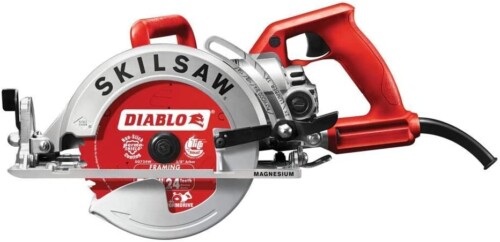

SPT77WML-01

The latest and lightest Worm Drive continues the long tradition of SKIL quality, rugged durability and consistently exceptional cutting performance. Weighing in at just 11.5 lbs., it’s 4 lbs. less than its predecessor and the lightest Worm Drive Skilsaw on the market. The rugged magnesium housing stays strong but keeps the motor cooler, giving you powerful performance job after job. Legendary SKIL Worm Drive technology meets our best-in-class Dual-Field™ motor, invented specifically for saws. This model comes with a SKIL blade.

What's Included: SPT77WML 7-1/4 IN. Magnesium Worm Drive with 24-Tooth Diablo Carbide blade and multi-functional wrench