-

Out of stock

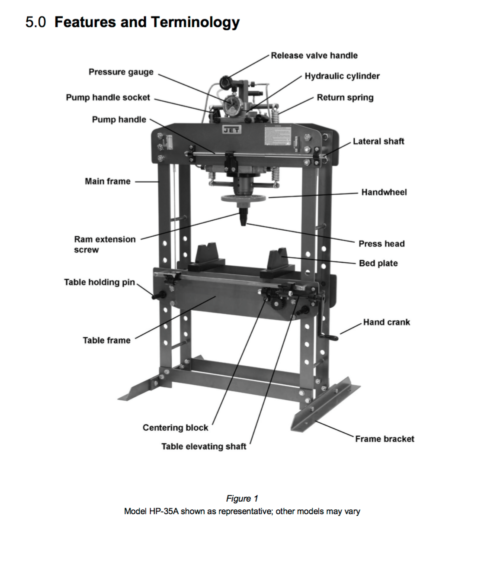

JET’s Hydraulic Shop Press line consists of a 5, 15 and 35 ton hydraulically powered H frame press. Each machine is built using heavy steel plate that is electro welded together, and comes standard with industrial grade hydraulics. These machines are for the serious fabrication and machine shop owner who demands only the best quality from his operation.

JET’s Hydraulic Shop Press line consists of a 5, 15 and 35 ton hydraulically powered H frame press. Each machine is built using heavy steel plate that is electro welded together, and comes standard with industrial grade hydraulics. These machines are for the serious fabrication and machine shop owner who demands only the best quality from his operation. -

This planer is simply a reliable, heavy-duty 20" planer. If you need a 20" Planer that you can rely upon to get the job done with quality results and trouble-free operation, then look no further. There have been versions of the G1033 in the Grizzly line for over 20 years with tens-of-thousands of them sold and smoothly churning out countless board feet of material on a daily basis. We are reintroducing this no-frills, all-performance classic version from an extremely reliable Taiwanese factory. While still feature-packed, it has only the most highly-desired features to keep the value up and the price as low as possible.

This planer is simply a reliable, heavy-duty 20" planer. If you need a 20" Planer that you can rely upon to get the job done with quality results and trouble-free operation, then look no further. There have been versions of the G1033 in the Grizzly line for over 20 years with tens-of-thousands of them sold and smoothly churning out countless board feet of material on a daily basis. We are reintroducing this no-frills, all-performance classic version from an extremely reliable Taiwanese factory. While still feature-packed, it has only the most highly-desired features to keep the value up and the price as low as possible. -

DESCRIPTION

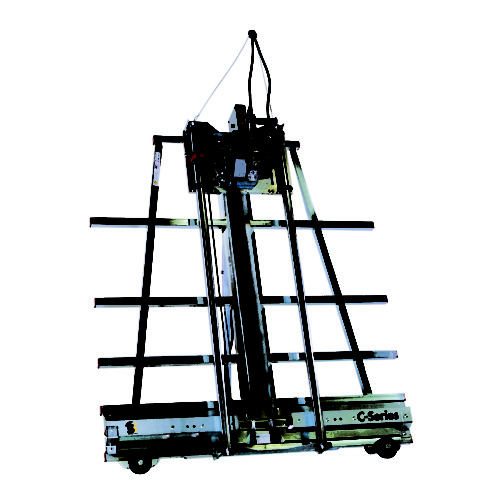

The C4 model packs all of the features of the full-size saws into a portable 5′ frame. This panel saw can travel to work sites and fit into shops with limited floor space. The C4 is ideal for cutting 4’–8′ sheets of material. Standard Equipment- 3 ¼ Hp, 15 amp industrial duty saw motor.

- Zinc plated 1 ¾” steel guide tubes.

- 4 Nylatron roller bearing systems.

- Adjustable vertical and horizontal rulers.

- Quick change from vertical to horizontal cutting.

- Thin material pressure guard.

- Injection-molded plastic material rollers.

- Spring loaded counter balance system.

- Integrated dust collection bonnet.

- Extended warranty.

- TUV certified to UL/CSA standards

- Wall mounted

- QUICK STOP™ Gauge 5 ft./2.44m

- Dust collection kit (vacuum additional)

- Fixed stand/folding stand with C-Series

- Set of wheels

- 860ATB Foam Core Saw Blade

-

Out of stock

T10718 50" Deluxe Pan and Box Brake

Easily form transverse or down-flanged parts.

The T10718 50" Deluxe Pan and Box Brake is used to make straight bends, boxes, pans, and trays in sheet metal that is 12-gauge or thinner. Clamping fingers and bending blocks of different lengths can be arranged to make 90° bends of varying widths up to 50" wide. The fingers and blocks can be spaced in any configuration necessary to permit the sides of a box to be bent without interfering with previously bent sides. Setback and clamping pressure are easily adjusted for different workpiece requirements, and the adjustable bending stop is used to make repetitive bends of the same angle.Perfect for shops doing signs, fabrication, HVAC, or architectural sheet metal!

Like all Grizzly pan and box brakes, the T10718 comes with a 1-year warranty which covers parts and assures the unit is free from factory defects. The T10718 manual was written by our U.S. based Technical Documentation Department and is packed with useful information. The complete and easy-to-read manual makes it easier to assemble and maintain your pan and box brake. The Grizzly Customer Service and Technical Support Teams are U.S. based. Parts and accessories for the pan and box brake are available online and shipped from the Grizzly parts warehouse in Springfield, MO.SPECIFICATIONS:

- Maximum working width: 50"

- Maximum sheet metal thickness: 16-gauge mild steel at full width

- Maximum height of pan/box sides: 2"

- Minimum reverse bend: 5/8"

- Maximum bending angle: 135°

- Overall dimensions: 63" W x 38" D x 44-3/4" H

- Approximate shipping weight: 945 lbs.

-

Out of stock

- Motor size: 5 HP

- Tablesaw type: Cabinet

- Blade size: 10"

- Maximum cutting height @ 90deg: 3"

- Maximum cutting height @ 45deg: 2-1/8"

- Maximum ripping capacity - right: 60"

- Table type: Precision-Ground Cast Iron

- Overall table size: 74" x 27"

- Shipping weight: 550 lbs.

-

The helical cutterhead delivers near mirror-smooth finishes right out of the gate. It consists of four rows of 52 indexable carbide inserts, each angled slightly to produce a shearing action. This shearing action results in less tearout in highly figured woods and quieter operation—and the planed surfaces are far superior to what you'll get with 15" straight-knife or other spiral cutterheads on the market. SPECIFICATIONS:

The helical cutterhead delivers near mirror-smooth finishes right out of the gate. It consists of four rows of 52 indexable carbide inserts, each angled slightly to produce a shearing action. This shearing action results in less tearout in highly figured woods and quieter operation—and the planed surfaces are far superior to what you'll get with 15" straight-knife or other spiral cutterheads on the market. SPECIFICATIONS:- Motor: 3 HP, 230V, single-phase, 12A

- Maximum stock width: 15"

- Maximum stock thickness: 6"

- Minimum stock thickness: 3/16"

- Minimum stock length: 6"

- Maximum cutting depth: 1/8"

- Cutterhead diameter: 3"

- Cutterhead type: 4-row helical with 52 inserts

- Cutterhead speed: 5000 RPM

- Insert size and type: 15 x 15 x 2.5mm, indexable carbide

- Feed rate: Variable, 10–28 FPM

- Table size with extensions: 15" x 48"

- Dust port size: 4"

- Footprint: 22-1/2" x 23"

- Overall dimensions: 39" W x 48" D x 44-1/2" H

- Approx. shipping weight: 595 lbs.

-

-

- Features round and square 3/4 in (19 mm) bench dog holes

- Large shoulder vise won’t rack when clamping off-center

- No vise hardware to get in your way when working on long pieces

- Includes a 4-pack of round 3/4 in (19 mm) bench dogs and a 2-pack of square 3/4 in (19 mm) bench dogs

- SM05 bench has 3 sliding drawers, 2 cupboard doors, and 3 cubbies

- Original 1900 workbench was previously named the SB119 workbench

-

Out of stock

The Powermatic DS20 20" Disc Sander is ideal for the professional or serious home woodworking shop. It has direct drive from motor to disc for maximum efficiency, with a hand activated brake for quick stoppage of disc. The DS20 sander has an extra large sanding surface, adjustable tilting work table, and sturdy cast iron base. The swing away guard makes changing abrasive discs quick and easy.

The Powermatic DS20 20" Disc Sander is ideal for the professional or serious home woodworking shop. It has direct drive from motor to disc for maximum efficiency, with a hand activated brake for quick stoppage of disc. The DS20 sander has an extra large sanding surface, adjustable tilting work table, and sturdy cast iron base. The swing away guard makes changing abrasive discs quick and easy. -

Out of stock

The Powermatic DS20 20" Disc Sander is ideal for the professional or serious home woodworking shop. It has direct drive from motor to disc for maximum efficiency, with a hand activated brake for quick stoppage of disc. The DS20 sander has an extra large sanding surface, adjustable tilting work table, and sturdy cast iron base. The swing away guard makes changing abrasive discs quick and easy.

The Powermatic DS20 20" Disc Sander is ideal for the professional or serious home woodworking shop. It has direct drive from motor to disc for maximum efficiency, with a hand activated brake for quick stoppage of disc. The DS20 sander has an extra large sanding surface, adjustable tilting work table, and sturdy cast iron base. The swing away guard makes changing abrasive discs quick and easy. -

Sale!

Out of stock

- Motor: 1 HP

- Swing: 9 in.

- Distance between centers: 22 in.

- Spindle bore: 25 mm

- Spindle type: Threaded

- Speeds: 100 – 2000 RPM

- Tailstock taper: MT#3

- Tailstock barrel travel: 2-1/2 in.

- Shipping weight: 453 lbs.