-road pressure washer system. Job-Site set-up is a snap. Pull up to the work area, connect the spray gun, start the engine and begin cleaning. Warranty Details: Engine - 3 Year Limited Commercial Warranty | Pump - 5 Year Limited Warranty | Frame - 1 Year Limited Warranty -

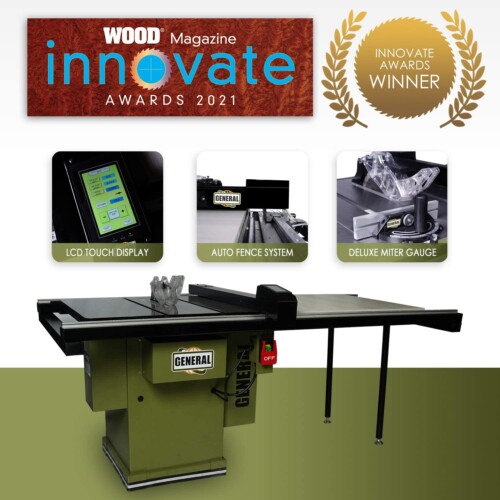

- PROGRAMABLE 10-INCH TABLE SAW: Digital and programmable auto-adjusting table saw with a 52-inch rip capacity makes your days work ripping down material quick and easy

- AUTOMATIC BLADE ANGLE ADJUSTMENT: Motorized blade angle adjustment allows you to adjust the angle of your cut quickly and easily through the digital keypad

- AUTOMATIC RIP FENCE ADJUSTMENT: Motorized rip fence allows you to adjust the dimension of your cut quickly and easily through the digital keypad

- DURABLE AND SMOOTH TABLE SURFACE: Heavy-duty, flat, polished cast iron table surface gives you seamless ripping performance as there is nothing for your material to get snagged on

- DUST-FREE MOTOR ENCLOSURE WITH FAN: Totally enclosed fan-cooled motor gives you long-lasting performance with no hiccups and no need to clean the motor of dust

-

Out of stock

-

Out of stock

-

Out of stock

The Powermatic 3520B Woodworking Lathe retains all the features of classic Powermatic lathes--including a sliding headstock, electronic variable-speed control, and a spindle lock--plus some great innovations. A digital RPM readout makes it a snap to keep track of your speed, a redesigned tailstock offers internal storage, and a laser etched quill conveniently self ejects. With the 3520B, you'll get classic reliability and advanced technology--the best of both worlds to help you handle your most important jobs. Features:

The Powermatic 3520B Woodworking Lathe retains all the features of classic Powermatic lathes--including a sliding headstock, electronic variable-speed control, and a spindle lock--plus some great innovations. A digital RPM readout makes it a snap to keep track of your speed, a redesigned tailstock offers internal storage, and a laser etched quill conveniently self ejects. With the 3520B, you'll get classic reliability and advanced technology--the best of both worlds to help you handle your most important jobs. Features:- Sliding headstock with electronic variable speed and digital RPM readout

- Two-position mount for the optional bed extension

- Spindle lock and built-in spindle indexing on the headstock

- Tool rest assembly with improved locking on a new profile tool rest

- Set of dead centers which hold a spindle for visual comparison

- Optional dust assembly that travels with the tool rest

- Laser etched quill which is self-ejecting

- Sliding hammer knockout rod with brass tip

- Attached tool caddy for tool storage

- Tailstock with internal storage

- Chrome trimmed hand-wheels

-

Out of stock

Finally, a production class Dual Drum Sander that is loaded with features. This machine features a 5HP motor to power the twin poly V-belts. The dual steel drums have a hard durometer rubber coating to assure a flat, mar free finish. Independently adjustable rear drum makes fine tuning easy. A heavy cast iron table incorporates four solid jackscrews with chain drive timing to keep it level at all times. The heavy-duty poly conveyor belt provides a positive grip on the stock. The 1/4HP feed motor is coupled to a two-speed forward/reverse gearbox that will sand 8 and 12 surface feet per minute. The heavy steel cabinet provides years of vibration free sanding, with plenty of storage space underneath.

Finally, a production class Dual Drum Sander that is loaded with features. This machine features a 5HP motor to power the twin poly V-belts. The dual steel drums have a hard durometer rubber coating to assure a flat, mar free finish. Independently adjustable rear drum makes fine tuning easy. A heavy cast iron table incorporates four solid jackscrews with chain drive timing to keep it level at all times. The heavy-duty poly conveyor belt provides a positive grip on the stock. The 1/4HP feed motor is coupled to a two-speed forward/reverse gearbox that will sand 8 and 12 surface feet per minute. The heavy steel cabinet provides years of vibration free sanding, with plenty of storage space underneath. -

Out of stock

The Byrd cutterhead is so effective because its 99 carbide inserts are arranged in spiral-shaped rows, have a four-inch radius ground into them, and are mounted so that they approach the wood at a 14-degree angle. The result is a true shear cut that dramatically reduces impact and the resulting fiber disturbance other cutterhead designs deliver. The 209HH is also very quiet during operation. The 209HH is built to last, with a solid cast-iron base, table, and head, and a precision-ground and polished cast-iron, 20- x 25-1/2-inch (W x D) table that rides on four steel columns--plenty of support for large workpieces. And heavy, cast-iron extension wings ensure a flat, smooth cut. To help maintain a cleaner, healthier work environment, there's a five-inch dust port that connects easily to any dust collector. [fusion_checklist icon="check" iconcolor="#aaaaaa" circle="no"]

The Byrd cutterhead is so effective because its 99 carbide inserts are arranged in spiral-shaped rows, have a four-inch radius ground into them, and are mounted so that they approach the wood at a 14-degree angle. The result is a true shear cut that dramatically reduces impact and the resulting fiber disturbance other cutterhead designs deliver. The 209HH is also very quiet during operation. The 209HH is built to last, with a solid cast-iron base, table, and head, and a precision-ground and polished cast-iron, 20- x 25-1/2-inch (W x D) table that rides on four steel columns--plenty of support for large workpieces. And heavy, cast-iron extension wings ensure a flat, smooth cut. To help maintain a cleaner, healthier work environment, there's a five-inch dust port that connects easily to any dust collector. [fusion_checklist icon="check" iconcolor="#aaaaaa" circle="no"]- one dust hood

- two cast-iron extension tables

- one handwheel

- one handle

- one low-speed gear kit

- two hardware bags

- one owner's manual

- warranty card

-

Out of stock

The award winning PM2000B table saw sets a new standard for innovation with an array of patented features and massive body design. The cast iron tables are oversized, and the newly designed arbor lock lever is accessible from above the table top to eliminate the need for dual arbor wrenches. The quick-release riving knife design helps reduce the chance of kickback. The blade tilt scale features an integrated digital read out as well as adjustable angle indicators for repetitive bevel cuts. The newly designed integrated retractable hydraulic caster system mobilizes your table saw much higher than the previous model to assist when moving over thresholds. A wide stance, heavy-duty box trunnion and concave teeth on the trunnion gears promote easier raising and tilting of saw blade. Poly-V drive belt system results in quieter, more efficient power transfer from the motor to the arbor with virtually no vibration and less heat build-up. Improved built-in dust collection port with convenient access to the inside of the saw cabinet for simple clean-up. The saw has a proprietary safety switch with magnetic interlock and the stop button can be knee activated.

The award winning PM2000B table saw sets a new standard for innovation with an array of patented features and massive body design. The cast iron tables are oversized, and the newly designed arbor lock lever is accessible from above the table top to eliminate the need for dual arbor wrenches. The quick-release riving knife design helps reduce the chance of kickback. The blade tilt scale features an integrated digital read out as well as adjustable angle indicators for repetitive bevel cuts. The newly designed integrated retractable hydraulic caster system mobilizes your table saw much higher than the previous model to assist when moving over thresholds. A wide stance, heavy-duty box trunnion and concave teeth on the trunnion gears promote easier raising and tilting of saw blade. Poly-V drive belt system results in quieter, more efficient power transfer from the motor to the arbor with virtually no vibration and less heat build-up. Improved built-in dust collection port with convenient access to the inside of the saw cabinet for simple clean-up. The saw has a proprietary safety switch with magnetic interlock and the stop button can be knee activated. -

Out of stock

The PM2000 table saw sets a new standard for innovation with an array of patented features and massive body design. It boasts the heaviest cast iron base in its class that virtually eliminates table vibration. The cast iron tables are oversized, and the push button arbor lock is accessible from above the table top to eliminate the need for dual arbor wrenches. The quick-release riving knife design helps reduce the chance of kickback. The blade tilt scale has adjustable angle indicators for repetitive bevel cuts. Built-in retractable omni-directional caster system mobilizes your table saw. A wide stance, heavy-duty trunnion and concave teeth on the trunnion gears promote easier raising and tilting of saw blade. Poly-V drive belt system results in quieter, more efficient power transfer from the motor to the arbor with virtually no vibration and less heat build up. Built-in dust collection port with sloped cabinet floor and convenient access to the inside of the saw cabinet make for simple clean-up. The saw has a proprietary safety switch with magnetic interlock, and the stop button can be knee activated.

The PM2000 table saw sets a new standard for innovation with an array of patented features and massive body design. It boasts the heaviest cast iron base in its class that virtually eliminates table vibration. The cast iron tables are oversized, and the push button arbor lock is accessible from above the table top to eliminate the need for dual arbor wrenches. The quick-release riving knife design helps reduce the chance of kickback. The blade tilt scale has adjustable angle indicators for repetitive bevel cuts. Built-in retractable omni-directional caster system mobilizes your table saw. A wide stance, heavy-duty trunnion and concave teeth on the trunnion gears promote easier raising and tilting of saw blade. Poly-V drive belt system results in quieter, more efficient power transfer from the motor to the arbor with virtually no vibration and less heat build up. Built-in dust collection port with sloped cabinet floor and convenient access to the inside of the saw cabinet make for simple clean-up. The saw has a proprietary safety switch with magnetic interlock, and the stop button can be knee activated. -

Out of stock

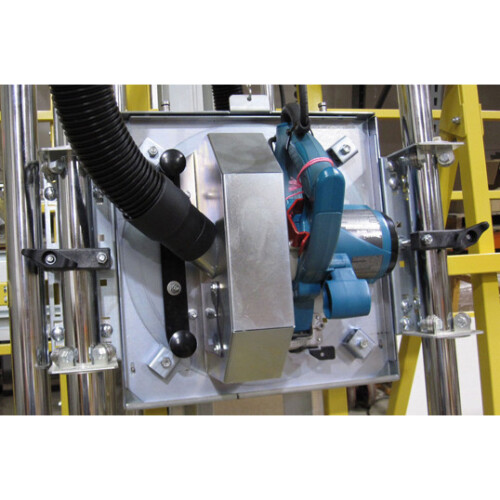

Sign Shops cut a variety of material, not just wood, materials such as aluminum composites, corrugated plastics, foam board, PVC material, wood and much more. For some time, sign shops had to use different machines to cut each material. Thankfully, those days are gone, with the help of our Sign Maker’s Series. FS100SM model features a 120" wide frame and a 100" vertical cut. [fusion_checklist icon="check" iconcolor="#aaaaaa" circle="no"]

Sign Shops cut a variety of material, not just wood, materials such as aluminum composites, corrugated plastics, foam board, PVC material, wood and much more. For some time, sign shops had to use different machines to cut each material. Thankfully, those days are gone, with the help of our Sign Maker’s Series. FS100SM model features a 120" wide frame and a 100" vertical cut. [fusion_checklist icon="check" iconcolor="#aaaaaa" circle="no"]- Full Size 120" Wide Frame

- Makita 5007F 7.25" saw

- Spinning saw insert plate

- Spring Hold Down

- Pivoting Knife Cutter

- Dust hood, hose, brush

- Folding Stand and Wheels

- Dual Rip Gauge

- Stop, Bar and Tapes

- Patented Accu-Square System

- Sealed Steel Bearings

-

Out of stock

Solid design and construction deliver precision operation and control. JET 20” Variable Speed Drill Presses combine variable speed spindles with a massively constructed head that increases accuracy and rigidity. That’s all on top of a steel column and a heavy-duty cast iron base.

Solid design and construction deliver precision operation and control. JET 20” Variable Speed Drill Presses combine variable speed spindles with a massively constructed head that increases accuracy and rigidity. That’s all on top of a steel column and a heavy-duty cast iron base.