- Motor: 7.5 HP

- Tablesaw type: Cabinet

- Blade size: 12 in.

- Maximum cutting height @ 90deg: 4 in.

- Maximum cutting height @ 45deg: 2-3/4 in.

- Maximum ripping capacity - right: 36 in.

- Table type: Precision-Ground Cast Iron

- Overall table size: 48-1/4 in. x 30 in.

- Shipping weight: 698 lbs.

-

-

Out of stock

tem Number IP-156-HH Shipping Weight 600lbs Table Size (Length) 48" Table Size (Width) 15" RPM 5000 Maximum Depth of Cut (Resaw) 1/8" Cutter Head Diameter 3" Max Stock Width 15' Maximum Stock Height 6" Minimum Stock Thickness 3/16" Minimum Stock Length 6" Feed Speed 16/20 FPM Table Elevation Manual Power 220V Single Phase Horse Power 3 Weight (lbs) 520 Number of Inserts 68 Insert Rows 4 Shipping Dimensions (Inches) 60x44x52 -

Out of stock

Motorized Sliding Bed – Increase spindle length 20” up to 40” • Motor & Switch – Beefy 3HP motor delivers ample power • Index Head – 3-Step, multi-V pulleys include 36 index positions • Control Box – Magnetic back positions controls anywhere on long bed • LCD Speed Display – Big easy-to-read speeds from 20 to 3850 RPMs • Banjo – Cast iron tool rest base is extra wide and sturdy

RIKON’s Heavy Duty 70-3040 Variable Speed Lathe features an innovative SLIDING BED that increases your turning capacity with just a turning of a switch! The special motorized upper bed effortlessly moves to the rightaway from the headstock to double the standard between-centers distance from 20” to 40”! Moving the sliding bed also increases the swing from 25-3/16” to 31-13/16” over the lower bed! Ideal for turning large bowls or platters. This space-saving lathe is extra heavy-duty, made of solid cast iron and steel construction to provide professional turners with a robust machine that will take the stress when turning large diameter bowls or spindles. The 3HP TEFC, 220V motor combined with 4 heavy-duty bearings in the headstock and digital speed controls provide all the power and precision needed for this versatile lathe.» Read Less

-

This Extreme Table Saw is ideally suited to handling large panels without blinking an eye. A right-hand and rear-mounted extension table supports the widest panels before, during, and after the cut, and the large rail-mounted switch control won't get lost under the panel. Other features include ample storage shelves, a user friendly blade guard, a riving knife, a digital readout for blade angle and an efficient dust management system that includes an internal dust port and sloped cabinet floor that directs saw dust into the 4" dust port. Enjoy all of the innovative features this big capacity saw has to offer. CSA certified meeting CSA C22.2 #71.2-08, CSA C22.2 #105-1953, and UL 987 standards. Made in an ISO 9001 Factory. SPECIFICATIONS:

This Extreme Table Saw is ideally suited to handling large panels without blinking an eye. A right-hand and rear-mounted extension table supports the widest panels before, during, and after the cut, and the large rail-mounted switch control won't get lost under the panel. Other features include ample storage shelves, a user friendly blade guard, a riving knife, a digital readout for blade angle and an efficient dust management system that includes an internal dust port and sloped cabinet floor that directs saw dust into the 4" dust port. Enjoy all of the innovative features this big capacity saw has to offer. CSA certified meeting CSA C22.2 #71.2-08, CSA C22.2 #105-1953, and UL 987 standards. Made in an ISO 9001 Factory. SPECIFICATIONS:- Motor: 7-1/2 HP, 220V/440V*, 3-phase

- Amps 19.5/10

- Blade tilt: Left, 45 degrees

- Table height from floor: 35-3/4"

- Table size with extension 69-1/2" x 78-3/4"

- Arbor speed: 3600 RPM

- Arbor size: 1"

- Maximum dado width: 3/4"

- Maximum depth of cut @ 90°: 4"

- Maximum depth cut @ 45°: 2-3/4"

- Maximum rip capacity: 52"

- Distance from front of table to blade at maximum blade height: 11-1/2"

- Distance from front of table to center of blade: 17-1/4"

- Overall dimensions: 91-1/2" W x 79-1/2" D x 42-1/2" H

- Approximate shipping weight: 861 lbs.FEATURES:

- Precision-ground cast iron table

- Cast iron trunnions

- 3/8" x 3/4" T-slots & miter gauge

- 4" dust port

- Smooth and quiet Poly-V serpentine belt power transfer

- Steel cabinet

- Hinged motor cover

- Right hand and rear extension tables

- Magnetic switch with thermal overload protection and lock-out padlock

- Digital readout for bevel angle

- Quick-change between riving knife and splitter guard

- Includes 12" x 60T blade and push stick*If you require 440 volt operation, Grizzly must convert your machine at the time of purchase to maintain the machine's warranty. A $250 fee will be added to your order. Please allow extra shipping time for the conversion. If you need more information please contact technical service

-

The 13" Combination Brush/Drum is the answer to your production bottleneck. Developed with mouldings in mind, this versatile sander can tackle every step in your finishing process, from sanding raw wood to sanding in between coats of stain or primer. Read about other applications below. This model features a 1-3/4 HP motor, and can handle stock up to 4" thick, or as thin as 1/32". It can also be equipped with an optional sanding drum for surface sanding.

The 13" Combination Brush/Drum is the answer to your production bottleneck. Developed with mouldings in mind, this versatile sander can tackle every step in your finishing process, from sanding raw wood to sanding in between coats of stain or primer. Read about other applications below. This model features a 1-3/4 HP motor, and can handle stock up to 4" thick, or as thin as 1/32". It can also be equipped with an optional sanding drum for surface sanding.- Raw Wood Sanding | White Wood Sanding

- Break sharp edges

- Open grain for even finish absorption

- Blend out minor defects

- Sealer Sanding | Primer Sanding | Scuff Sanding

- Removes raised fibers and grain (denib/defuzz)

- Degloss previously finished wood

- Clean reclaimed wood

- Wire Brushing

- Distress (weathered/Southwest finish)

- Pull out soft grain to create textured surface

- Raw Wood Sanding | White Wood Sanding

-

-

Out of stock

• Powerful 3 HP Motor • 4 Row Helical Head Design • Precision Cast Iron Tables • Heavy Duty Design • Rubber Outfeed Rollers • Dual Planer / Jointer Combination

12” Planer / Jointer #25-210H are equipped with a larger 12” cutter head and powerful 3HP motors that make quick work in milling the hardest, or widest rough-sawn lumber. A favorite of production shops, the jointer andplaner tables are made of heavy, cast iron and machined smooth for efficient movement through the cutters. Unique, one-piece jointer tables easily lift up and out of the way for planer use, or to work on the cutter head. The #25-210H has a 4-row, helical cutter head with 56 four-sided, carbide insert cutters. 220V motors require 3-wire electrical plugs to match your electrical receptacles. -

Out of stock

4/2020 Latest version

4/2020 Latest version -

Out of stock

The features you love on the 3520B lathe are now available in a smaller footprint. The PM2020 lathe is perfect for turners short on space, or projects where a short bed is convenient. Like its big brother, the PM2020 features a sliding headstock, electronic variable speed with low and high speed ranges, and the spindle lock. The enhanced features include a digital RPM readout, built in spindle indexing on the head stock, and a re-designed tailstock with internal storage, chrome trimmed handwheels, and a laser etched quill which is self-ejecting. Additional features include a two position mount for the optional bed extension, a sliding hammer knockout rod with brass tip, an attached tool caddy and a metal shelf for tool storage.

The features you love on the 3520B lathe are now available in a smaller footprint. The PM2020 lathe is perfect for turners short on space, or projects where a short bed is convenient. Like its big brother, the PM2020 features a sliding headstock, electronic variable speed with low and high speed ranges, and the spindle lock. The enhanced features include a digital RPM readout, built in spindle indexing on the head stock, and a re-designed tailstock with internal storage, chrome trimmed handwheels, and a laser etched quill which is self-ejecting. Additional features include a two position mount for the optional bed extension, a sliding hammer knockout rod with brass tip, an attached tool caddy and a metal shelf for tool storage. -

Sale!

The G0701 19" Ultimate Bandsaw is made for production work with its large cutting capacities, foot brake, resaw fence and motorized upper blade guide. The 5 HP motor powers through wood at a maximum 19-1/2" cutting capacity and the 18-3/8" throat is big enough for most applications. No more cumbersome two-handed height positioning! Simply toggle the switch up or down for motorized blade guide adjustments. The G0701 has an extra-wide 28" x 24" cast-iron table that can tilt from 5° left to 45° right. The cast-iron fence includes an extruded-aluminum resaw fence that attaches quickly and supports tall stock exceptionally well. The cast-iron table trunnions add additional weight for greater stability. You'll also appreciate the computer balanced cast-iron wheels with rubber tires for the smoothest operation possible, blade tension gauge and rack and pinion table tilt adjustment. Made in an ISO 9001 factory CSA certified

The G0701 19" Ultimate Bandsaw is made for production work with its large cutting capacities, foot brake, resaw fence and motorized upper blade guide. The 5 HP motor powers through wood at a maximum 19-1/2" cutting capacity and the 18-3/8" throat is big enough for most applications. No more cumbersome two-handed height positioning! Simply toggle the switch up or down for motorized blade guide adjustments. The G0701 has an extra-wide 28" x 24" cast-iron table that can tilt from 5° left to 45° right. The cast-iron fence includes an extruded-aluminum resaw fence that attaches quickly and supports tall stock exceptionally well. The cast-iron table trunnions add additional weight for greater stability. You'll also appreciate the computer balanced cast-iron wheels with rubber tires for the smoothest operation possible, blade tension gauge and rack and pinion table tilt adjustment. Made in an ISO 9001 factory CSA certifiedSPECIFICATIONS:

- Motor: 5 HP, 230V, single-phase, 22A

- Guide post motor: Universal DC, 40W

- Cutting capacity/throat: 18-3/8"

- Maximum cutting height: 19-1/2"

- Table size: 28" x 24"

- Table tilt: 5° left, 45° right

- Floor to table height: 35-1/4"

- Blade size: 166–168" long

- Blade width range: 3/8 – 1-3/8"

- Blade speed: 4975 FPM

- Footprint: 31" x 23-1/2"

- Overall size: 86-1/2" H x 36-5/8" W x 33" D

- Approximate shipping weight: 810 lbs.

-

Sale!

This machine is outfitted with stops and clamps, so you can quickly insert pre-cut boards, clamp them in place, and start cutting. With the ability to cut two joints at a time, these dovetail machines can produce a 4-sided drawer in under two minutes if the boards are prepared properly. Includes a 4-sided template for cutting 1", 1-1/2", 2", and 2-1/2" dovetails. Also spindle heads are micro-adjustable to give you complete control of dovetail "fit."

This machine is outfitted with stops and clamps, so you can quickly insert pre-cut boards, clamp them in place, and start cutting. With the ability to cut two joints at a time, these dovetail machines can produce a 4-sided drawer in under two minutes if the boards are prepared properly. Includes a 4-sided template for cutting 1", 1-1/2", 2", and 2-1/2" dovetails. Also spindle heads are micro-adjustable to give you complete control of dovetail "fit." -

Out of stock

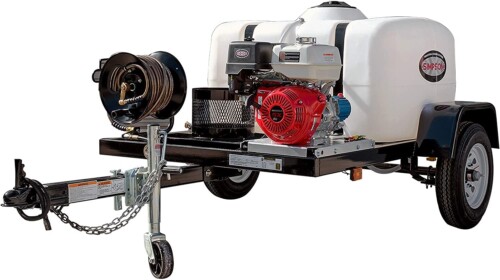

Engineered for top performance, the SIMPSON pressure washer trailer 3800 PSI at 3. 5 GPM is a self contained cleaning machine. Designed to utilize the power and performance from top of the line SIMPSON pressure washers matched with the portability of a utility trailer, it lets you bring a cleaning solution into the field, where water supply is an issue. The 95001 is run by a Honda engine and comes with a 100’ hose, an ergonomic spray gun and 5 Quick-Connect nozzles. This powerful SIMPSON mobile pressure washing system will handle all your commercial jobs. It is perfectly suited for contract cleaners, mobile detailers, municipalities and resorts. The trailer is dot certified as an over-the-road pressure washer system. Job-Site set-up is a snap. Pull up to the work area, connect the spray gun, start the engine and begin cleaning. Warranty Details: Engine - 3 Year Limited Commercial Warranty | Pump - 5 Year Limited Warranty | Frame - 1 Year Limited Warranty

Engineered for top performance, the SIMPSON pressure washer trailer 3800 PSI at 3. 5 GPM is a self contained cleaning machine. Designed to utilize the power and performance from top of the line SIMPSON pressure washers matched with the portability of a utility trailer, it lets you bring a cleaning solution into the field, where water supply is an issue. The 95001 is run by a Honda engine and comes with a 100’ hose, an ergonomic spray gun and 5 Quick-Connect nozzles. This powerful SIMPSON mobile pressure washing system will handle all your commercial jobs. It is perfectly suited for contract cleaners, mobile detailers, municipalities and resorts. The trailer is dot certified as an over-the-road pressure washer system. Job-Site set-up is a snap. Pull up to the work area, connect the spray gun, start the engine and begin cleaning. Warranty Details: Engine - 3 Year Limited Commercial Warranty | Pump - 5 Year Limited Warranty | Frame - 1 Year Limited Warranty -

- INTELLISAND Technology: Automatically adjusts conveyor speed based on load which prevents gouging, damaging or burning stock. This Provides consistent finish even with varying grain pattern

- Flatness Guarantee: Precision-flattened steel conveyor bed reinforced with four steel cross sections for no "flex" in conveyor, guaranteeing flatness to less than .010" across the width of the sander

- Abrasive conveyor belt offers the best grip for raw wood, giving you the ability to accommodate stock that is much shorter or thinner

- Patented Abrasive Attachment System effectively tensions the abrasive wraps, preventing loose abrasive and overlap

- Easiest access to abrasive fastening system of any drum sander! Machine design includes additional space around abrasive, eliminating the need for special tools

- Self-cooling drum prevents overheating and extends abrasive life

- Maximum Width: 37"

- Minimum Length: 3-1/2"

- Maximum Thickness: 12"

- Minimum Thickness (in): 1/32"

- 43" x 58" x 31"

- 5" x 37" (extruded aluminum)

- 1740 RPM

- 4" vacuum ports, min. 1800 CFM recommended

- 4, sealed and permanently lubricated

- Base with Casters

- 100 in. -lb. torque, direct drive D.C motor, ranged variable, 0-15 FPM

- 5 HP

- 208-230V, 60HZ; 1 Ph, 30 amp service; 3 Ph 20 amp service

- 525 lbs

-

Out of stock

This powerful SIMPSON mobile pressure washing system will handle all your commercial jobs. It is perfectly suited for contract cleaners, mobile detailers, municipalities and resorts. The trailer is dot certified as an over-the-road pressure washer system. Job-Site set-up is a snap. Pull up to the work area, connect the spray gun, start the engine and begin cleaning. The SIMPSON mobile pressure washer 4200 PSI at 4. 0 GPM is a self-contained cleaning machine. Engineered to utilize the power and performance from top of the line SIMPSON pressure washers, it’s matched with the portability of a utility trailer. The 95002 is run by a Honda engine and comes with a 100’ hose, an ergonomic spray gun and 5 Quick-Connect nozzles. This mobile system brings a cleaning solution into the field where water supply is an issue. This powerful SIMPSON mobile pressure washing system will handle all your commercial jobs. It is perfectly suited for contract cleaners, mobile detailers, municipalities and resorts. The trailer is dot certified as an over-the-road pressure washer system. Job-Site set-up is a snap. Pull up to the work area, connect the spray gun, start the engine and begin cleaning.Warranty Details: Engine - 3 Year Limited Commercial Warranty | Pump - 5 Year Limited Warranty | Frame - 1 Year Limited Warranty

This powerful SIMPSON mobile pressure washing system will handle all your commercial jobs. It is perfectly suited for contract cleaners, mobile detailers, municipalities and resorts. The trailer is dot certified as an over-the-road pressure washer system. Job-Site set-up is a snap. Pull up to the work area, connect the spray gun, start the engine and begin cleaning. The SIMPSON mobile pressure washer 4200 PSI at 4. 0 GPM is a self-contained cleaning machine. Engineered to utilize the power and performance from top of the line SIMPSON pressure washers, it’s matched with the portability of a utility trailer. The 95002 is run by a Honda engine and comes with a 100’ hose, an ergonomic spray gun and 5 Quick-Connect nozzles. This mobile system brings a cleaning solution into the field where water supply is an issue. This powerful SIMPSON mobile pressure washing system will handle all your commercial jobs. It is perfectly suited for contract cleaners, mobile detailers, municipalities and resorts. The trailer is dot certified as an over-the-road pressure washer system. Job-Site set-up is a snap. Pull up to the work area, connect the spray gun, start the engine and begin cleaning.Warranty Details: Engine - 3 Year Limited Commercial Warranty | Pump - 5 Year Limited Warranty | Frame - 1 Year Limited Warranty -

Out of stock

The SIMPSON trailer pressure washer 3200 PSI at 2.8 GPM is a self-contained cleaning machine. Engineered to utilize the power and performance from top of the line SIMPSON pressure washers matched with the portability of a utility trailer. The 95000 is run by a Honda engine and comes with a 50’ hose, an ergonomic spray gun and 5 Quick-Connect nozzles. This mobile system brings a cleaning solution into the field where water supply is an issue. This powerful SIMPSON mobile pressure washing system will handle all your commercial jobs. It is perfectly suited for contract cleaners, mobile detailers, municipalities and resorts. The trailer is dot certified as an over-the-road pressure washer system. Job-Site set-up is a snap. Pull up to the work area, connect the spray gun, start the engine and begin cleaning. Warranty Details: Engine - 3 Year Limited Commercial Warranty | Pump - 5 Year Limited Warranty | Frame - 1 Year Limited Warranty

The SIMPSON trailer pressure washer 3200 PSI at 2.8 GPM is a self-contained cleaning machine. Engineered to utilize the power and performance from top of the line SIMPSON pressure washers matched with the portability of a utility trailer. The 95000 is run by a Honda engine and comes with a 50’ hose, an ergonomic spray gun and 5 Quick-Connect nozzles. This mobile system brings a cleaning solution into the field where water supply is an issue. This powerful SIMPSON mobile pressure washing system will handle all your commercial jobs. It is perfectly suited for contract cleaners, mobile detailers, municipalities and resorts. The trailer is dot certified as an over-the-road pressure washer system. Job-Site set-up is a snap. Pull up to the work area, connect the spray gun, start the engine and begin cleaning. Warranty Details: Engine - 3 Year Limited Commercial Warranty | Pump - 5 Year Limited Warranty | Frame - 1 Year Limited Warranty -

Out of stock

-

Sale!

- Motor: 2 HP

- Cutting capacity - rectangular: 9-1/2 in.

- Cutting capacity - round: 10 in.

- Blade speeds: 98 - 394 FPM

- Blade length: 132 in.

- Head type: Swivel

- Footprint: 28-1/2 in. x 45 in.

- Overall height: 58 in.

- Shipping weight: 967 lbs.

-

Out of stock

This T1242 30-Ton Electric/Hydraulic Shop Press features a 3 HP, 220V, single-phase hydraulic pump motor, horizontally adjustable sliding piston head, easy-access push-button controls, 10" stroke, and table-to-piston distance of 7-3/4" to 39". Includes carriage/table lifting chain, two table plates, and a full-size rear guard plate.

This T1242 30-Ton Electric/Hydraulic Shop Press features a 3 HP, 220V, single-phase hydraulic pump motor, horizontally adjustable sliding piston head, easy-access push-button controls, 10" stroke, and table-to-piston distance of 7-3/4" to 39". Includes carriage/table lifting chain, two table plates, and a full-size rear guard plate. -

Out of stock

At Powermatic, we believe that ambition is the fuel that drives progress. Every product we engineer is born out of the same idea: How can we empower woodworkers to do more? In shops across the world, craftsmen are continually pushing the limits of their creativity, and in turn, challenging us to provide the best tools for the job. When we reimagined our line of bandsaws, we not only set out to meet their ambitions, but to exceed them. Larger projects and larger workpieces call for more power, more resaw capacity and more cast iron. This bandsaw also features the legendary quality, precision and attention to detail that has been helping woodworkers expand their ambition for more than ninety years.

At Powermatic, we believe that ambition is the fuel that drives progress. Every product we engineer is born out of the same idea: How can we empower woodworkers to do more? In shops across the world, craftsmen are continually pushing the limits of their creativity, and in turn, challenging us to provide the best tools for the job. When we reimagined our line of bandsaws, we not only set out to meet their ambitions, but to exceed them. Larger projects and larger workpieces call for more power, more resaw capacity and more cast iron. This bandsaw also features the legendary quality, precision and attention to detail that has been helping woodworkers expand their ambition for more than ninety years. -

Out of stock

The PM3000B brings heavyweight performance and patented innovations to the 14-inch table saw arena. The riving knife rises and lowers with the blade, substantially reducing kickback risk; and both riving knife and blade guard each have a quick-release, so mounting and removing them is fast and tool-free. A wide-stance trunnion and concave teeth on the trunnion gears promote smooth blade raising/tilting. The Poly-V drive belt system results in quieter, more efficient power transfer with virtually no vibration and less heat build-up. A newly designed push button arbor lock is accessible from above the table top and eliminates the need for dual arbor wrenches. Sloped cabinet floor, dust shroud around the blade, and built-in port for dust extraction. Style (Type)Cabinet Blade Diameter (In.)14 Arbor Diameter (In.)1 Arbor Speed (RPM)4500 Maximum Depth of Cut at 90 Degrees (In.)5-1/8 Maximum Depth of Cut at 45 Degrees (In.)3-1/2 Maximum Diameter of Dado (In.)8 Maximum Width of Dado (In.)13/16 Table in Front of Saw Blade at Maximum Depth of Cut (In.)15-1/2 Maximum Rip Right of Blade (In.)50 Maximum Rip Left of Blade (In.)14 Table TypeCast Iron Table Height from Floor (In.)35-1/4 Table Size (In.)26 x 38 Table Size with Extensions (In.)48 x 38 Table T-Slot (In.)3/4 x 3/8 Dust Collection Minimum CFM Required (CFM)600 Dust Port Outside Diameter (In.)4 Motor Voltage (V.)230/460 Prewired Voltage (V.)230 Motor Current (Amps)18.4/9.2 Recommended Circuit Size (Amps.)30

The PM3000B brings heavyweight performance and patented innovations to the 14-inch table saw arena. The riving knife rises and lowers with the blade, substantially reducing kickback risk; and both riving knife and blade guard each have a quick-release, so mounting and removing them is fast and tool-free. A wide-stance trunnion and concave teeth on the trunnion gears promote smooth blade raising/tilting. The Poly-V drive belt system results in quieter, more efficient power transfer with virtually no vibration and less heat build-up. A newly designed push button arbor lock is accessible from above the table top and eliminates the need for dual arbor wrenches. Sloped cabinet floor, dust shroud around the blade, and built-in port for dust extraction. Style (Type)Cabinet Blade Diameter (In.)14 Arbor Diameter (In.)1 Arbor Speed (RPM)4500 Maximum Depth of Cut at 90 Degrees (In.)5-1/8 Maximum Depth of Cut at 45 Degrees (In.)3-1/2 Maximum Diameter of Dado (In.)8 Maximum Width of Dado (In.)13/16 Table in Front of Saw Blade at Maximum Depth of Cut (In.)15-1/2 Maximum Rip Right of Blade (In.)50 Maximum Rip Left of Blade (In.)14 Table TypeCast Iron Table Height from Floor (In.)35-1/4 Table Size (In.)26 x 38 Table Size with Extensions (In.)48 x 38 Table T-Slot (In.)3/4 x 3/8 Dust Collection Minimum CFM Required (CFM)600 Dust Port Outside Diameter (In.)4 Motor Voltage (V.)230/460 Prewired Voltage (V.)230 Motor Current (Amps)18.4/9.2 Recommended Circuit Size (Amps.)30 -

Grizzly G0901 28" Portable Sawmill

Buy now to lock in the sale price! Orders won’t ship until Spring 2021

Mill your own lumber right off your property!

The all-new Grizzly G0901 28" Portable Sawmill is designed for quick setup with a rock-solid, 12-foot steel track with adjustable feet capable of leveling on just about any surface. The track is modular, allowing you to easily attach and level additional 6-foot-long sections in order to mill practically any length of lumber you need. The cut thickness is set in 1/16" intervals with the locking hand crank and the sturdy 4-column saw carriage moves smoothly along the track on ball-bearing rollers. Two adjustable work stops hold the log in place, while a manually adjusted workpiece clamp prevents movement during cuts. Our engineers worked hard to create the ultimate sawmill with the capacity and solid performance needed to get the job done right in the field! The G0901 28" Portable Sawmill comes with a one-year warranty which covers replacement parts. The product is supported by a US-based support team and parts are available online and shipped from our massive parts department in Springfield, MO. FEATURES:- Modular track system for varying length requirements

- Hand throttle allows easy blade speed control during the cut

- Locking hand crank with detents for quickly setting cut thickness in 1/16" increments

- Ball-bearing rollers provide smooth movement of saw carriage along track

- Leveling feet for stabilizing saw mill on uneven ground surface

- Adjustable work stops and clamp for holding log in place during cut

- Onboard water reservoir with drip nozzle for blade lubrication

- Gas engine: 13-1/2 HP Briggs and Stratton®

- Included track length: 144"

- Maximum log diameter: 28"

- Maximum cut width: 22"

- Maximum cut thickness: 6"

- Blade size: 1" x 144"

- Wheel diameter: 19"

- Footprint: 35" x 144"

- Overall dimensions: 75" W x 144" L x 56" H

-

Sand stock up to 36-1/2" wide and 4" thick with variable speed feed control and the economy of spiral-wrapped 6" wide sandpaper rolls. Built for production environments, these Drum Sanders feature industrial-quality conveyor belts and dual 6" sanding drums. Includes a 4-port dust scoop to maximize dust collection, easy access to sanding drums, emergency stop for safety, solid steel construction, independent motor control, amp load meter, and massive power with a 10 HP, single-phase motor. With the variable-speed control on the conveyor, you can dial in the perfect finish you need for each job. CSA certified meeting CSA C22.2 #105-1953 and UL 987-8 standards!

Sand stock up to 36-1/2" wide and 4" thick with variable speed feed control and the economy of spiral-wrapped 6" wide sandpaper rolls. Built for production environments, these Drum Sanders feature industrial-quality conveyor belts and dual 6" sanding drums. Includes a 4-port dust scoop to maximize dust collection, easy access to sanding drums, emergency stop for safety, solid steel construction, independent motor control, amp load meter, and massive power with a 10 HP, single-phase motor. With the variable-speed control on the conveyor, you can dial in the perfect finish you need for each job. CSA certified meeting CSA C22.2 #105-1953 and UL 987-8 standards! -

Out of stock

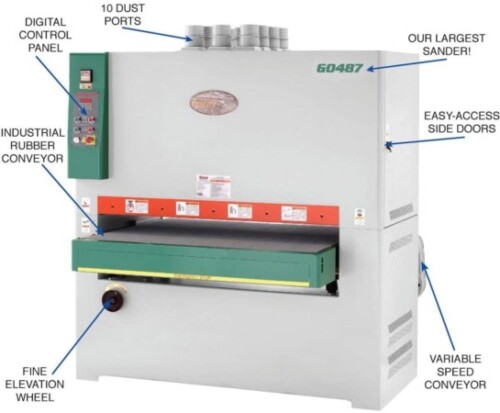

- Built for industrial 8-hour shifts.

- Massive 37”-wide and 6”-high maximum capacity.

- Thickness sander with a minimum of ⅛” allows you to tackle a wide range of projects.

- 7.5 hp motor drives 2 steel drums.

- Hard durometer rubber coating on drums ensures a flat, mar-free finish.

- Independently adjustable rear drum makes fine-tuning easy.

- Cast iron table incorporates 4 solid jackscrews.

- Conveyor belt provides a great grip on your material.

- ¼ hp variable-speed feed motor lets you adjust between 3.7 and 14.2 surface feet per minute.

- DRO shows the thickness of your material, so you can reach the exact result you want.

- Dual drums allow you to use 2 different grits at once—first to take off thickness, then to smooth out the finish.

- Quick clamp changeover system for attaching sanding paper to your drums saves you time and effort.

- Our large sander's thick steel base prevents vibrations. Most other companies’ machines are not so heavily and rigidly built.

- Cabinet in the base provides a great place to store your extra belts.

- 2 dust ports can hook up to your dust collector and help maintain high air quality in your shop.

- Large orange safety brake lets you immediately stop the machine when necessary.

- Covered by a 1-year parts warranty.

- Replacement drum sander parts are in stock at our Wisconsin headquarters, so we can get them to you quickly.

- We include lifetime technical support by phone from a team of reps with hands-on machine experience.

-

Sale!

This 3 sided, heavy-duty shaper will pay for itself quickly in cabinet and production shops that normally require several shapers or time consuming cutter changes. The combinations of cutters and set-ups you can utilize on this machine are endless.

This 3 sided, heavy-duty shaper will pay for itself quickly in cabinet and production shops that normally require several shapers or time consuming cutter changes. The combinations of cutters and set-ups you can utilize on this machine are endless. -

G0709 14" x 40" Gunsmithing Gearhead Lathe

An accurate and powerful lathe.

What makes the G0709 14" x 40" Gunsmithing Gearhead Lathe a "gunsmithing" lathe is that it comes with features typically not found on standard lathes, such as the high-precision NSK bearings, extra-large 1-9/16" spindle bore and a "spider" mount system. The spider mount system has four brass-tipped screws that stabilize long shafting and rifle barrels through the outboard end of the spindle. Supplied with a 2 HP motor, the 8-speed gearhead of the G0709 produces spindle speeds from 70-2000 RPM. The tailstock lock system features a drive hub, which allows you to use a 1/2” torque wrench to clamp the tailstock in place at a pre-determined torque setting. This ensures consistent draw-down alignment every time, even with multiple lathe operators using the machine. The G0709 features a foot brake that also acts as a safety device and can bring the machine to an instant stop. The G0709 also comes with a D1-5 spindle, a 200 series quick change tool post, flood coolant system, LED work light, and a pull-out chip tray. Like all Grizzly gunsmithing lathes, the G0709 comes with a 1-year warranty covering parts and assuring the unit is free from factory defects. (Consumables are not covered by the warranty.) The G0709 manual was written by our U.S. based Documentation Department and is packed with useful information. The complete and easy to read manual makes it easier to assemble and maintain your lathe. The Grizzly Technical Support team is U.S. based. Parts and accessories for the lathe may be available online and shipped from the Grizzly parts warehouse in Springfield, MO.SPECIFICATIONS

- Motor: 2 HP, 220V, single-phase, 10A

- Swing over bed: 14"

- Distance between centers: 40"

- Swing over saddle: 13-13/16"

- Swing over cross slide: 8-13/16"

- Spindle bore: 1.57" (40mm)

- Spindle nose taper: MT#5

- Spindle nose: D1-5 Camlock

- Spindle speeds: 8, 70-2000 RPM

- Carriage travel: 36"

- Cross slide travel: 6-11/16"

- Tailstock barrel taper: MT#3

- Tailstock barrel travel: 3-15/16"

- Overall dimensions: 71-1/2" L x 26-3/16" W x 52" H

- Approximate shipping weight: 1550 lbs.

FEATURES

- Easy-to-use lever controls

- Hardened and ground cast-iron bed

- Cuts 4-112 Standard TPI and 0.1-7 Metric

- Cuts LH threads

- On/off reverse switch on carriage

- Socket for tailstock lock

- Cast aluminum gear cover

STANDARD EQUIPMENT

- 6" 3-Jaw chuck with reversible jaws

- 8" 4-Jaw chuck with independent jaws

- 11" face plate

- Steady rest/follow rest

- Full length splash guard

- Quick change tool post with 2 tool holders

- (2) MT#3 dead centers (1 carbide tipped)

- (1) MT#3 live center

- (1) MT#5 - MT#3 sleeve

- Pull out chip pan

- 1/2" drill chuck w/ MT#3 arbor

- Toolbox

-

-

Out of stock

-

Out of stock

- Adjustable Hydraulic Downfeed: Control is easily adjusted to enable feed rates to evolve with variable materials.

- Magnetic Starter: Low voltage and lost phase protection.

- Added Safety: Automatic blade breakage sensor detects accidental breakage and interrupts the power.

- Extended Blade Life: Steel plate base contains a 4-gallon coolant system.

- Easy Clean Up: Integrated pressurized wash hose.

- Self-Propelled Blade Brush: Prevents chip build up in the blade guides.

- CSA/CUS Certified: This machine follows strict guidelines and electrical requirements.

-

Ironworker Max Force (Tons) 50 Oil Capacity (Gal.) 7 Speed (Strokes/Minute) 23 Throat Depth (In.) 7-1/2 5 Motor HP Hydraulic Pressure (PSI) 2500 Voltage 230 1 Phase 23 Amps Punching Station Pedestal Die Table Flat Bar Shear Angle Shear Universal Open Tooling Station Metalworking

Ironworker Max Force (Tons) 50 Oil Capacity (Gal.) 7 Speed (Strokes/Minute) 23 Throat Depth (In.) 7-1/2 5 Motor HP Hydraulic Pressure (PSI) 2500 Voltage 230 1 Phase 23 Amps Punching Station Pedestal Die Table Flat Bar Shear Angle Shear Universal Open Tooling Station Metalworking -

Ironworker Max Force (Tons) 62 Oil Capacity (Gal.) 7 Speed (Strokes/Minute) 23 Throat Depth (In.) 8-7/8 5 Motor HP Hydraulic Pressure (PSI) 2500 Voltage 230 3 Phase 14 Amps Punching Station Pedestal Die Table 14 in Wide Flat Bar Shear Angle Shear Coper Notcher Metalworking

Ironworker Max Force (Tons) 62 Oil Capacity (Gal.) 7 Speed (Strokes/Minute) 23 Throat Depth (In.) 8-7/8 5 Motor HP Hydraulic Pressure (PSI) 2500 Voltage 230 3 Phase 14 Amps Punching Station Pedestal Die Table 14 in Wide Flat Bar Shear Angle Shear Coper Notcher Metalworking -

Out of stock

10 Horsepower 3-Phase 24" Wide Belt Wood Sander with Pneumatic Oscillation Control

These machines were developed in collaboration with James Goodall, a famous luthier, who wanted a machine that could sand very short and very thin pieces. This collaboration resulted in the introduction of the G9962Z & G9962ZX, which have become the "staple" of the guitar building industry. The main features that enable these sanders to process short pieces efficiently are the single drum and double infeed and outfeed pressure rollers positioned close to the drum. The result is a continuous downward pressure on extremely thin stock as short as 9", which is the distance between the first infeed and first outfeed pressure rollers. The feed belt is made of hard rubber to prevent distortion of thin stock while sanding. Features include digital read out, powered table elevation, variable speed conveyor, disc brake stopping system, pneumatic belt tracking, pneumatic belt oscillation, and separate motors for the drum, feed rollers, and table elevation. -

G0603X 25" 15 HP 3-Phase Extreme Duty Planer w/ Helical Cutterhead

Precision planing with digital control.

The G0603X 25" 3-Phase Extreme Duty Planer has an incredible 15 HP motor to make quick work of those big planing jobs. The G0603X features a unique helical cutterhead with 170 inserts rotated at 15° for smooth shearing cuts - meaning you can say goodbye to tear-out - while having an ultra-quiet machine and a smoother finish. The digital controls to allow you to simply enter the thickness of the board you want or the amount you want to remove, which saves time and reduces waste. All controls are conveniently located. The segmented chip breaker leads directly into the dust hood with a 5” dust port to help ensure the work area stays as clear as possible. And because it's a Grizzly Extreme Series®, you can be assured that your machine will provide years of reliable service. Like all Grizzly planers, the G0603X comes with a 1-year warranty which covers parts and assures the unit is free from factory defects. (Consumables are not covered by the warranty.) The G0603X manual was written by our U.S. based Technical Documentation Department and is packed with useful information. The Grizzly Customer Service and Technical Support Teams are U.S. based. Parts and accessories for the planer are available on-line and shipped from the Grizzly parts warehouse in Springfield, MO. Made in an ISO 9001 factory SPECIFICATIONS:- Cutterhead motor: 15 HP, 220V/440V*, 3-phase, 37A/18.5A

- Table elevation motor: 1/2 HP, TEFC, 2.4A/1.2A

- Table size: 25" W x 57" L

- Maximum cutting width: 25"

- Maximum stock thickness: 9"

- Maximum cutting depth: 1/4"

- Minimum stock thickness: 1/4"

- Minimum stock length: 10"

- Feed rate: 20, 25 & 30 FPM

- Cutterhead: 6-row helical, 170 inserts

- Cutterhead speed: 4900 RPM

- Power transfer: Triple V-belt

- Overall size with infeed/outfeed tables: 60-1/4"H x 57-3/8"W x 54-3/8"D

- Approximate shipping weight: 2054 lbs.

- Segmented chip breaker

- Precision-ground cast-iron table

- 5" dust port

- Micro-adjustable table height

- Infeed roller is serrated steel

- Outfeed roller is finely finished steel

- Digitally controlled table elevation for extreme accuracy

- Adjustable bed rollers

- Easy access cutterhead

- 3-Speed (20,25,30) feed Rate

- Inch/metric readout

- Emergency stop button*This machine is prewired for 220V. We can rewire to 440V in a few days’ time for a fee of $250. Please contact Grizzly Technical Support at (570)546-9663 before placing your order.

-

Out of stock

The Grizzly Industrial G0445-24" 10 HP 3-Phase Platen Type Wide-Belt Sander machine was developed in collaboration with James Goodall, a famous luthier, who wanted a machine that could sand very short and very thin pieces. The main features that enable it to process short pieces efficiently are the single drum and the double infeed and double outfeed pressure rollers that are tucked in closer to the drum. The result is that you have continuous downward pressure on extremely thin stock as short as 14" (G0582). That is the distance between the first infeed and first outfeed pressure rollers. The feed belt is made of harder rubber to prevent distortion of thin stock while sanding. The new platen model will sand stock as short as 9" (G0445). All of these models include features like digital read out, powered table elevation, four screw jacks for table support, variable speed, disc brake stopping system, dust proof photo electric eye/pneumatic control for belt oscillation, and separate motors for the drum, the feed rollers, and the table elevation.

The Grizzly Industrial G0445-24" 10 HP 3-Phase Platen Type Wide-Belt Sander machine was developed in collaboration with James Goodall, a famous luthier, who wanted a machine that could sand very short and very thin pieces. The main features that enable it to process short pieces efficiently are the single drum and the double infeed and double outfeed pressure rollers that are tucked in closer to the drum. The result is that you have continuous downward pressure on extremely thin stock as short as 14" (G0582). That is the distance between the first infeed and first outfeed pressure rollers. The feed belt is made of harder rubber to prevent distortion of thin stock while sanding. The new platen model will sand stock as short as 9" (G0445). All of these models include features like digital read out, powered table elevation, four screw jacks for table support, variable speed, disc brake stopping system, dust proof photo electric eye/pneumatic control for belt oscillation, and separate motors for the drum, the feed rollers, and the table elevation. -

Out of stock

Features:

- Pneumatic Belt Tensioning

- Digital Readout and Elevation Controls Accurate to 0.005"

- Powered Table Elevation with Keypad for Typing/Storing Exact Measurements

- Industrial Rubber Conveyor Belt

- Micro-Adjustable Graphite/Felt Platen (Rear Drum)

- Variable Feed Speeds

- Disc Brake for Emergency Stops

- Independent Motor Controls for Sanding Drums, Table Elevation and Conveyor