-

Out of stock

FEATURES: • Dual mitering allows for compound angle cutting of 60° right and 45° left • Tungsten carbide blade guides with precision bearings, stabilizes the blade for increased accuracy and extendes blade life • Large handwheel with blade tensioning gauge acurately measures blade pressure • For added safety, the EHB-1018VM Bandsaw follows strict guidelines and electrical requirements to be certified by CSA Group • Quick positioning vise for clamping of materials • The Elite swing away panel relocates saw controls to a single location, offering finger-tip operation of most major saw functions. • Semi-automatic bow raises after cut to predetermined height • Automatic blade breakage sensor detects accidental breakage and interrupts the power • Heavy-duty construction reduces vibration and deflection • Blade is fully guarded for operators safety

FEATURES: • Dual mitering allows for compound angle cutting of 60° right and 45° left • Tungsten carbide blade guides with precision bearings, stabilizes the blade for increased accuracy and extendes blade life • Large handwheel with blade tensioning gauge acurately measures blade pressure • For added safety, the EHB-1018VM Bandsaw follows strict guidelines and electrical requirements to be certified by CSA Group • Quick positioning vise for clamping of materials • The Elite swing away panel relocates saw controls to a single location, offering finger-tip operation of most major saw functions. • Semi-automatic bow raises after cut to predetermined height • Automatic blade breakage sensor detects accidental breakage and interrupts the power • Heavy-duty construction reduces vibration and deflection • Blade is fully guarded for operators safety -

Out of stock

Vertical Band Saw Voltage 230 2 HP 50 to 5000 sfpm Speeds Max Thickness of Cut 20 In. Max Blade Length 151-1/2 In. Corded Max Blade Width 1 In. Blade Thickness 0.025 In. Overall Height 77-1/2 In. Overall Width 29 In. Overall Depth 40 In. Cutting Angle 10 Degrees Left and 45 Degrees Right 1725 RPM 3 Phase 60 Hz Features Variable Speed Drivetrain Allows Operators to Fine Tune The Blade Speed Fast and Easily Table Dimensions 24 in x 22 In. Application Metal

Vertical Band Saw Voltage 230 2 HP 50 to 5000 sfpm Speeds Max Thickness of Cut 20 In. Max Blade Length 151-1/2 In. Corded Max Blade Width 1 In. Blade Thickness 0.025 In. Overall Height 77-1/2 In. Overall Width 29 In. Overall Depth 40 In. Cutting Angle 10 Degrees Left and 45 Degrees Right 1725 RPM 3 Phase 60 Hz Features Variable Speed Drivetrain Allows Operators to Fine Tune The Blade Speed Fast and Easily Table Dimensions 24 in x 22 In. Application Metal -

Out of stock

Elite Vertical Bandsaws are the perfect blend of power and balance. Featuring variable speed drivetrains with precision balanced cast-iron blade wheels with a bonded rubber blade track, precision ground articulating table, 4.2 KVA Bi-Metal Blade stations, and CSA / CUS Certification make Elite vertical bandsaws the choice for precision sawing of ferrous and non-ferrous materials.

Elite Vertical Bandsaws are the perfect blend of power and balance. Featuring variable speed drivetrains with precision balanced cast-iron blade wheels with a bonded rubber blade track, precision ground articulating table, 4.2 KVA Bi-Metal Blade stations, and CSA / CUS Certification make Elite vertical bandsaws the choice for precision sawing of ferrous and non-ferrous materials. -

Out of stock

Stock Number 311440 Compound Slide Travel (In.) 3-1/2 Cross Slide Travel (In.) 7 Distance Between Centers (In.) 40 Drive EVS Gross Weight (Lbs) 1584 Input Power 230V 3ph Length of Gap (In.) 9-1/2 Max Tool Size (In.) 3/4 x 3/4 Motor (HP) 3 HP, 230V, 3-Phase Motor Phase 3 Motor Power (HP) 3 Motor Voltage (V.) 230 Net Weight (Lbs.) 1320 Number of Inch Threads 34.0000 Number of Longitudinal and Cross Feed Rates 25 Number of Metric Threads 34.0000 Number of Spindle Speeds Variable Overall Dimensions (L x W x H) (In.) 68.5 x 28.3 x 50 Prewired Voltage (V.) 230 Prop 65 Cancer and Reproductive Harm Range of Cross Feeds (IPR) 25 Range of Inch Threads (TPI) 2-56 Range of Longitudinal Feeds (IPR) 0.0016-0.0460 Range of Metric Threads 0.5-12 Range of Spindle Speeds (RPM) 40-2000 Shipping Dimensions (L x W x H) (In.) 76 x 30 x 61 Spindle Bore (In.) 1-1/2 Spindle Mount D1-4 Spindle Taper Morse #5 Spindle Taper with Sleeve MT-5 Spindle Thread (In./TPI) 2 - 56 Steady Rest Capacity (In.) 0.23-0.61 Copper Shaft ( Standard) 0.20-2.36 Bearing Roller(OP) Swing Over Bed (In.) 14 Swing Over Cross Slide (In.) 9-1/16 Tailstock Spindle Travel (In.) 6-1/8 Taper in Tailstock Spindle MT-3 Weight (Lbs.) 1584 Width of Bed (In.) 7.48 -

Out of stock

Door builders and cabinet shops will love the extra capacity of this 37" wide-belt sander. With a 15 HP 3-phase sanding motor, this wide-belt is built for daily industrial use with features such as a heavy-duty steel cabinet, pneumatic belt oscillation, and a built-in air filter/regulator. The digital control pad automates table adjustments and is accurate to 0.005". Also, the variable-speed conveyor, adjustable oscillation controls, and adjustable graphite/felt platen easily allow the operator to find the perfect combination of settings to achieve soft, smooth finishes on all types of wood. Made in an ISO 9001 Factory CSA certified meeting CSA C22.2 #105-1953 and UL 987-7th standards! Specifications

Door builders and cabinet shops will love the extra capacity of this 37" wide-belt sander. With a 15 HP 3-phase sanding motor, this wide-belt is built for daily industrial use with features such as a heavy-duty steel cabinet, pneumatic belt oscillation, and a built-in air filter/regulator. The digital control pad automates table adjustments and is accurate to 0.005". Also, the variable-speed conveyor, adjustable oscillation controls, and adjustable graphite/felt platen easily allow the operator to find the perfect combination of settings to achieve soft, smooth finishes on all types of wood. Made in an ISO 9001 Factory CSA certified meeting CSA C22.2 #105-1953 and UL 987-7th standards! Specifications- Sanding motor: 15 HP, 220V/440V*, 3-phase, 36A/18A, 1725 RPM

- Conveyor motor: 1 HP, 220V/440V*, 3-phase, 3.4A/1.7A

- Table elevation motor: 1/4 HP, 220V/440V*, 3-phase, 1.2A/0.6A, 1725 RPM

- Max. board width: 36-1/2"

- Max. board thickness: 6"

- Min. board length: 14"

- Air requirements: 75 PSI

- Surface speed of drums: 2565 FPM

- Conveyor feed rate: Variable, 15-49 FPM

- Built-in air filter/regulator

- Independent motor control

- Pneumatic belt tracking and tensioning

- Digital sanding load meter

- Emergency stop bar

- Digital readout and control panel

- Three 4" dust ports

- Steel cabinet

- Steel outfeed drum

- Rubber infeed drum

- Rubber pressure rollers

- Micro-adjustable graphite/felt platen

- CSA certified meeting CSA C22.2 #105-1953 and UL 987-7 standards

- Overall size: 52-1/8"W x 69-5/8"H x 49-3/8"D

- Approximate shipping weight: 1800 lbs.

- *440V operation requires purchase of additional components

-

This industrial bandsaw is huge, great attention has been given to the fine points that make it easy to use and performance perfection. The tilt mechanism is manufactured from two pieces of solid cast iron that slide within each other in a dovetail system. There is an ergonomically designed foot brake that shuts the motor off automatically, and easy blade change make operating this bandsaw a joy.

This industrial bandsaw is huge, great attention has been given to the fine points that make it easy to use and performance perfection. The tilt mechanism is manufactured from two pieces of solid cast iron that slide within each other in a dovetail system. There is an ergonomically designed foot brake that shuts the motor off automatically, and easy blade change make operating this bandsaw a joy. -

Out of stock

The POWERMATIC 25-Inch wide belt sander delivers the utmost performance in measurement and sanding, creating a flawless finish every time. The sander has centralized controls which allow the user to access all the needed buttons on one simple panel for more convenience.

The POWERMATIC 25-Inch wide belt sander delivers the utmost performance in measurement and sanding, creating a flawless finish every time. The sander has centralized controls which allow the user to access all the needed buttons on one simple panel for more convenience.- Centralized controls allow you to access all the needed buttons on one simple panel

- The auto thicknesses will capture the piece of wood to give the user the exact starting thickness

- The variable speed feed belt allows you to accurately dial in the exact feed speed to best suit your project

- Digital readout will show the user the exact thickness of the finished piece, or will allow you to preset exactly the thickness you prefer for the finished piece

- The disc brake slows the machine quickly and will activate immediately to stop machine in an emergency

-

Out of stock

The JET JTM-4VS-1 Mill with 3-Axis ACU-RITE VUE DRO (Knee) with X-Axis powerfeed is a variable speed milling machine with a 3-Axis digital readout, with the third Axis on the Knee provides computer assisted precision. The powerfeed provides easier movement and better repeatability. JET mills deliver performance and precision and are backed by an industry leading 2-year warranty.

The JET JTM-4VS-1 Mill with 3-Axis ACU-RITE VUE DRO (Knee) with X-Axis powerfeed is a variable speed milling machine with a 3-Axis digital readout, with the third Axis on the Knee provides computer assisted precision. The powerfeed provides easier movement and better repeatability. JET mills deliver performance and precision and are backed by an industry leading 2-year warranty. -

Out of stock

The POWERMATIC® WP2510 Planer has a solid steel helical cutterhead with four-sided carbide knife inserts that require no adjustments when changing. With a digital readout and simple PC controller, setting up table heights is quick and easy. The frame is machined from heavy cast iron and has extra wide side panels that offer rigid bed support and ensure accurate alignment. The planer's segmented, serrated infeed roll with segmented chip breakers has an independent yield of 1/4. Its automatically adjusting, chain drive gear box powers the 3" diameter infeed rollers, solid pressure bar and dual outfeed rollers for precise feeding of stock. The 3-speed feed selector gives woodworkers flexibility by changing feed rates quickly and easily. The WP2510 Planer has a large 32-3/16" x 26" precision-ground table which contains two adjustable table rollers for smooth feeding of uneven stock. The planer has a Quick-Set micro-adjustable lever that easily raises and lowers the table rollers from 0 to 0.05". The hood features a built-in 5" diameter dust chute. 1547399

The POWERMATIC® WP2510 Planer has a solid steel helical cutterhead with four-sided carbide knife inserts that require no adjustments when changing. With a digital readout and simple PC controller, setting up table heights is quick and easy. The frame is machined from heavy cast iron and has extra wide side panels that offer rigid bed support and ensure accurate alignment. The planer's segmented, serrated infeed roll with segmented chip breakers has an independent yield of 1/4. Its automatically adjusting, chain drive gear box powers the 3" diameter infeed rollers, solid pressure bar and dual outfeed rollers for precise feeding of stock. The 3-speed feed selector gives woodworkers flexibility by changing feed rates quickly and easily. The WP2510 Planer has a large 32-3/16" x 26" precision-ground table which contains two adjustable table rollers for smooth feeding of uneven stock. The planer has a Quick-Set micro-adjustable lever that easily raises and lowers the table rollers from 0 to 0.05". The hood features a built-in 5" diameter dust chute. 1547399 -

Out of stock

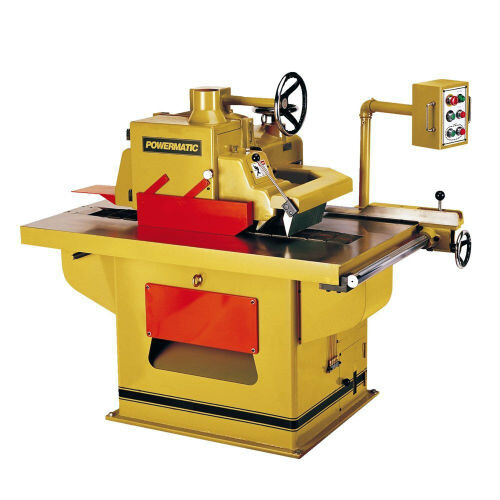

The SLR12 Straight line rip saw has every job covered. Powered by a 15 HP main motor, this saw has the capacity for virtually any job. The 12-Inch main blade mounts on a high alloy, heat treated arbor that is precision ground and dynamically balanced for maximum stability and long durability.

The SLR12 Straight line rip saw has every job covered. Powered by a 15 HP main motor, this saw has the capacity for virtually any job. The 12-Inch main blade mounts on a high alloy, heat treated arbor that is precision ground and dynamically balanced for maximum stability and long durability.- Full cast iron construction for rock-solid operation

- 15 HP Main Motor, 2 HP Feed Motor for large production capacity

- Auto-oiler with shut off, ensures long conveyor chain life

- Seven pressure rollers with dual anti-kickback devices help prevent stock discharge

- Variable feed speeds to accommodate different type stock

-

Out of stock

Jet dual mitering horizontal band saws unique design head dual miters both left and right for Quick angle cuts. The frequency inverter, unique to this saw, allows this EVS saw a full range of blade speeds.

Jet dual mitering horizontal band saws unique design head dual miters both left and right for Quick angle cuts. The frequency inverter, unique to this saw, allows this EVS saw a full range of blade speeds.