New model includes: Sanding Head Assembly with Flatter Installed, Conveyor Table Assembly, An Aluminum Drum w/ Two Bearing Sets, A Coupling and one 80 Girt Abrasive Belt, Open Stand Assembly.

Drum sanding with Intellisand technology.

- Eliminates the guess-work of manually controlling the infinitely-variable feed speed

- Simplifies the sanding operation

- Provides a consistent finish even with varying grain pattern and density

- Greatly increases abrasive planning and dimensioning speed

- Maintains highest possible feed rate without overload

19-38” Combo Drum/Brush Sander

- True combo machine: Drum and Flat stock. Change sanding heads and sand contoured shapes

- Brush Applications include but are not limited to: white wood sanding, de-nibbing, sealer sanding, primer sanding, UV roughing, metal graining/straight lining, metal de-burring, sanding/polishing solid surface material, scuff sanding, shutter sanding, de-glossing and distressing

- Bench-top unit, standard with 180 Grit Flatter sanding head

- AC Inverter – Variable Head Speed, 200-1800 RPM

- Tension rollers are adjustable in height, span, and hold down pressure

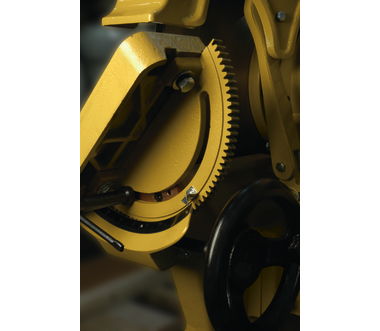

- Heavy-duty cast iron construction for strength, rigidity, and reduced vibration

- Preset “fast” control to adjust for 38” use

Download Manual

Specifications:

Warranty: Two years on parts and labor, limited; Manufacturer’s warranties on conveyor belts, brush heads and abrasives.

Sanding Capacity:

Maximum Width: 38” (two passes)

Minimum Length: 2-1/4” to 3-1/2” (varies with application)

Maximum Thickness: 4” typical (varies with brush/drum style & application)

Minimum Thickness: 1/32” typical (varies with applications)

Dimensions:

Length – 36”

Width – 42”

Height – 24” without stand

Brush: 5” diameter typical

Typical bristle length: 1-1/2” (varies)

Brush Speed:

Infinitely variable 200 to 1000 RPM

Brush 1750 RPM

Drum Dust Hood: Hinged back with 4” vacuum port

Height Adjustment: 1/16” per revolution, Depth Gauge included Conveyor

Motor: 43”–lb. torque Direct drive D.C. motor Infinitely variable 0–10 feet-per-minute

Drive Motor (TEFC): 1-3/4 HP Continuous-duty

Power Requirements: 110 Volt, Single Phase 20 amp service

Shipping Weight: 242lbs. (weight varies on how equipped) 2 boxes