- Powermatic products carry a limited warranty which varies in duration based upon the product. (See chart below)

- Accessories carry a limited warranty of one year from the date of receipt.

- Consumable items are defined as expendable parts or accessories expected to become inoperable within a reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.Who is CoveredThis warranty covers only the initial purchaser of the product from the date of delivery.What is CoveredThis warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear, improper repair, alterations or lack of maintenance. Powermatic woodworking machinery is designed to be used with Wood. Use of these machines in the processing of metal, plastics, or other materials outside recommended guidelines may void the warranty. The exceptions are acrylics and other natural items that are made specifically for wood turning.Warranty LimitationsWoodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

-

Out of stock

Powermatic warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday. Warranty Period The general warranty lasts for the time period specified in the literature included with your product or on the official Powermatic branded website.

Powermatic warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair, please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday. Warranty Period The general warranty lasts for the time period specified in the literature included with your product or on the official Powermatic branded website. -

- Sealed and permanently lubricated drum ball bearings for longer life

- Oscillating feature reduces heat build-up on sanding belt to reduce loading and burning

- SandSmart™ infinitely variable-feed control produces the ultimate finish at a rate of up to 10 feet per minute

- Conveyor belt TRACKERS™ dramatically reduce the need for manual belt adjustments

- 1" of oscillating stroke

-

Out of stock

- Cabinet saw that only requires 115V power

- A blade surround and collection hose provide an unobstructed path, maximizing dust collection

- Conveniently located hands free power switch

- Tool-less guard assembly with independent side leaves is easy to use, maximizing safety

- The sturdy miter gauge pivots 60 degrees to either side, allowing easy adjustment for a full range of cuts

- HP 1.75

- Weight 465 lbs

- Product Dimensions 36 x 27.5 x 63.8"

- Voltage 115

-

DESCRIPTION

The C4 model packs all of the features of the full-size saws into a portable 5′ frame. This panel saw can travel to work sites and fit into shops with limited floor space. The C4 is ideal for cutting 4’–8′ sheets of material. Standard Equipment- 3 ¼ Hp, 15 amp industrial duty saw motor.

- Zinc plated 1 ¾” steel guide tubes.

- 4 Nylatron roller bearing systems.

- Adjustable vertical and horizontal rulers.

- Quick change from vertical to horizontal cutting.

- Thin material pressure guard.

- Injection-molded plastic material rollers.

- Spring loaded counter balance system.

- Integrated dust collection bonnet.

- Extended warranty.

- TUV certified to UL/CSA standards

- Wall mounted

- Wheels not included

- Dust Collection not included

-

DESCRIPTION

The C4 model packs all of the features of the full-size saws into a portable 5′ frame. This panel saw can travel to work sites and fit into shops with limited floor space. The C4 is ideal for cutting 4’–8′ sheets of material. Standard Equipment- 3 ¼ Hp, 15 amp industrial duty saw motor.

- Zinc plated 1 ¾” steel guide tubes.

- 4 Nylatron roller bearing systems.

- Adjustable vertical and horizontal rulers.

- Quick change from vertical to horizontal cutting.

- Thin material pressure guard.

- Injection-molded plastic material rollers.

- Spring loaded counter balance system.

- Integrated dust collection bonnet.

- Extended warranty.

- TUV certified to UL/CSA standards

- Wall mounted

- QUICK STOP™ Gauge 5 ft./2.44m

- Dust collection kit (vacuum additional)

- Fixed stand/folding stand with C-Series

- Set of wheels

- 860ATB Foam Core Saw Blade

-

The helical cutterhead delivers near mirror-smooth finishes right out of the gate. It consists of four rows of 52 indexable carbide inserts, each angled slightly to produce a shearing action. This shearing action results in less tearout in highly figured woods and quieter operation—and the planed surfaces are far superior to what you'll get with 15" straight-knife or other spiral cutterheads on the market. SPECIFICATIONS:

The helical cutterhead delivers near mirror-smooth finishes right out of the gate. It consists of four rows of 52 indexable carbide inserts, each angled slightly to produce a shearing action. This shearing action results in less tearout in highly figured woods and quieter operation—and the planed surfaces are far superior to what you'll get with 15" straight-knife or other spiral cutterheads on the market. SPECIFICATIONS:- Motor: 3 HP, 230V, single-phase, 12A

- Maximum stock width: 15"

- Maximum stock thickness: 6"

- Minimum stock thickness: 3/16"

- Minimum stock length: 6"

- Maximum cutting depth: 1/8"

- Cutterhead diameter: 3"

- Cutterhead type: 4-row helical with 52 inserts

- Cutterhead speed: 5000 RPM

- Insert size and type: 15 x 15 x 2.5mm, indexable carbide

- Feed rate: Variable, 10–28 FPM

- Table size with extensions: 15" x 48"

- Dust port size: 4"

- Footprint: 22-1/2" x 23"

- Overall dimensions: 39" W x 48" D x 44-1/2" H

- Approx. shipping weight: 595 lbs.

-

-

New model includes: Sanding Head Assembly with Flatter Installed, Conveyor Table Assembly, An Aluminum Drum w/ Two Bearing Sets, A Coupling and one 80 Girt Abrasive Belt, Open Stand Assembly.

Drum sanding with Intellisand technology.

- Eliminates the guess-work of manually controlling the infinitely-variable feed speed

- Simplifies the sanding operation

- Provides a consistent finish even with varying grain pattern and density

- Greatly increases abrasive planning and dimensioning speed

- Maintains highest possible feed rate without overload

19-38” Combo Drum/Brush Sander

- True combo machine: Drum and Flat stock. Change sanding heads and sand contoured shapes

- Brush Applications include but are not limited to: white wood sanding, de-nibbing, sealer sanding, primer sanding, UV roughing, metal graining/straight lining, metal de-burring, sanding/polishing solid surface material, scuff sanding, shutter sanding, de-glossing and distressing

- Bench-top unit, standard with 180 Grit Flatter sanding head

- AC Inverter – Variable Head Speed, 200-1800 RPM

- Tension rollers are adjustable in height, span, and hold down pressure

- Heavy-duty cast iron construction for strength, rigidity, and reduced vibration

- Preset “fast” control to adjust for 38” use

Download ManualSpecifications:

Warranty: Two years on parts and labor, limited; Manufacturer’s warranties on conveyor belts, brush heads and abrasives.

Sanding Capacity:

Maximum Width: 38” (two passes)

Minimum Length: 2-1/4” to 3-1/2” (varies with application)

Maximum Thickness: 4” typical (varies with brush/drum style & application)

Minimum Thickness: 1/32” typical (varies with applications)

Dimensions:

Length – 36”

Width – 42”

Height – 24” without stand

Brush: 5” diameter typical

Typical bristle length: 1-1/2” (varies)

Brush Speed:

Infinitely variable 200 to 1000 RPM

Brush 1750 RPM

Drum Dust Hood: Hinged back with 4” vacuum port

Height Adjustment: 1/16” per revolution, Depth Gauge included Conveyor

Motor: 43”–lb. torque Direct drive D.C. motor Infinitely variable 0–10 feet-per-minute

Drive Motor (TEFC): 1-3/4 HP Continuous-duty

Power Requirements: 110 Volt, Single Phase 20 amp service

Shipping Weight: 242lbs. (weight varies on how equipped) 2 boxes

-

-

Style (Type) Planer Cutterhead Speed (RPM) 4500 Cutterhead Diameter (In.) 2-7/8 Number of Knives 68 Four-Sided Inserts Maximum Full Width Depth of Cut (In.) 1/8 Maximum Planing Width (In.) 14-7/8 Maximum Planing Thickness (In.) 6 Minimum Planing Length (In.) 8 Feed Rate (FPM) 16, 20 Dust Collection Minimum CFM Required (CFM) 400 Dust Port Outside Diameter (In.) 4 Motor Power (HP) 3 Motor Phase (PH) 1 Motor Voltage (V.) 230 Prewired Voltage (V.) 230 Motor Amps 11

Style (Type) Planer Cutterhead Speed (RPM) 4500 Cutterhead Diameter (In.) 2-7/8 Number of Knives 68 Four-Sided Inserts Maximum Full Width Depth of Cut (In.) 1/8 Maximum Planing Width (In.) 14-7/8 Maximum Planing Thickness (In.) 6 Minimum Planing Length (In.) 8 Feed Rate (FPM) 16, 20 Dust Collection Minimum CFM Required (CFM) 400 Dust Port Outside Diameter (In.) 4 Motor Power (HP) 3 Motor Phase (PH) 1 Motor Voltage (V.) 230 Prewired Voltage (V.) 230 Motor Amps 11 -

Out of stock

Quiet, Compact, and Powerful - Ideal for Small Personal Workshops!

2019 Edition - New features for improved efficiency and ease of use! This system is ideal for use in small 1-2 man shops operating tools such as lathes, planers, radial/miter saws, and more! The V-System's molded static dissipative resin construction speeds up and simplifies system assembly, maximizes airflow performance, and significantly reduces noise levels. Learn how the V-System helped Kawneer North America improve their production workflows. Read the case study.Included Features & Components:

- Industrial 3HP 230V U.S. Made Motor (Only have 110V power?)

- Magnetic Starter w/ Overload Protector

- Wireless RF Remote Control Keyfob

- High-Efficiency Molded Cyclone Separator

- 3rd Party Tested HEPA Cartridge Filter

- Stacking Sound Filter & Drop-in Silencer

- Compact Steel Angle Frame Stand or Wall Mounting Bracket

- 35 or 55-Gallon Reinforced Steel Dust Bin

- Dust Sentry™ Bin Fill Level Indicator

- D.I.Y. Ductwork Design Guide

- 1 Year Limited Warranty

-

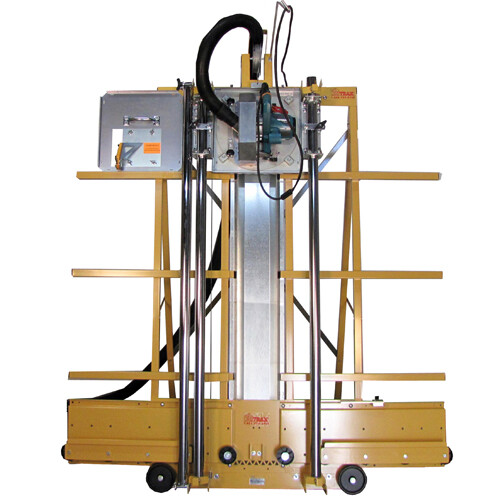

Sign Shops cut a variety of material, not just wood, materials such as aluminum composites, corrugated plastics, foam board, PVC material, wood and much more. For some time, sign shops had to use different machines to cut each material. Thankfully, those days are gone, with the help of our Sign Maker’s Series. C52SM model features a 60" wide frame for size restricted shops and a 52" vertical cut. Also available in Full Size models.

Sign Shops cut a variety of material, not just wood, materials such as aluminum composites, corrugated plastics, foam board, PVC material, wood and much more. For some time, sign shops had to use different machines to cut each material. Thankfully, those days are gone, with the help of our Sign Maker’s Series. C52SM model features a 60" wide frame for size restricted shops and a 52" vertical cut. Also available in Full Size models.- Compact 60" Wide Frame

- Makita 5007F 7.25" saw

- Spinning saw insert plate

- Spring Hold Down

- Pivoting Knife Cutter

- Dust hood, hose, brush

- Folding Stand and Wheels

- Dual Rip Gauge

- Stop, Bar and Tapes

- Patented Accu-Square System

- Sealed Steel Bearings

-

This Deluxe XACTASAW has a quick-release riving knife and integrated arbor lock that's more efficient and keeps the operator safe. This Deluxe XACTASAW model offers an upgraded Poly-V belt drive system for smooth operation and optimal power transfer, plus a fully shrouded blade for highly efficient dust collection.

This Deluxe XACTASAW has a quick-release riving knife and integrated arbor lock that's more efficient and keeps the operator safe. This Deluxe XACTASAW model offers an upgraded Poly-V belt drive system for smooth operation and optimal power transfer, plus a fully shrouded blade for highly efficient dust collection. -

DESCRIPTION

The C4 model packs all of the features of the full-size saws into a portable 5′ frame. This panel saw can travel to work sites and fit into shops with limited floor space. The C4 is ideal for cutting 4’–8′ sheets of material. Standard Equipment- 3 ¼ Hp, 15 amp industrial duty saw motor.

- Zinc plated 1 ¾” steel guide tubes.

- 4 Nylatron roller bearing systems.

- Adjustable vertical and horizontal rulers.

- Quick change from vertical to horizontal cutting.

- Thin material pressure guard.

- Injection-molded plastic material rollers.

- Spring loaded counter balance system.

- Integrated dust collection bonnet.

- Extended warranty.

- TUV certified to UL/CSA standards

- Wall mounted

- QUICK STOP™ Gauge 5 ft./2.44m

- Dust collection kit (vacuum additional)

- Fixed stand/folding stand with C-Series

- Set of wheels

- 860ATB Foam Core Saw Blade

- Folding stand

-

Out of stock

Integrated LED Control Panel shows power, belt speed, and DRO. Equipped with Feed Logic to produce exceptional finish while preventing machine overload. Secondary, absolute depth scale provides an additional height reading. Drum carriage is cast iron to provide greater strength and consistent performance. Steel hood with a 4 dust port provide excellent dust collection.

Integrated LED Control Panel shows power, belt speed, and DRO. Equipped with Feed Logic to produce exceptional finish while preventing machine overload. Secondary, absolute depth scale provides an additional height reading. Drum carriage is cast iron to provide greater strength and consistent performance. Steel hood with a 4 dust port provide excellent dust collection. -

- Triangular design provides superior column rigidity

- 12-1/4-Inch Resaw capacity for cutting large pieces of wood, slicing veneers and cutting book matched panels

- 21-Inch by 21-Inch precision ground cast iron table for added stability and work support

- 2 Speed poly V-belt drive

- Precision computer balanced wheels eliminate vibration for accurate blade tracking

-

Cutterhead Speed (RPM) 5000 Cutterhead Diameter (In.) 3-3/16 Number of Knives 4 Maximum Full Width Depth of Cut (In.) 3/32 Maximum Planing Width (In.) 20 Maximum Planing Thickness (In.) 8 Minimum Planing Length (In.) 6-3/4 Feed Rate (FPM) 24/31 Table Size (L x W) (In.) 25-3/4 x 20 Dust Collection Minimum CFM Required (CFM) 400 Dust Port Outside Diameter (In.) 5 Motor Power (HP) 3 Motor Phase (PH) 1 Motor Voltage (V.) 230 Prewired Voltage (V.) 230 Motor Amps 14

Cutterhead Speed (RPM) 5000 Cutterhead Diameter (In.) 3-3/16 Number of Knives 4 Maximum Full Width Depth of Cut (In.) 3/32 Maximum Planing Width (In.) 20 Maximum Planing Thickness (In.) 8 Minimum Planing Length (In.) 6-3/4 Feed Rate (FPM) 24/31 Table Size (L x W) (In.) 25-3/4 x 20 Dust Collection Minimum CFM Required (CFM) 400 Dust Port Outside Diameter (In.) 5 Motor Power (HP) 3 Motor Phase (PH) 1 Motor Voltage (V.) 230 Prewired Voltage (V.) 230 Motor Amps 14 -

Style (Type) Cabinet Blade Diameter (In.) 10 Arbor Diameter (In.) 5/8 Arbor Speed (RPM) 4300 Maximum Depth of Cut (In.) 3 Maximum Depth of Cut at 45 Degrees (In.) 2-1/8 Maximum Rip Left of Blade (In.) 13 Maximum Rip Right of Blade (In.) 30 Table in Front of Saw Blade at Maximum Depth of Cut (In.) 10 Maximum Diameter of Dado (In.) 8 Maximum Width of Dado (In.) 13/16 Table Type Cast Iron Table Size (L x W) (In.) 29 x 20

Style (Type) Cabinet Blade Diameter (In.) 10 Arbor Diameter (In.) 5/8 Arbor Speed (RPM) 4300 Maximum Depth of Cut (In.) 3 Maximum Depth of Cut at 45 Degrees (In.) 2-1/8 Maximum Rip Left of Blade (In.) 13 Maximum Rip Right of Blade (In.) 30 Table in Front of Saw Blade at Maximum Depth of Cut (In.) 10 Maximum Diameter of Dado (In.) 8 Maximum Width of Dado (In.) 13/16 Table Type Cast Iron Table Size (L x W) (In.) 29 x 20 -

Sign Shops cut a variety of material, not just wood, materials such as aluminum composites, corrugated plastics, foam board, PVC material, wood and much more. For some time, sign shops had to use different machines to cut each material. Thankfully, those days are gone, with the help of our Sign Maker’s Series. C64SM model features a 60" wide frame for size restricted shops and a 64" vertical cut. Also available in Full Size models.

Sign Shops cut a variety of material, not just wood, materials such as aluminum composites, corrugated plastics, foam board, PVC material, wood and much more. For some time, sign shops had to use different machines to cut each material. Thankfully, those days are gone, with the help of our Sign Maker’s Series. C64SM model features a 60" wide frame for size restricted shops and a 64" vertical cut. Also available in Full Size models.- Compact 60" Wide Frame

- Makita 5007F 7.25" saw

- Spinning saw insert plate

- Spring Hold Down

- Pivoting Knife Cutter

- Dust hood, hose, brush

- Folding Stand and Wheels

- Dual Rip Gauge

- Stop, Bar and Tapes

- Patented Accu-Square System

- Sealed Steel Bearings

-

Out of stock

The Saw Trax Compact Varsity features big machine cutting capabilities in a smaller size frame. Compact frames are perfect for space restricted shops or for taking to the job site. The Varsity Series panel saw is a compact unit that includes standard features plus an accessory package recommended to most woodworkers. Ideal for customers who need to break down 5 foot sheet goods that are less than 1 3/4in. thick with precision cuts. A Makita 5007N circular saw and the best dust collection hook ups possible are provided with this machine. U.S.A.What's Included

The Saw Trax Compact Varsity features big machine cutting capabilities in a smaller size frame. Compact frames are perfect for space restricted shops or for taking to the job site. The Varsity Series panel saw is a compact unit that includes standard features plus an accessory package recommended to most woodworkers. Ideal for customers who need to break down 5 foot sheet goods that are less than 1 3/4in. thick with precision cuts. A Makita 5007N circular saw and the best dust collection hook ups possible are provided with this machine. U.S.A.What's Included -

Out of stock

The Saw Trax Full Size 1000 Series panel saw features a 120 inch wide frame and easily performs both vertical and horizontal cuts in your material. The 1052 features a 52″ vertical cut. This series includes an accessory package recommended for most general wood workers. This 1000 series are ideal for customers that need a vertical panel saw to perform precision cuts in sheet goods that are less than 1 ¾ inches thick.

The Saw Trax Full Size 1000 Series panel saw features a 120 inch wide frame and easily performs both vertical and horizontal cuts in your material. The 1052 features a 52″ vertical cut. This series includes an accessory package recommended for most general wood workers. This 1000 series are ideal for customers that need a vertical panel saw to perform precision cuts in sheet goods that are less than 1 ¾ inches thick.- Full Size 120" Wide Frame

- Makita 5007F 7.25" saw

- Spinning saw insert plate

- Dust hood, hose, brush

- Folding Stand and Wheels

- Dual Rip Gauge

- Stop, Bar and Tapes

- Patented Accu-Square System

- Sealed Steel Bearings

-

Out of stock

The 18” Bandsaw #10-347 has one of the most powerful motors in the line, 4HP with 19″ of re-saw capacity, which makes it ideal for woodworkers doing a lot of heavy re-saw work. Professional features include patient pending spring loaded tool-less guide system, massive cast iron table with quick adjust trunnion system, substantial quick adjust 6” tall rip fence system, key activated safety on/off switch, micro safety on/off switch activated door & foot brake. Under the top door blade tension release levers with blade tension hand wheel are easy to access from the front of the saw.

The 18” Bandsaw #10-347 has one of the most powerful motors in the line, 4HP with 19″ of re-saw capacity, which makes it ideal for woodworkers doing a lot of heavy re-saw work. Professional features include patient pending spring loaded tool-less guide system, massive cast iron table with quick adjust trunnion system, substantial quick adjust 6” tall rip fence system, key activated safety on/off switch, micro safety on/off switch activated door & foot brake. Under the top door blade tension release levers with blade tension hand wheel are easy to access from the front of the saw. -

Out of stock

-

Style (Type) Cabinet Blade Diameter (In.) 10 Arbor Diameter (In.) 5/8 Arbor Speed (RPM) 4300 Maximum Depth of Cut (In.) 3 Maximum Depth of Cut at 45 Degrees (In.) 2-1/8 Maximum Rip Left of Blade (In.) 13 Maximum Rip Right of Blade (In.) 50 Table in Front of Saw Blade at Maximum Depth of Cut (In.) 10 Maximum Diameter of Dado (In.) 8 Maximum Width of Dado (In.) 13/16 Table Type Cast Iron Table Size (L x W) (In.) 29 x 20 Table Size with Extension (L x W) (In.) 29 x 42 Miter Gauge Type Deluxe Dust Collection Minimum CFM Required (CFM) 350 Dust Port Outside Diameter (In.) 4 Motor Power (HP) 5 -

- Standard Equipment

- Zinc plated 1¾”steel guide tubes.

- 4 Nylatron roller bearing systems.

- Milwaukee Tool Motor

- Adjustable vertical and horizontal rulers.

- Quick change from vertical to horizontal cutting.

- Thin material pressure guard.

- Injection-molded plastic material rollers.

- Spring loaded counter balance system.

- Integrated dust collection bonnet.

- Extended warranty.

- TUV certified to UL/CSA standards

- Standard Equipment

-

Out of stock

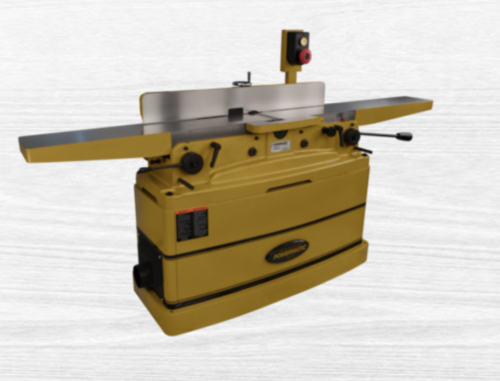

The 8" Parallelogram Jointer offers performance and value in a machine loaded with features. Each machine has an extra long 82" bed length for better work support and is equipped with an innovative single handwheel design that tilts the fence in and out with positive stops at +/-45 and 90 degrees. A non-mar insert in the fence contacts the table to avoid scratching the surface during adjustments. The parallelogram design keeps the table in close proximity to the cutterhead for improved finish and allows for a fast depth of cut adjustment. This design also insures the table remains perfectly parallel, even after years of tough duty. The 1/8" depth limiter control knob gives you quick adjustment ability and safety. A quick twist of the knob will disable this feature. This jointer features a Powermatic controlled chip 3-knife cutterhead for a safe, smooth cut every time. Powerful 2HP motor is totally enclosed in a heavily constructed steel stand providing plenty of power for the most demanding jobs.

The 8" Parallelogram Jointer offers performance and value in a machine loaded with features. Each machine has an extra long 82" bed length for better work support and is equipped with an innovative single handwheel design that tilts the fence in and out with positive stops at +/-45 and 90 degrees. A non-mar insert in the fence contacts the table to avoid scratching the surface during adjustments. The parallelogram design keeps the table in close proximity to the cutterhead for improved finish and allows for a fast depth of cut adjustment. This design also insures the table remains perfectly parallel, even after years of tough duty. The 1/8" depth limiter control knob gives you quick adjustment ability and safety. A quick twist of the knob will disable this feature. This jointer features a Powermatic controlled chip 3-knife cutterhead for a safe, smooth cut every time. Powerful 2HP motor is totally enclosed in a heavily constructed steel stand providing plenty of power for the most demanding jobs.