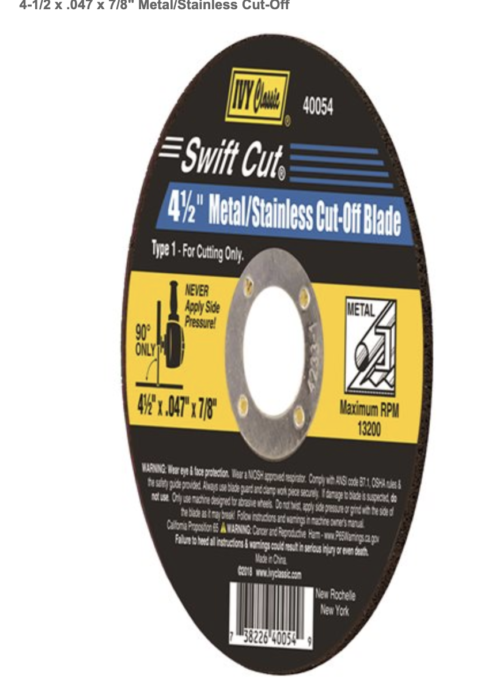

- Type 1 - For Cutting Only

- Designed to cut stainless steel, angle iron, sheet metal and other ferrous metal products, Swift Cut (Registered Trademark)

- Resin bonded Aluminum-Oxide grain for faster cutting, Type 1 blade - for cutting only

- Blade double reinforced with fiberglass mesh for durability and safety

- Arbor reinforced with metal for extra strength

- Diameter: 4-1/2-inch, Width: 0.047-inch, Arbor: 5/8-inch, Max RPM: 13,200

-

Metal/Stainless Steel Thin Cut-Off Blades - Swift Cut® Abrasive You are purchasing one five back.

Metal/Stainless Steel Thin Cut-Off Blades - Swift Cut® Abrasive You are purchasing one five back. -

Out of stock

Jet Dust Collection Box

$159.99The Dust Collection Box offers the user greater dust containment and dust collection when routing. The all metal construction with integrated air flow vents offer greater efficiency and durability. The Dust Collection Box comes standard with a 4” dust port. -

Out of stock

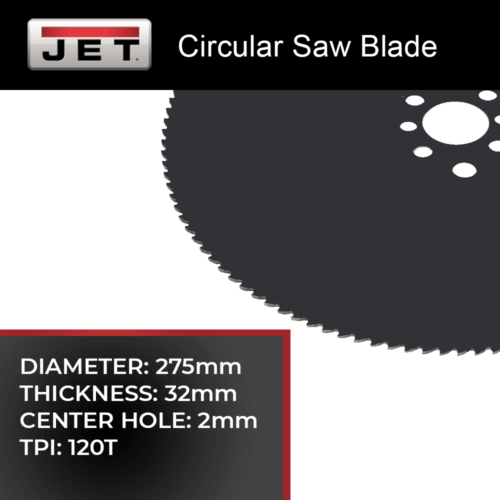

Saw blade for JET CS-275 Manual Cold Saw. Trust this authentic OEM part. See model diagram and owner's manual for installation details and precautions which should be taken. One blade.

Saw blade for JET CS-275 Manual Cold Saw. Trust this authentic OEM part. See model diagram and owner's manual for installation details and precautions which should be taken. One blade. -

Out of stock

Jet 756041 SBR-40M Shear Brake and Roll JET innovation allows machine shop professionals the ability to perform several vital tasks with a single compact machine. The Combination Shear, Brake and Roll handles the jobs of three separate machines, adding tremendous versatility to your metal forming operation, without crowding the shop floor. This high-quality triple threat is backed by the JET industry leading Two Year Warranty. Features:

Jet 756041 SBR-40M Shear Brake and Roll JET innovation allows machine shop professionals the ability to perform several vital tasks with a single compact machine. The Combination Shear, Brake and Roll handles the jobs of three separate machines, adding tremendous versatility to your metal forming operation, without crowding the shop floor. This high-quality triple threat is backed by the JET industry leading Two Year Warranty. Features:- Combination shear, brake and roll in one compact machine

- Right or left hand operation

- Shear can be used for mild steel, aluminum, brass, copper, lead, plastic and zinc

- Brake is equipped with easily removable fingers that permit angle, channel, box and other complex bending operations

- Slip rolls are precision turned and ground with wire grooves

- Spring-loaded work hold down

- Back gauge

- Dual edge shear blade

- Style (Type) Combination

- Mild Steel Capacity (Gauge) 20

- Shearing Capacity (Gauge) 20

- Bending Capacity (Gauge) 20

- Rolling Capacity (Gauge) 20

- Size of Slip Roll (L x Dia.) (In.) 40 x 1-5/8

- Width of Upper Dies (In.) 1, 2, 2, 4, 6, 7,8, 12

- Upper Die Height (In.) 4-3/4

- Minimum Forming Radius (In.) 1

- Wire Grooves (In.) 1/8, 3/16, 1/4

- Base Dimensions (L x W x H) (In.) 16-1/2 x 43

- Overall Dimensions (L x W x H) (In.) 56 x 23 x 30

- Weight (Lbs.) 575

-

Out of stock

JET Coldsaws deliver clean, burr-free cuts and offer machine shop and fabrication professionals a list of features and standard design characteristics that you’ve come to expect from JET. All backed by the industry leading full service Two Year Warranty

JET Coldsaws deliver clean, burr-free cuts and offer machine shop and fabrication professionals a list of features and standard design characteristics that you’ve come to expect from JET. All backed by the industry leading full service Two Year Warranty -

Out of stock

Mill drills are a lighter alternative to a milling machine. These combine a belt driven drill press with the dual coordinate abilities of the milling machine's table for flexibility and efficiency. A locking collet prevents the cutting tool from falling away from the spindle when lateral forces are experienced against the bit. Although light in construction, the JMD Milling Drilling Machines possess the advantages of space-saving versatility, affordability and light machining capability. Optional base available. stk number 350045

Mill drills are a lighter alternative to a milling machine. These combine a belt driven drill press with the dual coordinate abilities of the milling machine's table for flexibility and efficiency. A locking collet prevents the cutting tool from falling away from the spindle when lateral forces are experienced against the bit. Although light in construction, the JMD Milling Drilling Machines possess the advantages of space-saving versatility, affordability and light machining capability. Optional base available. stk number 350045 -

Out of stock

Jet 350020 JMD-18PFN Milling/Drilling Machine W/Power Downfeed, 2HP, 115V, 1-Phase Mill drills are a lighter alternative to a Milling machine. These combine a belt driven drill press with the dual coordinate abilities of the Milling machine's table for flexibility and efficiency. A locking collet prevents the cutting tool from falling away from the spindle when lateral forces are experienced against the bit. Although light in construction, the JMD Milling Drilling Machines possess the advantages of space-saving versatility, affordability and light machining capability. Features:

Jet 350020 JMD-18PFN Milling/Drilling Machine W/Power Downfeed, 2HP, 115V, 1-Phase Mill drills are a lighter alternative to a Milling machine. These combine a belt driven drill press with the dual coordinate abilities of the Milling machine's table for flexibility and efficiency. A locking collet prevents the cutting tool from falling away from the spindle when lateral forces are experienced against the bit. Although light in construction, the JMD Milling Drilling Machines possess the advantages of space-saving versatility, affordability and light machining capability. Features:- Milling/Drilling Machines

- One-piece cast iron column for added support

- Belt cover quick slide latch allows faster belt adjustment to change spindle speeds

- Base taper allows for easier clean-up

- Larger hand wheel knobs

- UL Listed motor

- Extra large worktable

- Heavy-duty tapered roller bearings support the spindle, resulting in greater tolerance and more accurate drilling depth

- New positive quick-stop knob and easy-to-read internal depth gauge (external on JMD-15)

- 360° head swivel

- Heavy-duty power downfeed with manual fine feed (JMD-18PFN)

- Three power down feeds (JMD-18PFN .004, .007, .01)

- Worklamp

- Adjustable carbide facemill

- Drill press angle vise

- 1/2 drill chuck, chuck arbor

- Draw bar

- Shown with optional base P/N 350045

-

Out of stock

The Rugged frame and base ensure that hardened polished, high-carbon steel rolls on the JET Electrical Power Slip Roll deliver smooth, even results. All electrical and rotating parts are designed to enhance operator safety and comfort during use. Easy setup and operation, this is a must-have for any HVAC or fabrication shop.

The Rugged frame and base ensure that hardened polished, high-carbon steel rolls on the JET Electrical Power Slip Roll deliver smooth, even results. All electrical and rotating parts are designed to enhance operator safety and comfort during use. Easy setup and operation, this is a must-have for any HVAC or fabrication shop. -

Out of stock

-

All electrical and rotating parts are designed for safety and ease of use

-

Cast iron frame

-

Convenient foot-control assembly with emergency-button

-

Easy to setup and operate

-

Forming roll has attached position scale for equal pressure adjustment

-

Forward and reverse action

-

Heavy duty cast iron frame and enclosed base insure precise sheet metal rolling.

-

Perfect tool for sheet metal forming in HVAC and FAB-shops

-

Roll drive is controlled by foot pedal for immediate forward and reverse action

-

-

Out of stock

Achieve precision drilling and tapping from a design that includes an easy-to-read internal depth gauge, power downfeed speed selector, built-in spindle lock and calibrated fine down feed. JET backs this reliable combination drilling and tapping press with a Two Year Warranty.Easily accessible table raiserHead tilts left or rightHeavy-duty design allows a variety of precision drilling and tapping applicationsIntegrated tapping and reversing controlsLarge production table and T-slotted basePower downfeed speed selector

Achieve precision drilling and tapping from a design that includes an easy-to-read internal depth gauge, power downfeed speed selector, built-in spindle lock and calibrated fine down feed. JET backs this reliable combination drilling and tapping press with a Two Year Warranty.Easily accessible table raiserHead tilts left or rightHeavy-duty design allows a variety of precision drilling and tapping applicationsIntegrated tapping and reversing controlsLarge production table and T-slotted basePower downfeed speed selector -

Out of stock

Stock Number 414499 Blade Speeds (SFPM) 100 - 350 Blade Wheel Diameter (In.) 14 Drive Variable Speed Motor (HP) 2 HP, 460V, 3Ph Overall Dimensions (L x W x H) (In.) 75-1/2 x 33 x 41 Prop 65 Cancer and Reproductive Harm Rectangle at 45 Degrees (In.) 6-1/2 x 11 Rectangle at 90 Degrees (In.) 10 x 10 and 7 x 16 Round at 45 Degrees (In.) 10 Round at 90 Degrees (In.) 10 Vise Swivels (Deg.) 45° Weight (Lbs.) 927 -

SuperMax Tools offers a wide variety of SuperBrush™ sanders to meet the many needs of any woodworking shop. Our goal is to provide an excellent priced machine yielding an incredible return on investment by creating faster output, reduced rework, and greater product consistency. Just think of all the applications our machines can help with – here a just a few: • Raw Wood Sanding | White Wood Sanding • Break sharp edges • Blend out minor defects • Sealer Sanding | Primer Sanding | Scuff Sanding • Profile sanding • Clean reclaimed wood • Wire brushing to pull out soft grain to create textured surface These easy to use machines come with an extremely low learning curve and offer many different features which include: quick change brush heads, infinitely variable brush and conveyor speeds to allow for endless finish possibilities, adjustable tension rollers to prevent stock slippage, and precision height adjustments. Our SuperBrush™ sanders come in sizes ranging from 24” to 49” with single and/or double brush head offerings to meet all your finishing needs.Dozens of brush heads available to effectively sand a wide variety of applications.

SuperMax Tools offers a wide variety of SuperBrush™ sanders to meet the many needs of any woodworking shop. Our goal is to provide an excellent priced machine yielding an incredible return on investment by creating faster output, reduced rework, and greater product consistency. Just think of all the applications our machines can help with – here a just a few: • Raw Wood Sanding | White Wood Sanding • Break sharp edges • Blend out minor defects • Sealer Sanding | Primer Sanding | Scuff Sanding • Profile sanding • Clean reclaimed wood • Wire brushing to pull out soft grain to create textured surface These easy to use machines come with an extremely low learning curve and offer many different features which include: quick change brush heads, infinitely variable brush and conveyor speeds to allow for endless finish possibilities, adjustable tension rollers to prevent stock slippage, and precision height adjustments. Our SuperBrush™ sanders come in sizes ranging from 24” to 49” with single and/or double brush head offerings to meet all your finishing needs.Dozens of brush heads available to effectively sand a wide variety of applications.- Raw Wood Sanding | White Wood Sanding

- Break sharp edges

- Open grain for even finish absorption

- Blend out minor defects

- Sealer Sanding | Primer Sanding | Scuff Sanding

- Removes raised fibers and grain (denib/defuzz)

- Degloss previously finished wood

- Clean reclaimed wood

- Wire brushing

- Distress (weathered/Southwest finish)

- Pull out soft grain to create textured surface

- Raw Wood Sanding | White Wood Sanding