-

Out of stock

A VFD (Variable Frequency Drive) with digital readout provides infinitely variable blade speeds between 150 and 3000 FPM, making this saw great for cutting wood and metal alike! Just turn the speed control dial to set the perfect cutting speed for each type of material you're cutting. Besides providing the variable-speed control, the VFD also allows this machine to take full advantage of the high-torque/low-speed characteristics of a 3-phase motor?while only requiring a single-phase power supply. The vertical cutting configuration and massive cast-iron table also makes it easy to feed intricate, curved cuts. All in all, the strong versatility of this 18" Vertical Wood/Metal Bandsaw makes it an ideal choice when shop space is limited and the range of profect types is diverse! Specifications

A VFD (Variable Frequency Drive) with digital readout provides infinitely variable blade speeds between 150 and 3000 FPM, making this saw great for cutting wood and metal alike! Just turn the speed control dial to set the perfect cutting speed for each type of material you're cutting. Besides providing the variable-speed control, the VFD also allows this machine to take full advantage of the high-torque/low-speed characteristics of a 3-phase motor?while only requiring a single-phase power supply. The vertical cutting configuration and massive cast-iron table also makes it easy to feed intricate, curved cuts. All in all, the strong versatility of this 18" Vertical Wood/Metal Bandsaw makes it an ideal choice when shop space is limited and the range of profect types is diverse! Specifications- Motor: 1-1/2 HP, 220V, 3-phase

- Power supply requirement: 220V, single-phase, 15A

- Max. cutting height: 12"

- Throat capacity: 17-1/2"

- Blade length: 133"

- Blade size range: 1/8"?1-1/4"

- Blade speed: variable, 150-3000 FPM

- Table tilt: 45° right, 5°left

- Floor to table height: 37-1/4"

- Table size: 18" x 24"

- Left and right table tilting control

- Upper and lower blade guides

- Precision-ground cast-iron table

- Quick-release blade tension

- Steel guide blocks

- Two dust ports

- Wheel brush on lower wheel

- Frequency drive provides variable speed control

- Fully balanced cast-iron wheels with rubber tires

- Rack-and-pinion adjustment on upper blade guide support

- Blade tension scale with magnified cursor

- Twin drive belts

- Includes rip fence and miter gauge

- Rip fence comes with right and left reading indicators, T-slots for quick change attachments, dead lift quick release, ball bearing slide, solid lever lock

- Overall size: 40"W x 76"H x 31"D

- Approximate shipping weight: 327 lbs.

-

Out of stock

-

- Exclusive variable speed oscillating drum moves from left to right—minimizing visual scratch patterns in workpieces and increasing the lifespan of abrasive paper.

- Sandsmart™ control continuously monitors the load on the drum motor and automatically regulates the speed of the conveyor motor to maintain the highest feed rate without overload

- Dust hood includes an integrated channel that mirrors the shape of the drum and directs chips and dust to the 4" collection port

- Conveyor bed parallelism is easily adjusted by turning the dial on the outside of the bed - no tools required

- Redesigned conveyor system pulls the work piece through the sander instead of pushing

- Precision-machined and dynamically balanced extruded aluminum drum is designed to dissipate heat and has 3/4" of oscillating stroke

- Infinitely variable speed control of up to 10 feet per minute allows the user to choose the optimal feed rate

- Conveyor belt TRACKERS™ reduce the need for manual belt adjustments

- Tool less abrasive take-up clips make changing abrasives quick and easy

- Mobile cabinet features a heavy duty 45" x 24" footprint to increase stability and has a door to keep items stored securely

- Snipe is virtually eliminated thanks to the adjustable tension rollers that apply downward pressure to the work piece

- One rotation of the top-position hand wheel adjusts the drum height by 1/16"

-

Drum Length (In.) 23 Drum Speed (RPM) 1725 Drum Diameter (In.) 5 Conveyor Motor totally enclosed DC Conveyor Speed (FPM) 0-10 Maximum Board Thickness (In.) 4 Maximum Board Width (In.) 44 (two passes) Minimum Board Length (In.) 2-3/8 Minimum Board Thickness (In.) 1/32 Dust Port Outside Diameter (In.) 4 Motor Power (HP) 1-3/4 Motor Phase (PH) 1 Motor Voltage (V) 115 Motor Amps 15 Recommended Circuit Size (Amps.) 20

-

-

Out of stock

Number of Knives 54 Helical Knife Size (L x W x T) (In.) 15 x 15 x 2.5 Cutterhead Speed (RPM) 7,000 Cutting Capacity (W x D) (In.) 8 x 1/2 Table Size (L x W) (In.) 73 x 8-1/2 Table Height from Floor (In.) 32 Infeed Table Length (In.) 35-1/4 Outfeed Table Length (In.) 35-1/2 Rabbeting Capacity (In.) NA Fence Size (L x H) (In.) 38 x 4-3/4 Fence Tilt (Deg.) 45 Forward, 45 Backward Fence Positive Stops (Deg.) 45, 90, -45 Dust Collection Minimum CFM Required (CFM) 450 Dust Port Outside Diameter (In.) 4 Motor Power (HP) 2 Motor Phase 1 Motor Voltage (V.) 230 only Motor Current (Amps) 9 Recommended Circuit Size (Amps.) 20 -

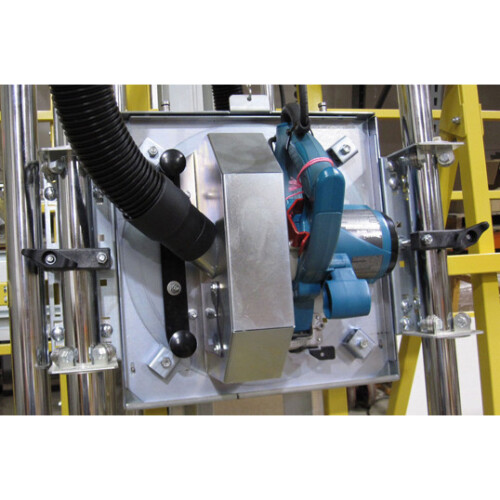

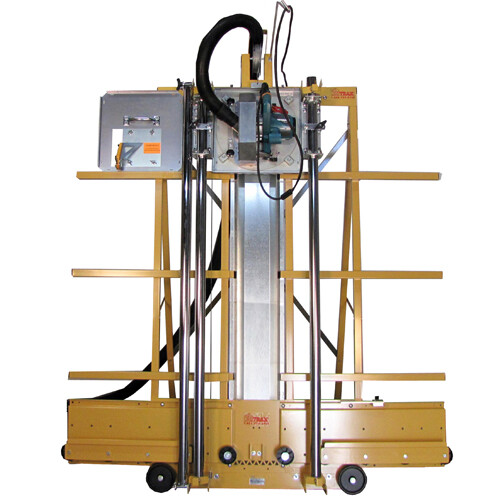

Sign Shops cut a variety of material, not just wood, materials such as aluminum composites, corrugated plastics, foam board, PVC material, wood and much more. For some time, sign shops had to use different machines to cut each material. Thankfully, those days are gone, with the help of our Sign Maker’s Series. C52SM model features a 60" wide frame for size restricted shops and a 52" vertical cut. Also available in Full Size models. [fusion_checklist icon="check" iconcolor="#aaaaaa" circle="no"]

Sign Shops cut a variety of material, not just wood, materials such as aluminum composites, corrugated plastics, foam board, PVC material, wood and much more. For some time, sign shops had to use different machines to cut each material. Thankfully, those days are gone, with the help of our Sign Maker’s Series. C52SM model features a 60" wide frame for size restricted shops and a 52" vertical cut. Also available in Full Size models. [fusion_checklist icon="check" iconcolor="#aaaaaa" circle="no"]- Compact 60" Wide Frame

- Makita 5007F 7.25" saw

- Spinning saw insert plate

- Spring Hold Down

- Pivoting Knife Cutter

- Dust hood, hose, brush

- Folding Stand and Wheels

- Dual Rip Gauge

- Stop, Bar and Tapes

- Patented Accu-Square System

- Sealed Steel Bearings

-

The Sjobergs Elite line of workbenches represents the highest quality you can get in a professional workbench. Strong, sturdy, and handsomely crafted, the Sjobergs Elite 2000 Workbench is unmatched in quality.

The Sjobergs Elite line of workbenches represents the highest quality you can get in a professional workbench. Strong, sturdy, and handsomely crafted, the Sjobergs Elite 2000 Workbench is unmatched in quality.- Massive vises with 740 mm/29" width & 145mm/5 3/4" capacity

- Double row of dog holes running from any vise location

- Includes 4 unbreakable round 1" steel bench dogs

- Holdfast can be located in work top or the front legs

- Optional accessories kit includes one 1” Holdfast, one Universal Anvil, and a set of Jaw Cushions

- Constructed of European beech and thoroughly treated with top-quality oil

- Left- or right-handed use

-

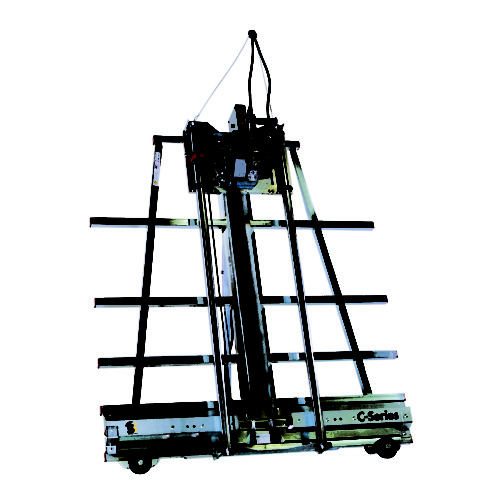

DESCRIPTION

The C4 model packs all of the features of the full-size saws into a portable 5′ frame. This panel saw can travel to work sites and fit into shops with limited floor space. The C4 is ideal for cutting 4’–8′ sheets of material. Standard Equipment- 3 ¼ Hp, 15 amp industrial duty saw motor.

- Zinc plated 1 ¾” steel guide tubes.

- 4 Nylatron roller bearing systems.

- Adjustable vertical and horizontal rulers.

- Quick change from vertical to horizontal cutting.

- Thin material pressure guard.

- Injection-molded plastic material rollers.

- Spring loaded counter balance system.

- Integrated dust collection bonnet.

- Extended warranty.

- TUV certified to UL/CSA standards

- Wall mounted

- QUICK STOP™ Gauge 5 ft./2.44m

- Dust collection kit (vacuum additional)

- Fixed stand/folding stand with C-Series

- Set of wheels

- 860ATB Foam Core Saw Blade

- Folding stand

-

-

The P|Flux series gets a host of exciting new upgrades including an auto-cleaning feature standard on all models in this line. The auto-clean conveniently activates every 10 minutes, or you can simply activate from the sleek redesigned remote. Overfilling the drum is a thing of the past, thanks to the super-sized 46 gallon octagonal drum (P|Flux 2 and 3), and a bright LED light illuminating the drum on all P|Flux models. Plus, LED and audio warning lets you know when the drum is full – features that are now standard in this line.

Specs:

Motor Specs: 2 HP

Electrical Specs: 220V / 60Hz / 1PH / 3450 RPM

Running AMP: (6” inlet) 14A at 220V

Air Volume: 1166 CFM (cubic feet per minute)

Max. static pressure: 9.3 Inches of water

Fan size: 14.5”

Inlet: Ø6” (Ø 8” BY Ø 6” PORT) OR (Ø 8” BY Ø 4” X 2 PORTS)

Switch: High frequency remote control switch

Collection capacity: 46-gallon Octagon drum

Packing Size: (L x W x H)

50” x 31.5” x 50.6”

(127 x 80 x 128.5 cm)

Machine weight: 362 lbs. (164 kgs)

Shipping weight: 430 lbs. (195 kgs)

Filter Media: filtering area: 102 sq/ft (9.5 M2)

Cartridge Filter: Black HEPA 15.74” x 35.43” (Ø40 x 90cm) x 1pc

-

Out of stock

Integrated LED Control Panel shows power, belt speed, and DRO. Equipped with Feed Logic to produce exceptional finish while preventing machine overload. Secondary, absolute depth scale provides an additional height reading. Drum carriage is cast iron to provide greater strength and consistent performance. Steel hood with a 4 dust port provide excellent dust collection.

Integrated LED Control Panel shows power, belt speed, and DRO. Equipped with Feed Logic to produce exceptional finish while preventing machine overload. Secondary, absolute depth scale provides an additional height reading. Drum carriage is cast iron to provide greater strength and consistent performance. Steel hood with a 4 dust port provide excellent dust collection.