-

Out of stock

-

Out of stock

-

Out of stock

These JET Drill Presses use a variable-speed motor with the stepped-pulley system, and come equipped with a continuously variable transmission. This enables use at a wide range of speeds, as well as the ability to change speed during operation. A scale-marked hand wheel that matches the desired machine speed is mounted to a reduction gearing system for precise operator control. This adjusts the gearing ratio between the motor's fixed pulley and the output shaft's variable pulley, changing the speed of the chuck. A tensioner pulley is implemented in the belt transmission to take up or release the slack in the belt as the speed changes.

These JET Drill Presses use a variable-speed motor with the stepped-pulley system, and come equipped with a continuously variable transmission. This enables use at a wide range of speeds, as well as the ability to change speed during operation. A scale-marked hand wheel that matches the desired machine speed is mounted to a reduction gearing system for precise operator control. This adjusts the gearing ratio between the motor's fixed pulley and the output shaft's variable pulley, changing the speed of the chuck. A tensioner pulley is implemented in the belt transmission to take up or release the slack in the belt as the speed changes. -

Out of stock

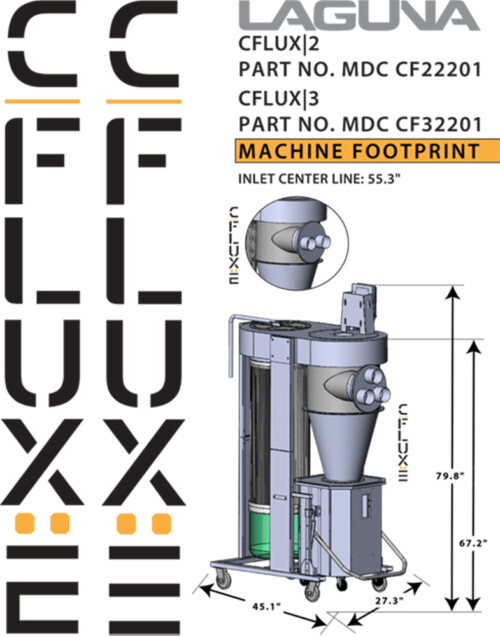

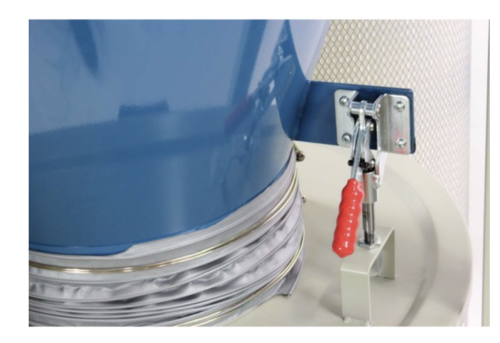

The c|flux series sets a new standard for cyclones. The horizontal chute is designed to maximize airflow while improving CFM. All shapes and dimensions has been reevaluated to optimize performance. The c|flux:3 comes standard with a 1 micron canister providing filtration of 99.7% of particles 1 micron or larger & features 109 sq/ft. of polyester spun bond pleated filter to ensure maximum airflow. 270° manual clean comes standard. The c|flux series can be equipped with an optional auto clean kit either at time of purchase or as an add-on later. The auto clean kit includes a smart sensor that detects a drop in air pressure indicating the filter is getting clogged and automatically activates the cleaning procedure. Ingenious lift system quickly moves the drum off the floor and seals against the drum lid, avoiding the need for a flex hose. This design allows for much better portability as you are not forcing 4 wheels into the floor while pushing the unit.

The c|flux series sets a new standard for cyclones. The horizontal chute is designed to maximize airflow while improving CFM. All shapes and dimensions has been reevaluated to optimize performance. The c|flux:3 comes standard with a 1 micron canister providing filtration of 99.7% of particles 1 micron or larger & features 109 sq/ft. of polyester spun bond pleated filter to ensure maximum airflow. 270° manual clean comes standard. The c|flux series can be equipped with an optional auto clean kit either at time of purchase or as an add-on later. The auto clean kit includes a smart sensor that detects a drop in air pressure indicating the filter is getting clogged and automatically activates the cleaning procedure. Ingenious lift system quickly moves the drum off the floor and seals against the drum lid, avoiding the need for a flex hose. This design allows for much better portability as you are not forcing 4 wheels into the floor while pushing the unit. -

Out of stock

SUPMX-72550 25-50 Drum Sander with Closed Stand, w/ built in casters, 110V, 1-3/4HP The 25-50 Drum Sander is the newest member of SuperMax Tools drum sander family which was designed with new features to improve productivity. Patented Quick Adjustment Lever: reduces set-up time. Turbo Vented dust port: increases airflow to your dust collector by 15%. Rear placement of the Gear Motor: improve conveyor belt tracking. These new features complement the same great features SuperMax Tools have provided for years. Patented Fast Lever: allows quick adjustments for wide and narrow stock INTELLISAND Technology: prevents gouging, damaging, or burning material. The SuperMax 25-50 Drum Sander is the largest open-ended drum sander on the market. Sand 25″ in a single pass, and up to 50” in a double pass. Features:

SUPMX-72550 25-50 Drum Sander with Closed Stand, w/ built in casters, 110V, 1-3/4HP The 25-50 Drum Sander is the newest member of SuperMax Tools drum sander family which was designed with new features to improve productivity. Patented Quick Adjustment Lever: reduces set-up time. Turbo Vented dust port: increases airflow to your dust collector by 15%. Rear placement of the Gear Motor: improve conveyor belt tracking. These new features complement the same great features SuperMax Tools have provided for years. Patented Fast Lever: allows quick adjustments for wide and narrow stock INTELLISAND Technology: prevents gouging, damaging, or burning material. The SuperMax 25-50 Drum Sander is the largest open-ended drum sander on the market. Sand 25″ in a single pass, and up to 50” in a double pass. Features:- Simple alignment feature Just one nut will adjust the conveyor to parallel the sanding head, making aligning the conveyor to the sanding head fast and easy.

- Indexed alignment setting Has an indexed alignment setting for narrow and wide stock. When sanding stock wider than 25”, the index lever will properly adjust the conveyor for flawless wide sanding.

- Easy height adjustments A thrust bearing below the handle and a nut positioned above prevents the drum from moving out of the set position while sanding. No backlash or slop in the height adjustment mechanism allowing easier and smoother height adjustments.

- Drum will never go “out of alignment” The drum carriage is bolted to the base, preventing any movement or alignment issues.

- INTELLISAND™ Technology: Automatically adjusts conveyor speed based on load

- Prevents gouging, damaging or burning stock

- Provides consistent finish even with varying grain pattern and density

- Greatly increases abrasive planing and dimensioning speed

- Flatness Guarantee: Precision-flattened steel conveyor bed reinforced with four steel cross sections for no “flex” in conveyor, guaranteeing flatness to less than .010″ across the width of the sander

- Abrasive conveyor belt offers the best grip for raw wood, giving you the ability to accommodate stock that is much shorter or thinner

- Patented Abrasive Attachment System effectively tensions the abrasive wraps, preventing loose abrasive and overlap

- Easiest access to abrasive fastening system of any drum sander! Extra wide space to access fasteners to eliminate need for special tools.

- Self-cooling drum prevents overheating and extends abrasive life

- Tension rollers are adjustable in height and hold down pressure, eliminating snipe

- Excellent dust extraction as dust cover is formed to shape of drum

- Metal, not plastic, is formed to maximize air flow and dust extraction

- Heavy-duty cast iron construction for strength, rigidity and reduced vibration

- Mobile Base allows for stand and machine to be to moved easily

- Optional Accessory Available: DRO (digital read out): maintain material thicknesses to increase accuracy and quality.

Sanding Capacity: Maximum Width (in): 50 (two passes) Minimum Length (in): 2-1/4 Maximum Thickness (in): 4 Minimum Thickness (in): 1/32 Dimensions (in): 27D x 46W x 53H (on stand) Drum: 5 x 25 extruded aluminum Drum Speed: 1740 RPM Dust Hood: 1- 4″ vacuum port, min. 600 CFM recommended Conveyor Motor: 43 in.-lb. torque, direct drive D.C. motor, ranged variable 0-10 FPM Drive Motor (TEFC): 1-3/4 HP Power Requirements 110 V 20 amp Shipping Weight (lbs): 369 (3 boxes incl. stand) -

Sale!

Out of stock

We took our new G1023RL table saw with riving knife and made it even better by including a built-in router table that doubles as a table extension wing. The router table includes support legs and universal T-track router clamping system, and the Shop Fox® Classic Fence included for the table saw doubles as a router table fence. You'll find that using this system is actually much nicer and more convenient than using a typical router table or hand held router for those cuts where the fence is not required to be offset, especially if the table saw is set up with large outfeed tables. Another great advantage is being able to make laser straight dadoes without having to change table saw blades. Please note: this router table does not work with small trim routers. CSA certified meeting CSA C22.2 #71.2-08 and UL 987 standards! SPECIFICATIONS:

We took our new G1023RL table saw with riving knife and made it even better by including a built-in router table that doubles as a table extension wing. The router table includes support legs and universal T-track router clamping system, and the Shop Fox® Classic Fence included for the table saw doubles as a router table fence. You'll find that using this system is actually much nicer and more convenient than using a typical router table or hand held router for those cuts where the fence is not required to be offset, especially if the table saw is set up with large outfeed tables. Another great advantage is being able to make laser straight dadoes without having to change table saw blades. Please note: this router table does not work with small trim routers. CSA certified meeting CSA C22.2 #71.2-08 and UL 987 standards! SPECIFICATIONS:- Motor: 3 HP, 240V, single-phase, 14A

- Rip capacity: 8" left, 32" right of blade

- Maximum depth of cut @ 90°: 3"

- Maximum depth of cut @ 45°: 2-1/8"

- Assembled table size: 48" W x 27" D

- Distance from front of table to center of blade: 17"

- Floor-to-table height: 34"

- Arbor diameter: 5/8"

- Arbor speed: 4200 RPM

- Max. width of dado: 13/16"

- Overall dimensions: 66" W x 47" D x 39-3/4" H

- Footprint: 20-1/2" x 20-1/2"

- Approximate shipping weight: 550 lbs.

- Built-in cast-iron router table extension with adjustable legs

- Precision-ground cast-iron table

- 4" Dust port

- Extra large handwheels ease arbor movement

- Quickly changes between riving knife and blade guard

- Magnetic safety switch is standard

- One-piece steel cabinet type stand

- All sealed ball-bearing construction

- Poly-V serpentine belt transfers power more efficiently and with less noise than standard V-belts

- Underside of blade encapsulated for superior dust collection

- Certified to UL & CSA standards

- Includes 10" x 40T blade!

-

-

Out of stock

Designed to perform, the JET 15” bandsaw delivers more re-saw capacity, greater throat depth and the horsepower you need to tackle bigger boards, create smoother edges and master the intricate cuts. The heavy-duty cast-iron fence system is built to give you the sturdiness and support you need for every project and features a micro-adjust dial for exact placement. The table is slotted and the guide post has a stress-free magnetic door on the front for efficient blade changes. Large, independently adjustable guides are tool-less to save you time on set up. The JET 15” steel frame bandsaw is engineered to build great projects through superior performance.

Designed to perform, the JET 15” bandsaw delivers more re-saw capacity, greater throat depth and the horsepower you need to tackle bigger boards, create smoother edges and master the intricate cuts. The heavy-duty cast-iron fence system is built to give you the sturdiness and support you need for every project and features a micro-adjust dial for exact placement. The table is slotted and the guide post has a stress-free magnetic door on the front for efficient blade changes. Large, independently adjustable guides are tool-less to save you time on set up. The JET 15” steel frame bandsaw is engineered to build great projects through superior performance. -

All-new for 2021, the Laguna JX|8 QuadTec I is loaded with highly desirable features to make jointing safer and more enjoyable. The JX|8 is available in 2 versions. This version is the 110 Volt 1.75 HP version. JX|8 Quadtec I Standard Features:

All-new for 2021, the Laguna JX|8 QuadTec I is loaded with highly desirable features to make jointing safer and more enjoyable. The JX|8 is available in 2 versions. This version is the 110 Volt 1.75 HP version. JX|8 Quadtec I Standard Features:- Parallelogram Table Adjustments - Table depth adjustments travel along an arc to keep the same distance to the cutterhead through its travel

- Emergency “Knee-Stop” - The new knee stop uses a body-length bar at knee height to shut off the JX jointer. This important safety feature allows the machine operator to stop the machine quickly at any position along the front of the machine while keeping hands on the workpiece

- New Ergonomic Machine Body - The new JX Series machine body has been redesigned with a “toe-kick” to allow the user to position themself closer to the machine tables and to move safer and easier along the length of the machine

- In-feed Support Roller - Infeed tables are now fitted with pull-out support roller to help support longer materials

- QuadTec I Cutterhead - The all-new QuadTec I cuttherhead comes as standard equipment on the new JX-8 QuadTec I jointer. The QuadTec I produces an amazing surface finish on all woods including difficult hardwoods. The QuadTec I uses 4-sided carbide insert knives that are quieter and much more durable compared to straight HSS knives. The 4-sided knives can be rotated for a new cutting edge without the need for a knife setting jig

- Built-In Wheels - No need to purchase a separate mobility kit

- Cast-Iron Tables and Fence

-

Out of stock

https://youtu.be/J6zaJp77T3A

https://youtu.be/J6zaJp77T3A