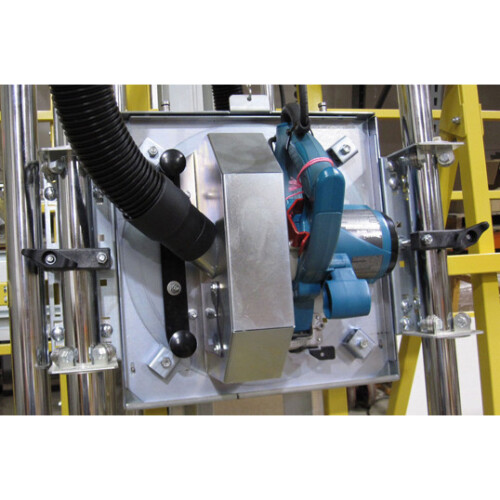

Compact & Powerful Benchtop Press

- Heavy-Duty 3/8" Steel Construction

- Cylinder with 2" Ram and 6-1/4" Stroke

- Rolling Cylinder for Maximum Versatility

- Working Area of 10-1/2" x 20"

- Easy-to-Use Hand/Jog Controls

- Quick Disconnect Hoses

- Hydraulic-Assist Table Height Adjustment

- The compact Edwards 20-Ton Shop Press with single-phase, 230V motor provides smooth, precise and versatile performance. The press can be powered with an Edwards Ironworker with hydraulic accessory pack, or an Edwards Porta Power 5HP, 2750 PSI portable power unit (each sold separately).

Our 20 Ton Shop Press may be small enough to fit on your work bench but it's no lightweight. Smooth and precise, heavy-duty and versatile, the unique open side design allows for material to pass through. Power it up with an Edwards Ironworker with factory installed PowerLink System or an Edwards Portable Power Unit.