-

Out of stock

This 16-Inch jointer offers big capacity and performance in a machine that is loaded with features. Large center-mounted fence assembly adjusts easily on a rack and pinion system with ram lock. Preset stops on the fence body allow for fast angle set-up at 45-degree in and out, and a positive stop for perfect 90-degree angles. The parallelogram design keeps the table in close proximity to the cutterhead for improved finish and allows for a fast depth of cut adjustment. This design also ensures the tables remain perfectly parallel even after years of tough duty. The specially designed solid steel helical cutterhead consists of six rows of precision ground staggered inserts. This system makes fast work of knife changing and never needs adjustment. The heavy-duty 7-1/2 HP motor delivers all the power you need for even the biggest jobs.

This 16-Inch jointer offers big capacity and performance in a machine that is loaded with features. Large center-mounted fence assembly adjusts easily on a rack and pinion system with ram lock. Preset stops on the fence body allow for fast angle set-up at 45-degree in and out, and a positive stop for perfect 90-degree angles. The parallelogram design keeps the table in close proximity to the cutterhead for improved finish and allows for a fast depth of cut adjustment. This design also ensures the tables remain perfectly parallel even after years of tough duty. The specially designed solid steel helical cutterhead consists of six rows of precision ground staggered inserts. This system makes fast work of knife changing and never needs adjustment. The heavy-duty 7-1/2 HP motor delivers all the power you need for even the biggest jobs. -

Out of stock

10 Horsepower 3-Phase 24" Wide Belt Wood Sander with Pneumatic Oscillation Control

These machines were developed in collaboration with James Goodall, a famous luthier, who wanted a machine that could sand very short and very thin pieces. This collaboration resulted in the introduction of the G9962Z & G9962ZX, which have become the "staple" of the guitar building industry. The main features that enable these sanders to process short pieces efficiently are the single drum and double infeed and outfeed pressure rollers positioned close to the drum. The result is a continuous downward pressure on extremely thin stock as short as 9", which is the distance between the first infeed and first outfeed pressure rollers. The feed belt is made of hard rubber to prevent distortion of thin stock while sanding. Features include digital read out, powered table elevation, variable speed conveyor, disc brake stopping system, pneumatic belt tracking, pneumatic belt oscillation, and separate motors for the drum, feed rollers, and table elevation. -

Out of stock

- Wide assortment of finger widths allow greater versatility in the shop

- With fingers installed it can be used as a full-length nose bar, turning the Machine into a straight bending brake

- All body sections are welded Steel plate with heavy truss rods and braces designed to give greater strength and durability

- Both the bed and apron are bored in line to assure the utmost accuracy

- Counter weights can be moved up or down to adjust desired leverage

-

Out of stock

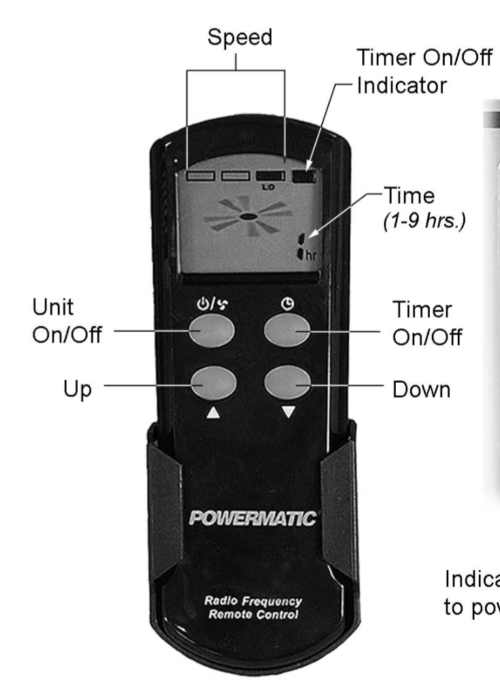

OEM RF Transmitter Assembly Compatiable with: PM 1200 Air Filtration system

OEM RF Transmitter Assembly Compatiable with: PM 1200 Air Filtration system -

Out of stock

Jet Vertical Milling Machines perfrom slot and keyway cutting, planning, drilling, diesinking, rebating and routing with surgical accuracy. With the addition of the Acu-Rite 200S 2 axis digital readout makes this unit readily useable for most applications.

Jet Vertical Milling Machines perfrom slot and keyway cutting, planning, drilling, diesinking, rebating and routing with surgical accuracy. With the addition of the Acu-Rite 200S 2 axis digital readout makes this unit readily useable for most applications. -

Out of stock

The Grizzly Industrial G0445-24" 10 HP 3-Phase Platen Type Wide-Belt Sander machine was developed in collaboration with James Goodall, a famous luthier, who wanted a machine that could sand very short and very thin pieces. The main features that enable it to process short pieces efficiently are the single drum and the double infeed and double outfeed pressure rollers that are tucked in closer to the drum. The result is that you have continuous downward pressure on extremely thin stock as short as 14" (G0582). That is the distance between the first infeed and first outfeed pressure rollers. The feed belt is made of harder rubber to prevent distortion of thin stock while sanding. The new platen model will sand stock as short as 9" (G0445). All of these models include features like digital read out, powered table elevation, four screw jacks for table support, variable speed, disc brake stopping system, dust proof photo electric eye/pneumatic control for belt oscillation, and separate motors for the drum, the feed rollers, and the table elevation.

The Grizzly Industrial G0445-24" 10 HP 3-Phase Platen Type Wide-Belt Sander machine was developed in collaboration with James Goodall, a famous luthier, who wanted a machine that could sand very short and very thin pieces. The main features that enable it to process short pieces efficiently are the single drum and the double infeed and double outfeed pressure rollers that are tucked in closer to the drum. The result is that you have continuous downward pressure on extremely thin stock as short as 14" (G0582). That is the distance between the first infeed and first outfeed pressure rollers. The feed belt is made of harder rubber to prevent distortion of thin stock while sanding. The new platen model will sand stock as short as 9" (G0445). All of these models include features like digital read out, powered table elevation, four screw jacks for table support, variable speed, disc brake stopping system, dust proof photo electric eye/pneumatic control for belt oscillation, and separate motors for the drum, the feed rollers, and the table elevation. -

Out of stock

Vertical Band Saw Voltage 230 2 HP 50 to 5000 sfpm Speeds Max Thickness of Cut 20 In. Max Blade Length 151-1/2 In. Corded Max Blade Width 1 In. Blade Thickness 0.025 In. Overall Height 77-1/2 In. Overall Width 29 In. Overall Depth 40 In. Cutting Angle 10 Degrees Left and 45 Degrees Right 1725 RPM 3 Phase 60 Hz Features Variable Speed Drivetrain Allows Operators to Fine Tune The Blade Speed Fast and Easily Table Dimensions 24 in x 22 In. Application Metal

Vertical Band Saw Voltage 230 2 HP 50 to 5000 sfpm Speeds Max Thickness of Cut 20 In. Max Blade Length 151-1/2 In. Corded Max Blade Width 1 In. Blade Thickness 0.025 In. Overall Height 77-1/2 In. Overall Width 29 In. Overall Depth 40 In. Cutting Angle 10 Degrees Left and 45 Degrees Right 1725 RPM 3 Phase 60 Hz Features Variable Speed Drivetrain Allows Operators to Fine Tune The Blade Speed Fast and Easily Table Dimensions 24 in x 22 In. Application Metal