-

This M1111 Milling Machine has all of the important features of the M1110, but with a few extra time-saving luxuries. However, this mill is further fortified with a quick-tilt headstock for horizontal milling, 1 HP brushless motor, a multi-function digital depth scale on the quill, push-button speed control and digital spindle tachometer. The back-lit digital tachometer tells you the precise spindle speed for matching tooling and material. All of these extra features make the M1111 Milling Machine one of the most sought after machines available.

This M1111 Milling Machine has all of the important features of the M1110, but with a few extra time-saving luxuries. However, this mill is further fortified with a quick-tilt headstock for horizontal milling, 1 HP brushless motor, a multi-function digital depth scale on the quill, push-button speed control and digital spindle tachometer. The back-lit digital tachometer tells you the precise spindle speed for matching tooling and material. All of these extra features make the M1111 Milling Machine one of the most sought after machines available. -

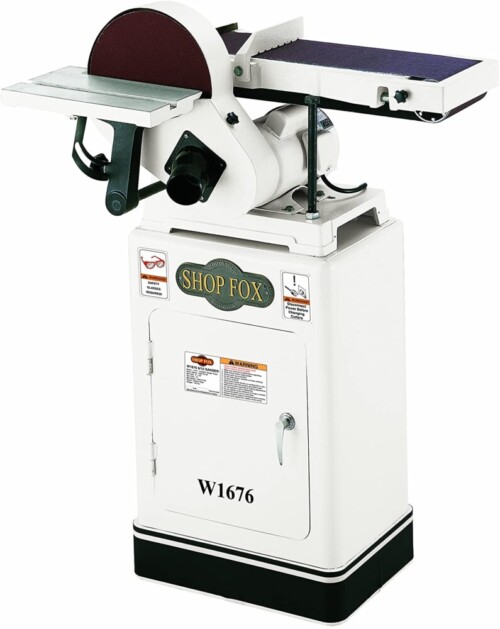

This combination 6" x 48" Belt and 10" Disc Sander bridges the large gap between the bench-top models and the more expensive industrial models. Our 1 HP motor offers plenty of torque for all your sanding operations and the weight of the heavy cast iron construction and full cabinet stand keeps vibration in check while offering a very attractive package. The cabinet is 100% usable for storage to help take away shop clutter. This will be a proud addition to your shop and still leaves plenty of funds left over for other shop tools.

This combination 6" x 48" Belt and 10" Disc Sander bridges the large gap between the bench-top models and the more expensive industrial models. Our 1 HP motor offers plenty of torque for all your sanding operations and the weight of the heavy cast iron construction and full cabinet stand keeps vibration in check while offering a very attractive package. The cabinet is 100% usable for storage to help take away shop clutter. This will be a proud addition to your shop and still leaves plenty of funds left over for other shop tools. -

-

New model includes: Sanding Head Assembly with Flatter Installed, Conveyor Table Assembly, An Aluminum Drum w/ Two Bearing Sets, A Coupling and one 80 Girt Abrasive Belt, Open Stand Assembly.

Drum sanding with Intellisand technology.

- Eliminates the guess-work of manually controlling the infinitely-variable feed speed

- Simplifies the sanding operation

- Provides a consistent finish even with varying grain pattern and density

- Greatly increases abrasive planning and dimensioning speed

- Maintains highest possible feed rate without overload

19-38” Combo Drum/Brush Sander

- True combo machine: Drum and Flat stock. Change sanding heads and sand contoured shapes

- Brush Applications include but are not limited to: white wood sanding, de-nibbing, sealer sanding, primer sanding, UV roughing, metal graining/straight lining, metal de-burring, sanding/polishing solid surface material, scuff sanding, shutter sanding, de-glossing and distressing

- Bench-top unit, standard with 180 Grit Flatter sanding head

- AC Inverter – Variable Head Speed, 200-1800 RPM

- Tension rollers are adjustable in height, span, and hold down pressure

- Heavy-duty cast iron construction for strength, rigidity, and reduced vibration

- Preset “fast” control to adjust for 38” use

Download ManualSpecifications:

Warranty: Two years on parts and labor, limited; Manufacturer’s warranties on conveyor belts, brush heads and abrasives.

Sanding Capacity:

Maximum Width: 38” (two passes)

Minimum Length: 2-1/4” to 3-1/2” (varies with application)

Maximum Thickness: 4” typical (varies with brush/drum style & application)

Minimum Thickness: 1/32” typical (varies with applications)

Dimensions:

Length – 36”

Width – 42”

Height – 24” without stand

Brush: 5” diameter typical

Typical bristle length: 1-1/2” (varies)

Brush Speed:

Infinitely variable 200 to 1000 RPM

Brush 1750 RPM

Drum Dust Hood: Hinged back with 4” vacuum port

Height Adjustment: 1/16” per revolution, Depth Gauge included Conveyor

Motor: 43”–lb. torque Direct drive D.C. motor Infinitely variable 0–10 feet-per-minute

Drive Motor (TEFC): 1-3/4 HP Continuous-duty

Power Requirements: 110 Volt, Single Phase 20 amp service

Shipping Weight: 242lbs. (weight varies on how equipped) 2 boxes

-

-

This 37-inch sander has what it takes to get those big jobs done - fast. Sand panels and boards up to 4-inch thick and 36-1/2-inch wide with the dual 6-inch sanding drums. The feed speed is adjustable from 6 to 18 FPM so you can fine-tune your production speed to provide the desired finish. The variable speed knob and amp meter make it easy to monitor workpiece load. Other great features: a hinged hood, an emergency stop bar, pedestal-mounted controls, four 4-inch dust ports, and a 15 HP 220V/440V* single-phase motor.

This 37-inch sander has what it takes to get those big jobs done - fast. Sand panels and boards up to 4-inch thick and 36-1/2-inch wide with the dual 6-inch sanding drums. The feed speed is adjustable from 6 to 18 FPM so you can fine-tune your production speed to provide the desired finish. The variable speed knob and amp meter make it easy to monitor workpiece load. Other great features: a hinged hood, an emergency stop bar, pedestal-mounted controls, four 4-inch dust ports, and a 15 HP 220V/440V* single-phase motor. -

Out of stock

Description

Numeric control pad and digital readout provide the ultimate in precision. Other features include quick-change belt system with automatic belt tensioning, air-controlled automatic belt tracking system, motorized table elevation control, adjustable air-controlled belt oscillation system, and load meter. Certified to CSA and UL standards.Specifications

- Sanding motor: 10 HP, 220V, single-phase, 1725 RPM, 50A

- Feed motor: 1 HP, 220V, single-phase, 1725 RPM, 7A

- Elevation motor: 1/3 HP, 220V, single-phase, 1725 RPM, 3A

- Drum speed: 3550 FPM

- Drum diameter: 8"

- Feed rate: variable, 15–49 FPM

- Max. stock width: 24"

- Max. stock thickness: 6"

- Min. stock thickness: 1/8"

- Required air pressure: 75 PSI @ 7 CFM

- Sanding belt size: 25" x 60"

- Dust port: (2) 4"

- Emergency stop bar with brake

- Manual and motorized table elevation control

- Sanding load meter

- Digital readout and controls

- Made in an ISO 9001 factory

- Footprint: 39-1/4"W x 19-1/4"D

- Height with dust ports: 71"

- CSA certified meeting CSA C22.2 #105–1953 and UL 987–7 standards

- Approximate shipping weight: 1870 lbs.

California Proposition 65 Warning

-

Shop Fox® Heavy Duty Mobile Bases are designed to give you a stable and mobile platform upon which to mount machinery and equipment having a variety of base sizes and weights. The heavy-duty casters are arranged on outriggers allowing the machine to sit as low as possible and yet be extremely stable. Swivel casters on two corners provide excellent maneuverability. The bolt pattern on the fixed caster side allows orientation of the wheels in either of two directions. The base can be assembled in any of eight configurations providing maximum flexibility of use. The unique two piece retractable feet use rare earth magnets to allow the knob to turn while the foot pad is tight to the floor. You will find these mobile bases to be far superior to any mobile base on the market in strength, adjustability and movability. This patented mobile base is the most stable on the market with outrigger type supports. Adjusts from 10-1/2" x 14-1/2" to 17-1/2" x 21-1/2". 600 lb. maximum capacity.

Shop Fox® Heavy Duty Mobile Bases are designed to give you a stable and mobile platform upon which to mount machinery and equipment having a variety of base sizes and weights. The heavy-duty casters are arranged on outriggers allowing the machine to sit as low as possible and yet be extremely stable. Swivel casters on two corners provide excellent maneuverability. The bolt pattern on the fixed caster side allows orientation of the wheels in either of two directions. The base can be assembled in any of eight configurations providing maximum flexibility of use. The unique two piece retractable feet use rare earth magnets to allow the knob to turn while the foot pad is tight to the floor. You will find these mobile bases to be far superior to any mobile base on the market in strength, adjustability and movability. This patented mobile base is the most stable on the market with outrigger type supports. Adjusts from 10-1/2" x 14-1/2" to 17-1/2" x 21-1/2". 600 lb. maximum capacity. -

Features such as extruded-aluminum fence and rails, quick-release blade tension, miter gauge, upper and lower ball bearing blade guides, enclosed cabinet stand, hinged wheel covers, 4" dust port, and a 1 HP motor are all standard. And, with its cast -iron frame and table, this bandsaw will be a reliable shop fixture for many years to come. An optional 6" extension block kit (D3348) is also available. CSA certified meeting CSA and UL standards!California Proposition 65 Warning

Features such as extruded-aluminum fence and rails, quick-release blade tension, miter gauge, upper and lower ball bearing blade guides, enclosed cabinet stand, hinged wheel covers, 4" dust port, and a 1 HP motor are all standard. And, with its cast -iron frame and table, this bandsaw will be a reliable shop fixture for many years to come. An optional 6" extension block kit (D3348) is also available. CSA certified meeting CSA and UL standards!California Proposition 65 WarningSpecifications

- Motor: 1 HP, 110V/220V, prewired 110V, single-phase, TEFC, 1725 RPM, 11A/5.5A

- Blade size: 93-1/2" (1/8" to 3/4" wide)

- Precision-ground cast-iron table size: 14" x 14" x 1-1/2"

- Cutting capacity (throat): 13-1/2"

- Max. cutting height: 6"

- Table height above floor: 43"

- Blade speeds: 1800 & 3100 FPM

- Cast-iron frame and wheels

- Table tilt: 45° right, 10° left

- Precision-ground cast-iron table

- Cast-iron blade wheels

- Deluxe extruded-aluminum fence

- Ball-bearing blade guides

- Footprint: 18"W x 15-1/2"D

- Heavy-duty cabinet-type stand with storage space

- Quick-change blade release/tensioning

- Upper and lower ball bearing blade guides

- All ball bearing construction

- 4" dust port

- Includes one 3/8" blade, fence and miter gauge

- Fence scale with magnifying window

- Approximate shipping weight: 275 lbs.

-

-

Out of stock

-

With 12" wide capacity and three sheet metal functions in one unit, there is no need to spend extra money and tie up shop space with three single-use machines. You'll love the convenience and accuracy of these do it all machines!

With 12" wide capacity and three sheet metal functions in one unit, there is no need to spend extra money and tie up shop space with three single-use machines. You'll love the convenience and accuracy of these do it all machines!Specifications

- Maximum capacity in mild steel: 22-gauge

- Roll diameter: 1-1/2"

- Approximate shipping weight: 116 lbs.

-

Out of stock

This 8" Parallelogram Jointer features extra-long infeed and outfeed tables that can be adjusted transversely and longitudinally to each other for ultra-precision face flattening and edge jointing. Table levers with positive table locks provide quick and precise height adjustments, and the pedestal-mounted power switch is conveniently located for easy on and easy off. This version features a straight knife cutterhead.

This 8" Parallelogram Jointer features extra-long infeed and outfeed tables that can be adjusted transversely and longitudinally to each other for ultra-precision face flattening and edge jointing. Table levers with positive table locks provide quick and precise height adjustments, and the pedestal-mounted power switch is conveniently located for easy on and easy off. This version features a straight knife cutterhead. -

Perfect for cutting wide panels in limited shop space, this 10" Sliding Table Saw features a scoring blade to eliminate cross grain tear-out, a 63" long crosscut capacity, telescoping crosscut fence with two rock-solid flip stops, fully-adjustable miter fence with its own flip stop, two-position extruded-aluminum rip fence, riving knife, and large blade guard with integral dust port. This 10" Sliding Table Saw makes quick work of all standard plywood panels. Accepts 10" saw blades with 5/8" arbor bores or dado blades up to 13/16" wide. Certified to CSA standards!

Perfect for cutting wide panels in limited shop space, this 10" Sliding Table Saw features a scoring blade to eliminate cross grain tear-out, a 63" long crosscut capacity, telescoping crosscut fence with two rock-solid flip stops, fully-adjustable miter fence with its own flip stop, two-position extruded-aluminum rip fence, riving knife, and large blade guard with integral dust port. This 10" Sliding Table Saw makes quick work of all standard plywood panels. Accepts 10" saw blades with 5/8" arbor bores or dado blades up to 13/16" wide. Certified to CSA standards!